Highly impact-resistant polypropylene resin composition and preparation method thereof

A high-impact polypropylene and resin composition technology, applied in the field of synthetic resins, can solve the problems of reduced thermal deformation temperature of polypropylene, poor impact resistance, low toughness, etc., and achieve production cost savings, good compatibility, and improved Effects of toughness and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a high-impact polypropylene resin composition, comprising the following steps:

[0034] a), blending and extruding raw materials to obtain a high-impact polypropylene resin composition;

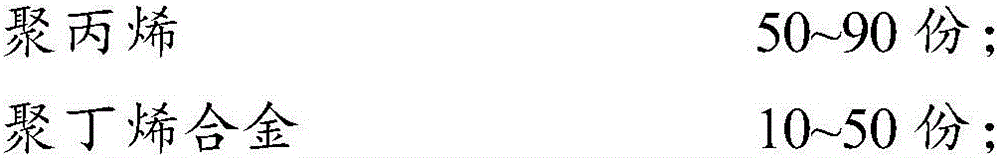

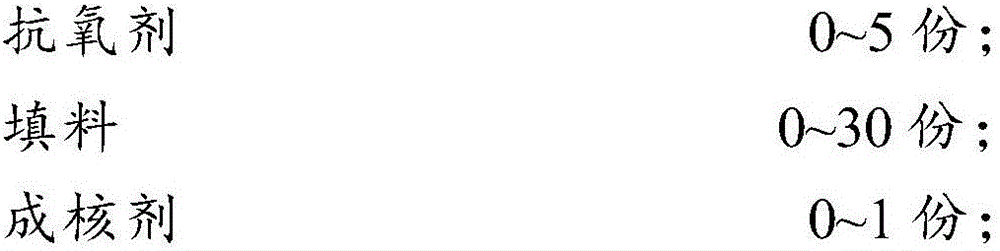

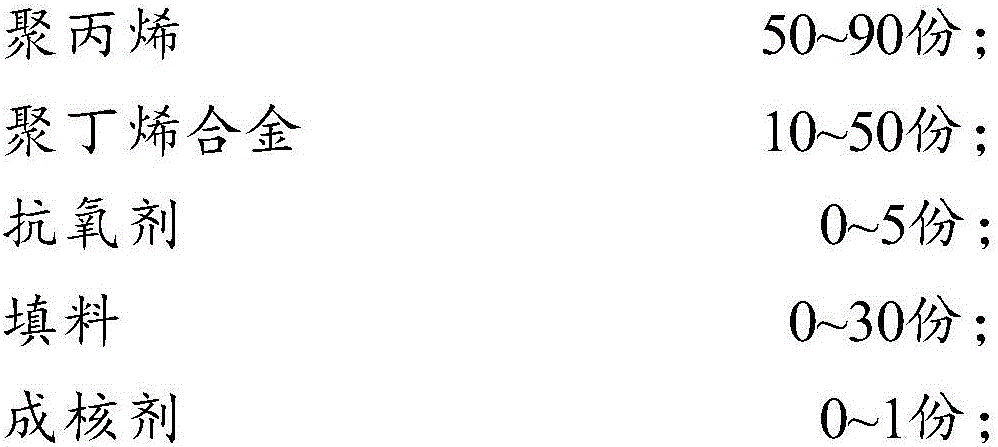

[0035] The raw materials include 50-90 parts by weight of polypropylene, 10-50 parts by weight of polybutene alloy, 0-5 parts by weight of antioxidant, 0-30 parts by weight of filler and 0-1 part by weight of nucleating agent;

[0036] The polybutene content in the polybutene alloy is 60-90 wt%, the polypropylene content is 9.9-35 wt%, and the polybutene-polypropylene block copolymer content is 0.1-5 wt%.

[0037] In the preparation method provided by the invention, the raw materials are directly blended and extruded. Wherein, the raw materials are consistent with the components contained in the above resin composition, and will not be repeated here. In the present invention, the blending extrusion temperature is preferably 170-240°C, more...

Embodiment 1

[0041] 1) Composition design:

[0042]

[0043] 2) Prepare the resin composition:

[0044] According to the design composition in 1), feed the raw materials into a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature of zone 4 is set to 205°C, the temperature of zone 5 is set to 210°C, the temperature of zone 6 is set to 205°C, the temperature of the head is set to 200°C, and the screw speed is set to 195r / min. The raw materials are blended and extruded in a twin-screw extruder to obtain a high-impact polypropylene resin composition.

Embodiment 2

[0046] 1) Composition design:

[0047]

[0048]

[0049] 2) Prepare the resin composition:

[0050] According to the design composition in 1), feed the raw materials into a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature of zone 4 is set to 215°C, the temperature of zone 5 is set to 220°C, the temperature of zone 6 is set to 225°C, the temperature of the head is set to 210°C, and the screw speed is set to 205r / min. The raw materials are blended and extruded in a twin-screw extruder to obtain a high-impact polypropylene resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com