Automatic u-shape shaping device

A shaping device, U-shaped technology, applied in the direction of feeding device, positioning device, storage device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

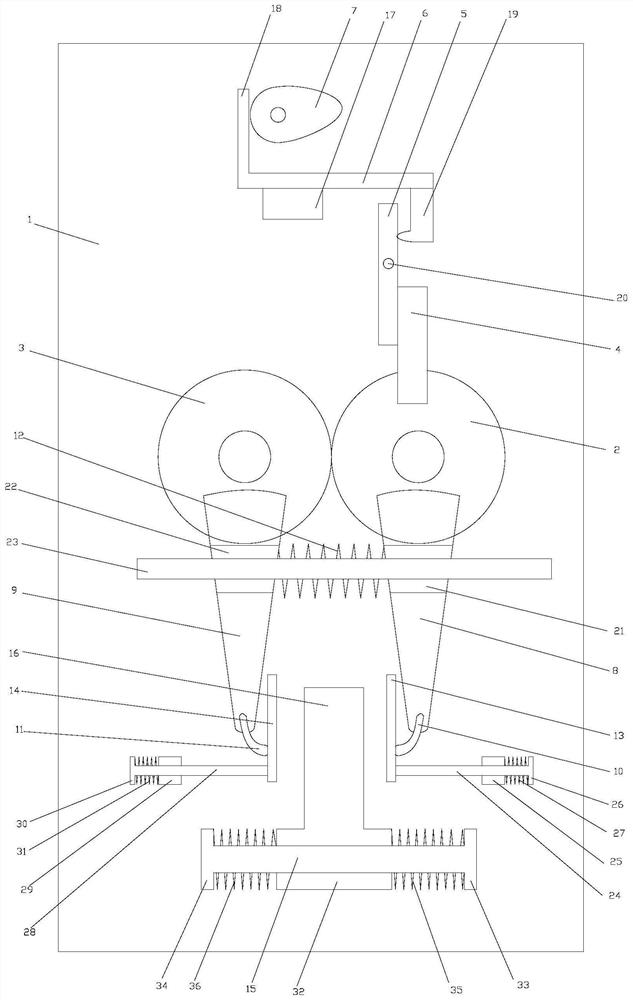

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

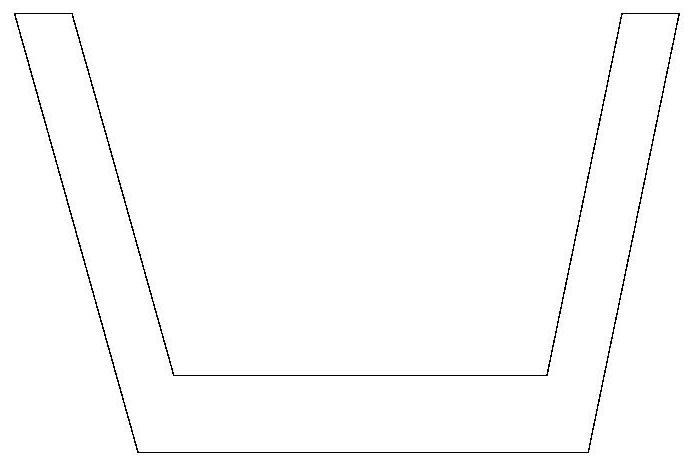

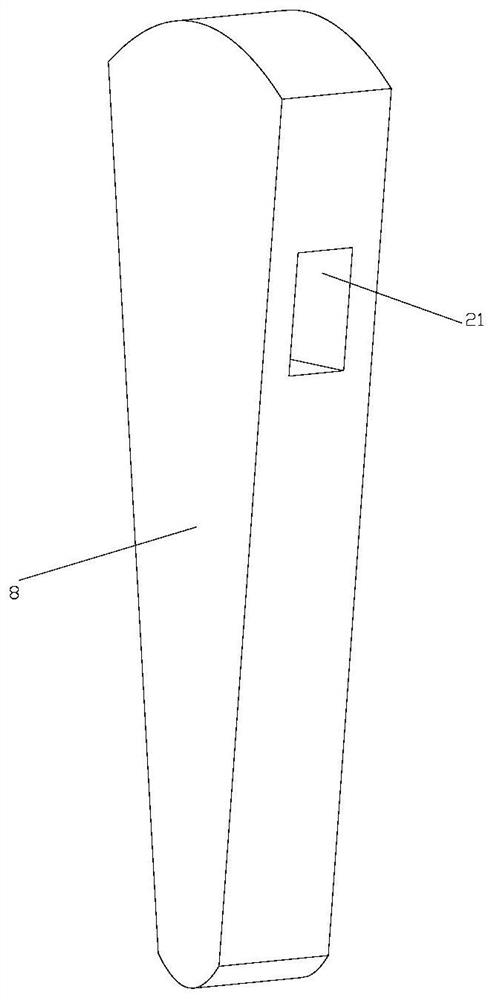

[0013] As shown in the figure, the automatic U-shaped piece shaping device of the present invention includes a workbench 1, on which a first gear 2 and a second gear 3 that mesh with each other are rotatably connected, and the first gear 2 is rotatably connected to the On the workbench 1, the second gear 3 is rotatably connected to the workbench 1 through the second rotary shaft. The drive plate 5 is connected to the upper part for rotation, and the slide plate 6 for pulling the drive plate 5 to rotate is slidably connected to the workbench 1. The lower end of the drive plate 5 is in close contact with the plectrum 4, and the workbench 1 is provided with a cam for driving the slide plate 6 to slide. 7. The workbench 1 is provided with a motor for driving the cam 7 to rotate, and the motor is connected to an external power supply to work; the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com