Method of thermal crystallization treatment for cylindrical mouthpart of preform

A treatment method and preform technology, which is applied in the field of thermal crystallization treatment, can solve problems such as the discrepancy between the size of the bottle mouth and the design value, and achieve the effect of preventing irregular deformation and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

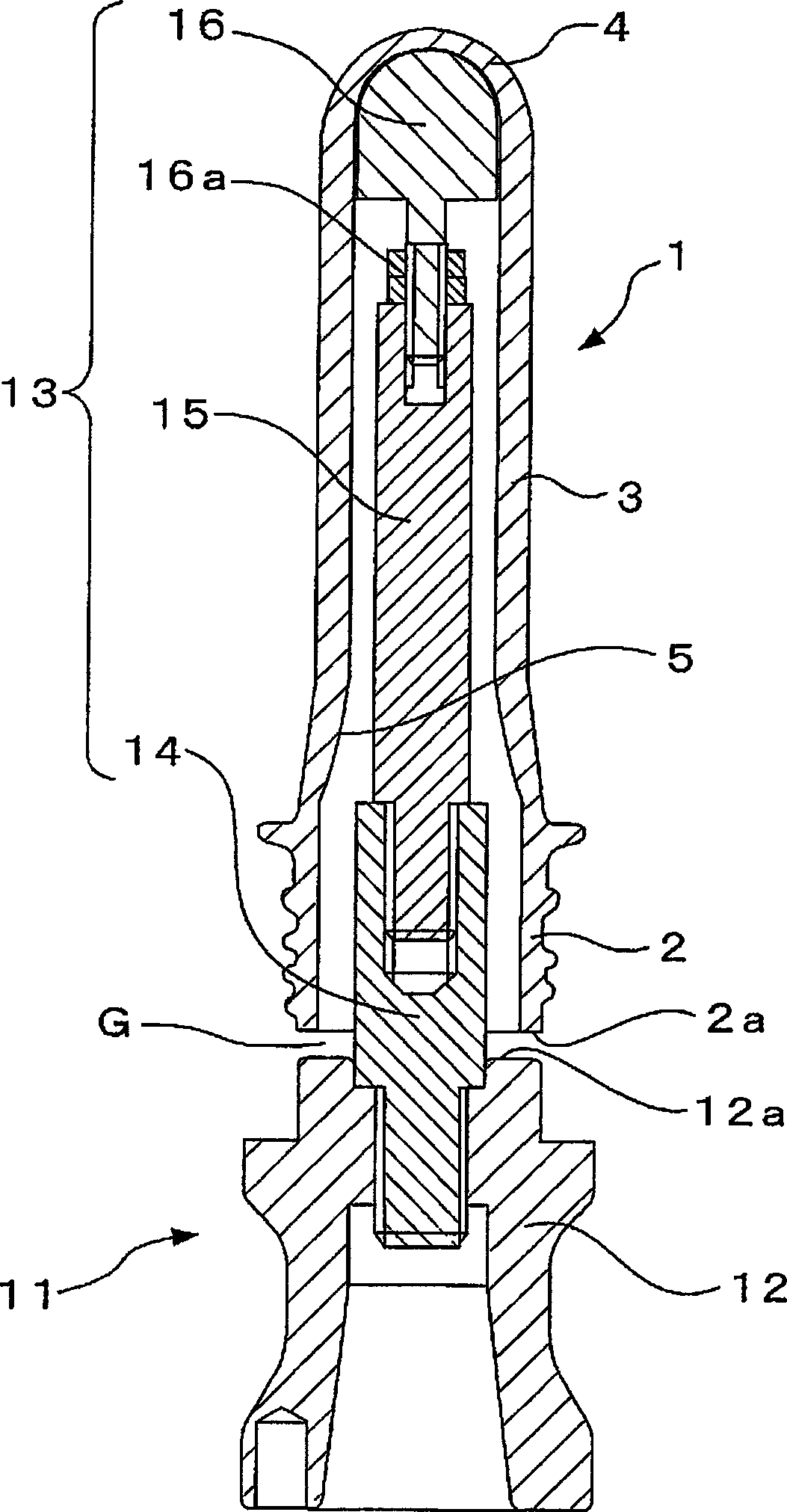

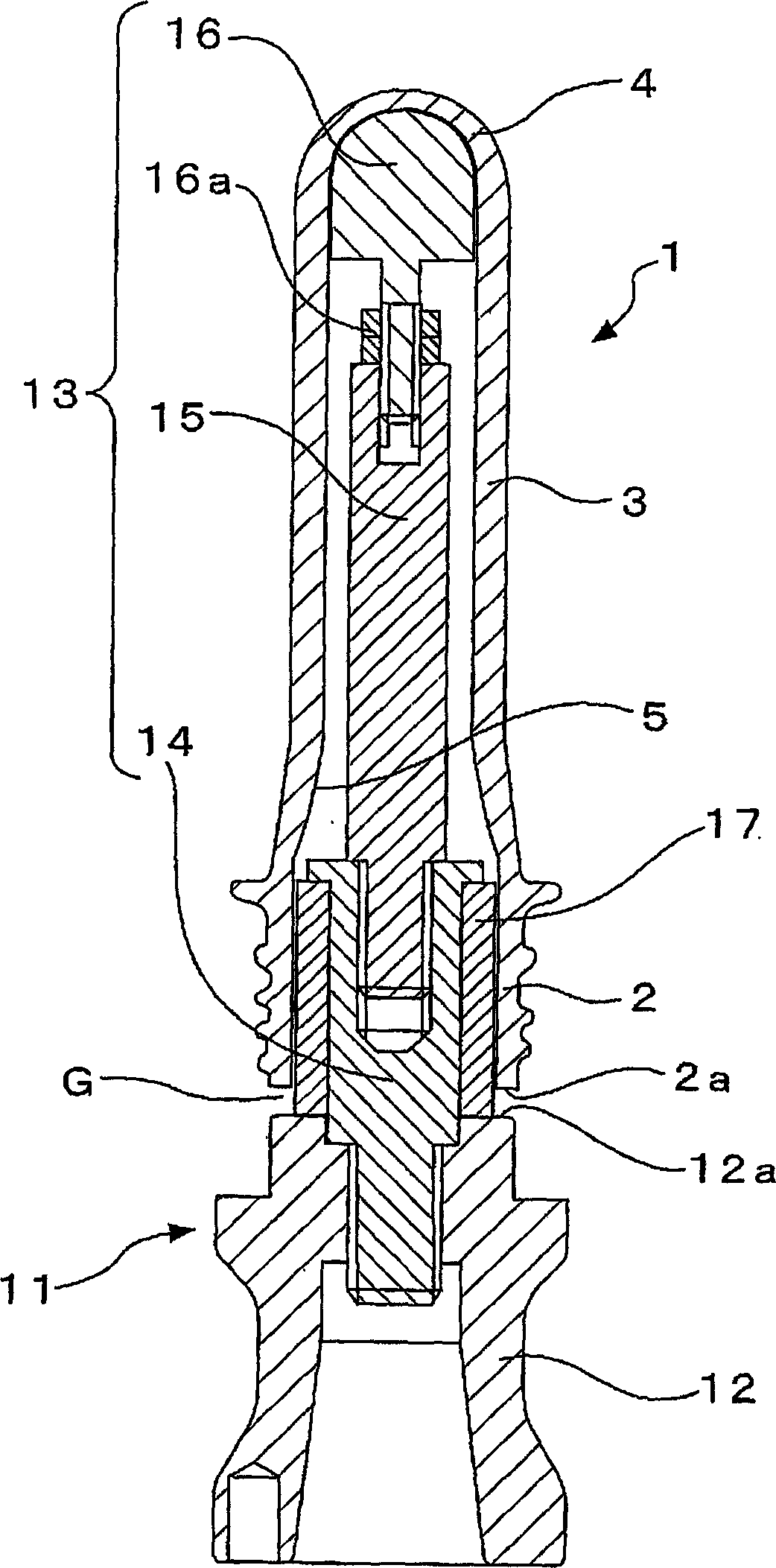

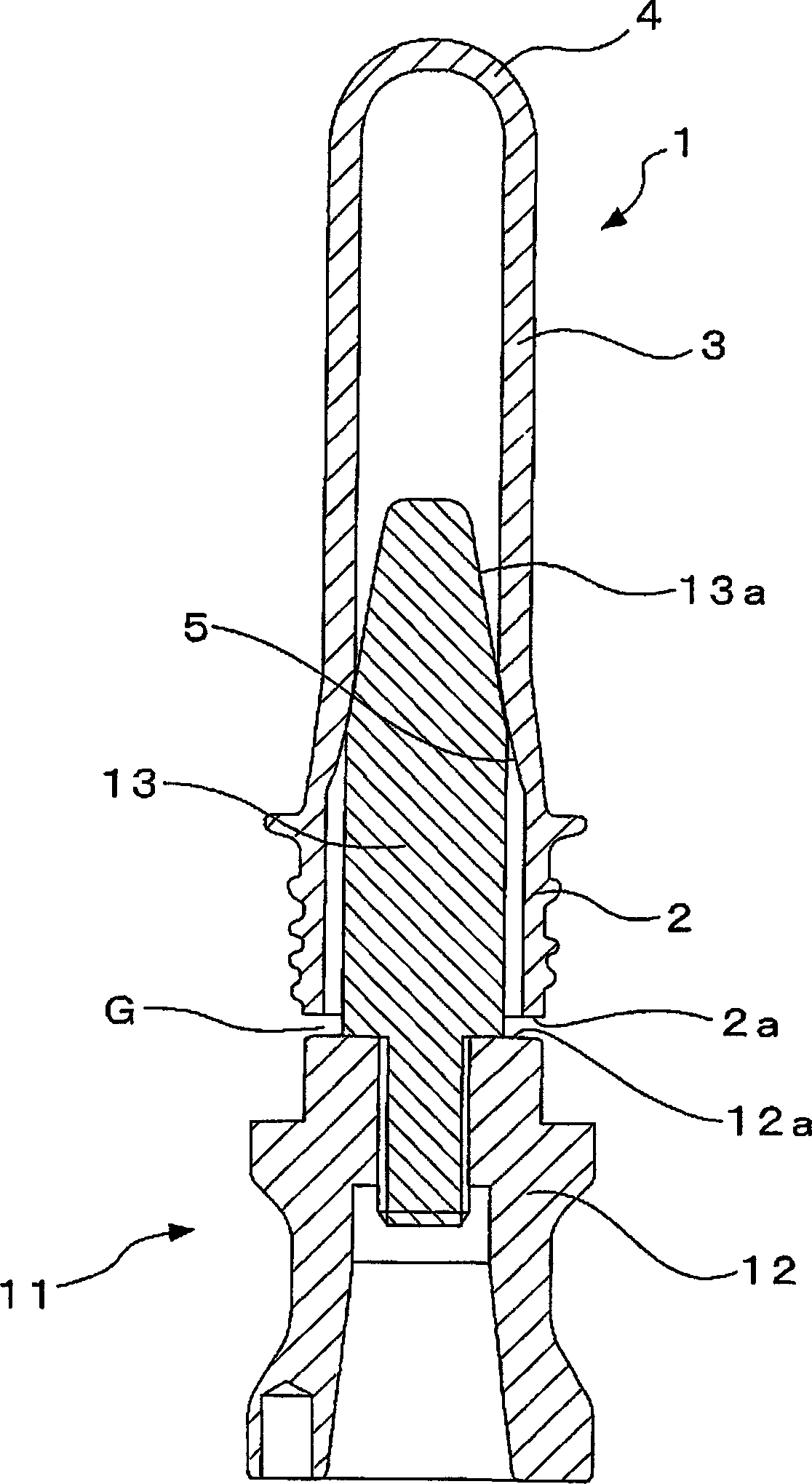

[0044] figure 1 Shown is the first example of the jig used in the present invention for the thermal crystallization treatment of the neck portion of the preform made of PET resin. Sectional front view.

[0045] The jig 11 has the following structure: a top-cylindrical jig base 12 is assembled on the conveying device omitted in the figure, and the supporting body 13 is erected from the center of the top surface of the jig base 12 along the central axis. set up. In the first example, the support body 13 includes: a support base 14 that is screwed on the fixture base 12; a support rod 15 that is screwed on the support base 14; Combined with the front hemispherical portion 16 on the support rod 15, the double nuts 16a can adjust the overall height of the support body 13.

[0046] From figure 1 It can be judged that in the state where the preform 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com