Powder distributor for placing target material green body, positioning piece and sintering method of rotating target material

A sintering method and target raw technology, applied in the field of ceramic target sintering, can solve the problems of poor slippage effect, difficulty in effectively preventing irregular deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The invention will be described in further detail below in conjunction with specific embodiments.

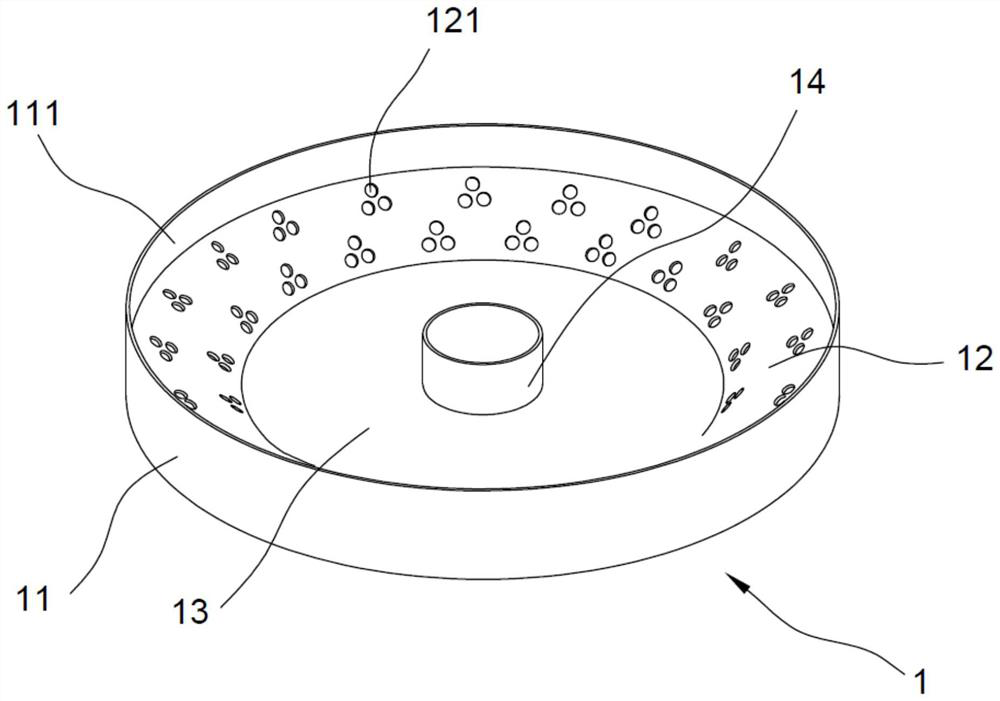

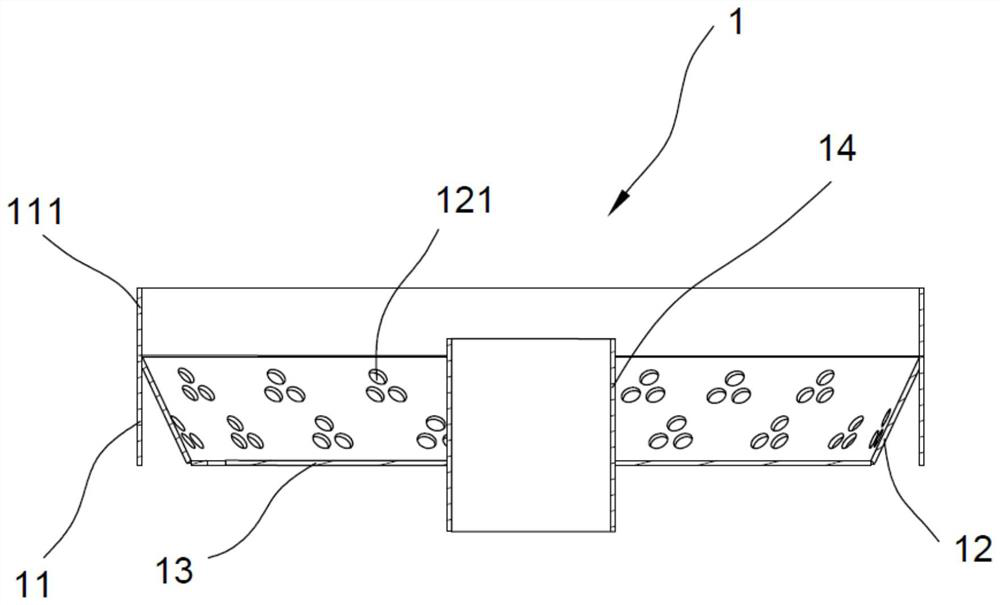

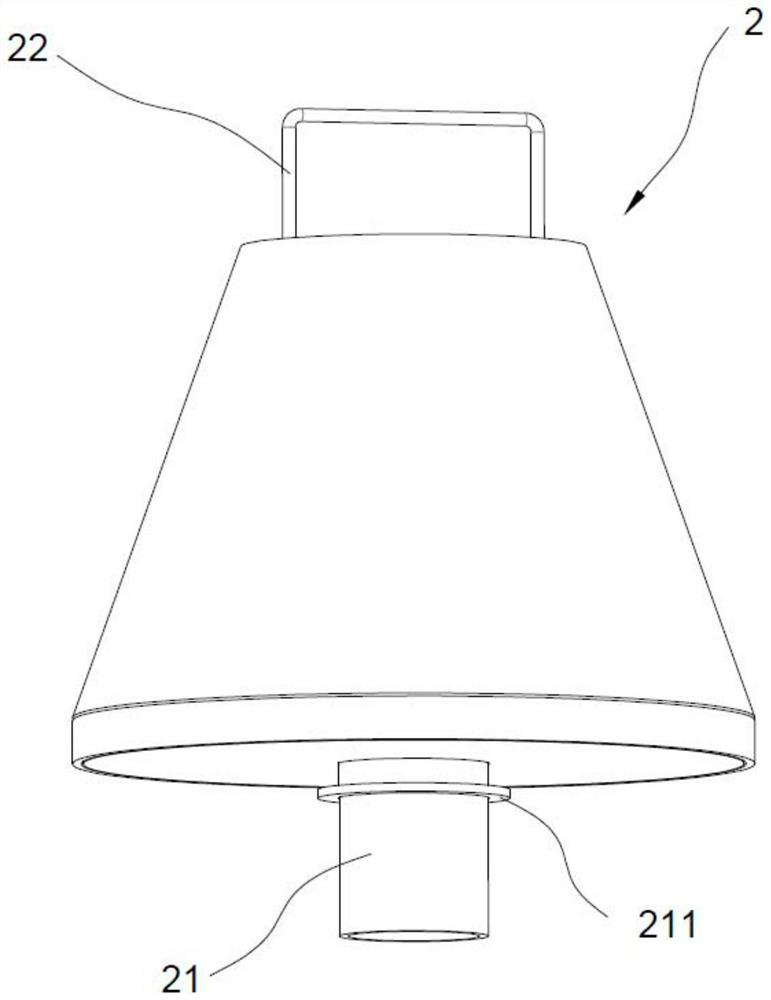

[0011] The bearing surface of the setter plate is provided with a positioning concave hole, which is a through hole. use as figure 1 with figure 2 In the shown powder distributor 1 , the center of the powder distributor 1 protrudes downwards with a tubular central positioning part 14 , and its lower end protrudes downwards. Put powder distributor 1 on the setter. The center positioning portion 14 of the powder distributor 1 is inserted into the positioning concave hole of the setter, whereby the powder distributor 1 is fixed on the setter.

[0012] The powder distributor 1 includes a distribution orifice plate 12 and a vertical peripheral riser 11, both of the distribution hole plate 12 and the peripheral riser 11 are closed circular rings, and the end of the distribution hole plate 12 is connected to the waist of the peripheral riser 11 away from the center , the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com