Air suction inverted twisting type single-sheet feeding device

A paper feeding device and single-sheet technology, applied in transportation and packaging, object separation, pile separation, etc., can solve the problems of double or multiple paper feeding, slow paper feeding speed, broken invoice numbers, etc., to avoid paper runaway effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

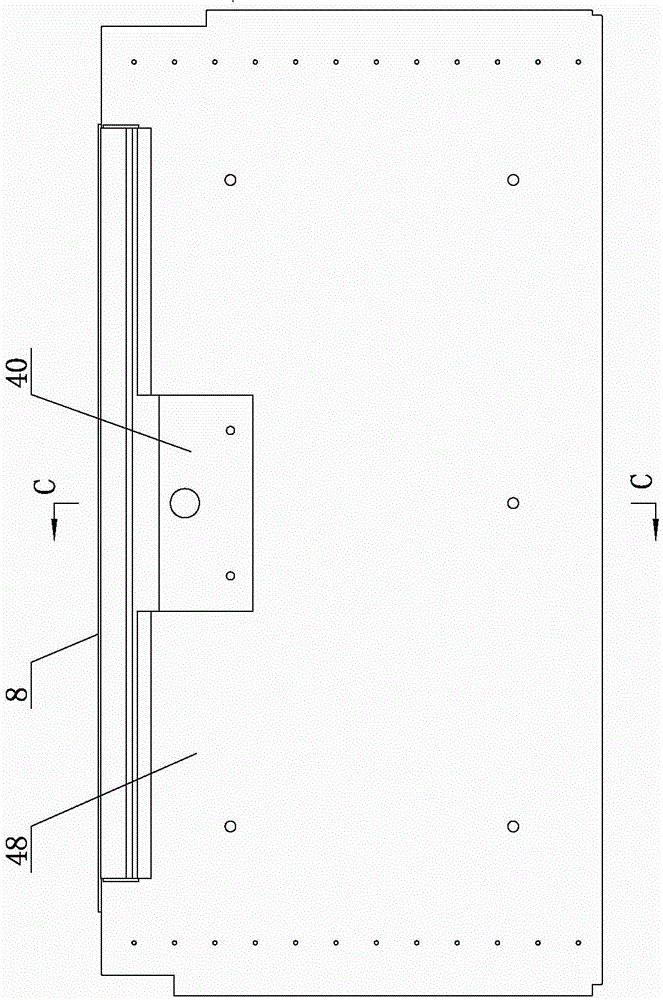

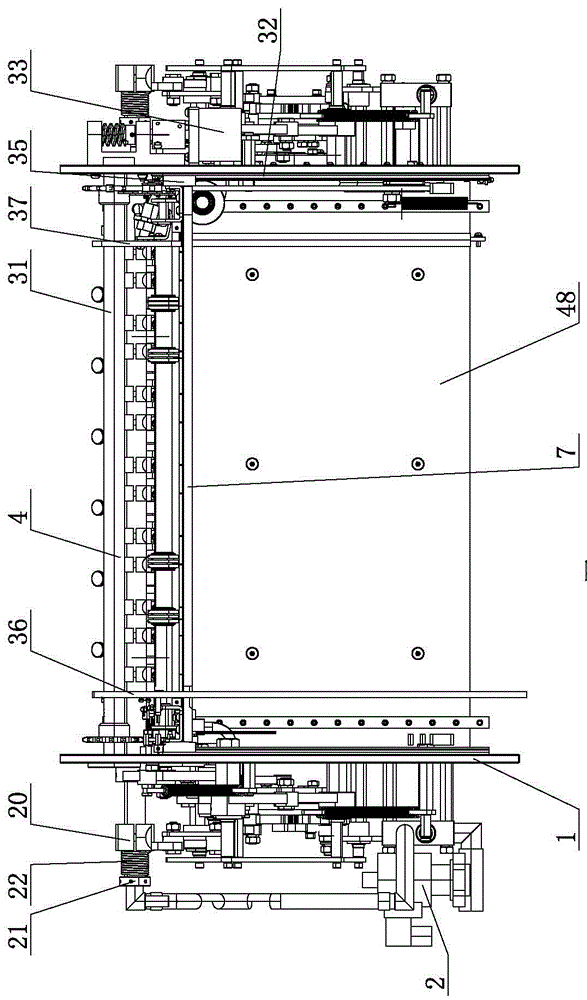

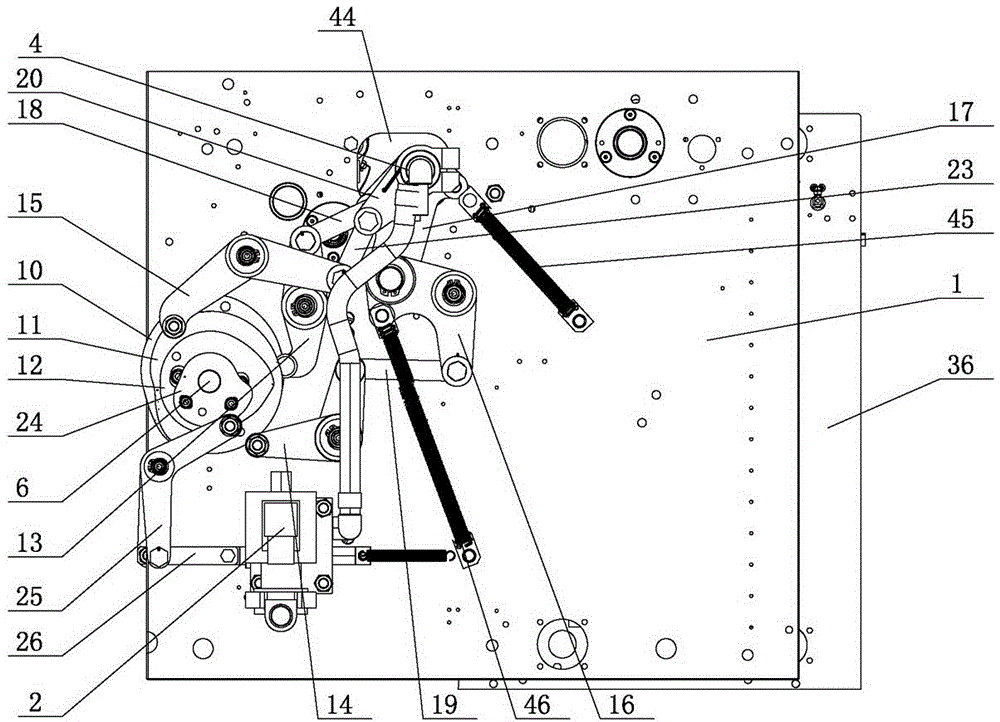

[0016] The air-suction reverse-twisting single-fed paper feeding device of the present invention, such as figure 1 Shown includes paper table. The paper feeding table is composed of a frame, a lifting mechanism and a paper feeding board 7 . It also includes a suction nozzle fixing device composed of at least two suction nozzles 9 fixed on the suction nozzle air guide pipe 4 . The suction nozzle 9 sucks the topmost first sheet of paper from the pile of paper stacked on the paper feeding table, and multiple cam drive mechanisms drive the suction nozzle air guide tube 4 to complete the lifting and swinging action. When the swing reaches the maximum position , the first air valve 2 closes the suction, releases the sucked paper, and transfers it to the paper receiving mechanism, thereby completing a paper feeding process; the suction nozzle air guide tube 4 drives the suction nozzle 9 back to the initial state, and starts the next action Loop to pick up the next sheet. The fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com