Dual-structure container with inner bag container having excellent regular contractility

A container and inner bag technology, which is applied in the field of double-structured containers, can solve problems such as difficulty in discharging the content liquid, and achieve the effects of stable discharge, favorable manufacturing cost, and avoidance of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] The excellent effects of the present invention will be described with reference to the following experimental examples.

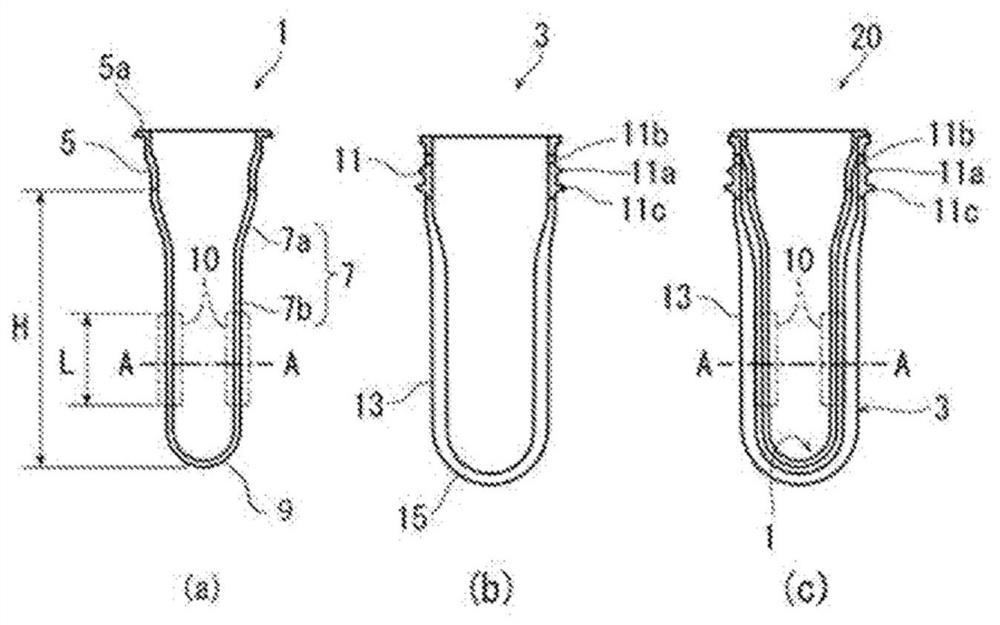

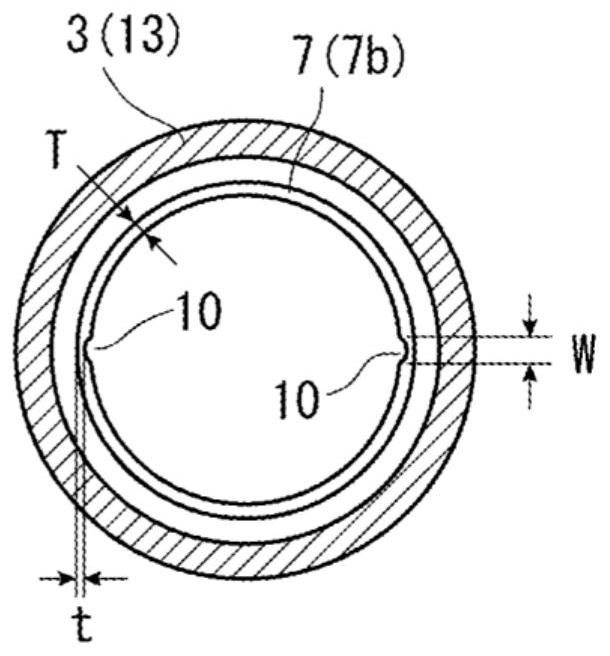

[0114] A commercially available PET resin for bottles (intrinsic viscosity: 0.84 dl / g) sufficiently dried in a dehumidifying dryer was supplied to a hopper of an injection molding machine to obtain a preform for molding a test tube-shaped outer container and for molding A preform of a test tube-shaped inner bag container. A plurality of shrinkage control grooves are axially symmetrically formed on the inner surface of the inner bag container preform. The shape and number of slots are shown in Table 1.

[0115] [Table 1]

[0116]

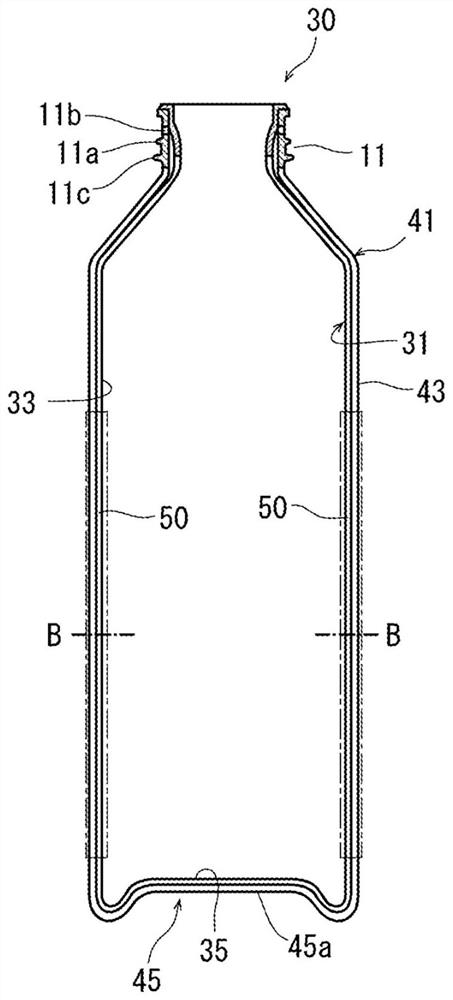

[0117] The inner bag container preform is inserted into the outer container preform to obtain a stacked preform. The stacked preforms were heated by using a quartz heater and a heating iron core, and then blow molded to obtain a cylindrical bottle with an internal volume of about 400 ml. For the outer preform, the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com