Stent

A cylindrical, split-body technology, applied in the field of stents, can solve the problems of stents being unable to resist compressive force, insufficient structural stability, and reduced rigidity, and achieve excellent adaptability, avoid irregular deformation, and prevent irregular deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described below with reference to the drawings.

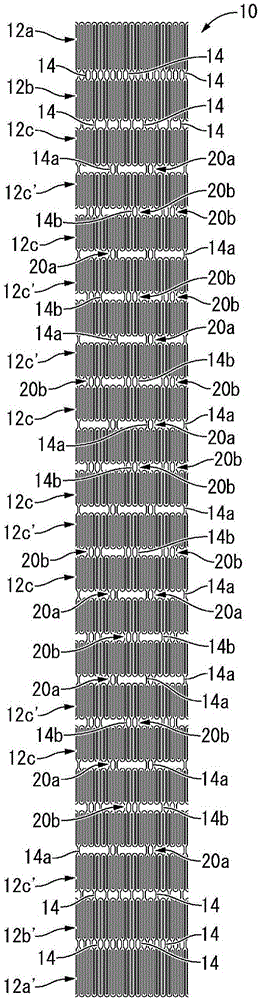

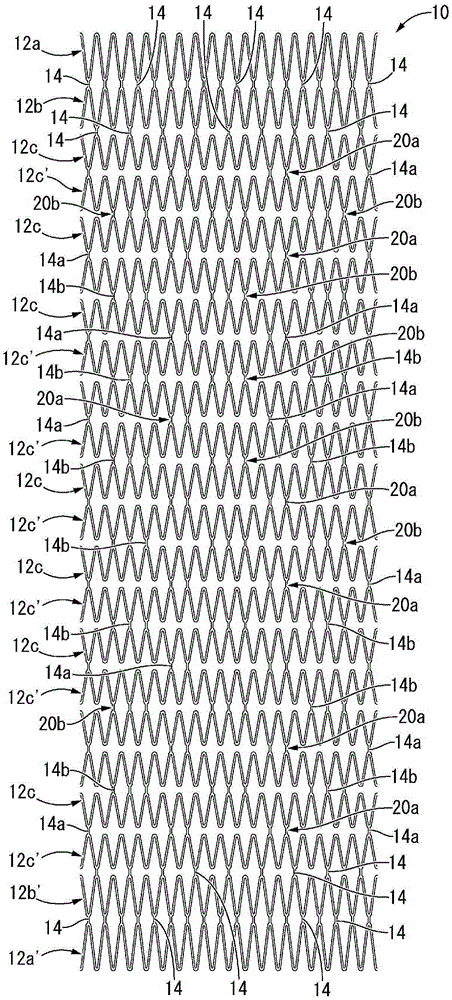

[0055] figure 1 The stent 10 is shown in a reduced-diameter state before expansion as a first embodiment of the present invention. The stent 10 having an approximately cylindrical shape as a whole has a structure in which a plurality of cylindrical divided bodies 12 are arranged in the axial direction, and the plurality of cylindrical divided bodies 12 are connected to each other by a connecting portion 14 .

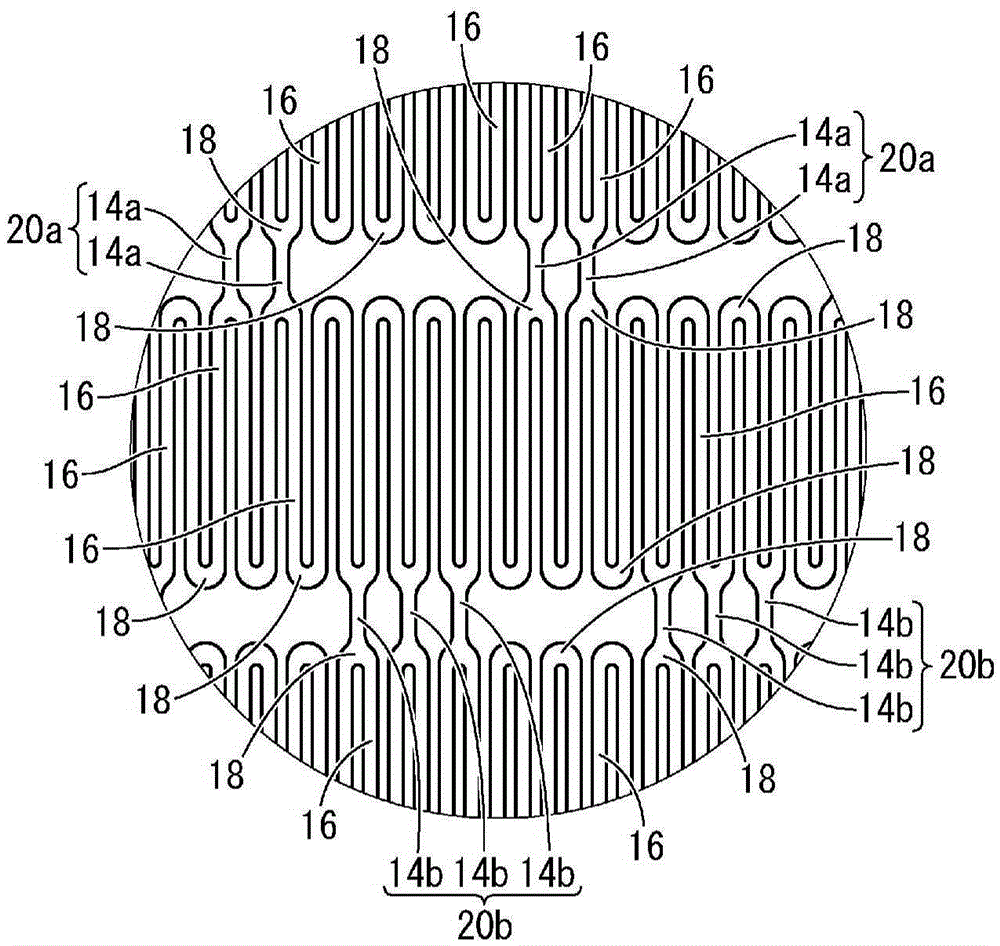

[0056] In more detail, the cylindrical divided body 12 is provided with a plurality of linear portions 16 arranged at equal intervals on the periphery. Such as figure 2 As shown, the linear portion 16 is in the form of an elongated plate extending almost linearly in the axial direction, and a plurality of linear portions 16 are arranged at given intervals in the circumferential direction.

[0057] Also, the linear portions 16 adjacent to each other are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com