Detachable spiral heat exchanger and manufacturing method thereof

A detachable, heat exchanger technology, applied in the field of machinery, can solve the problems of easy leakage points in welding, uneven winding of heat exchange plates, and different widths of welding seams at the edges of heat exchange plates, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

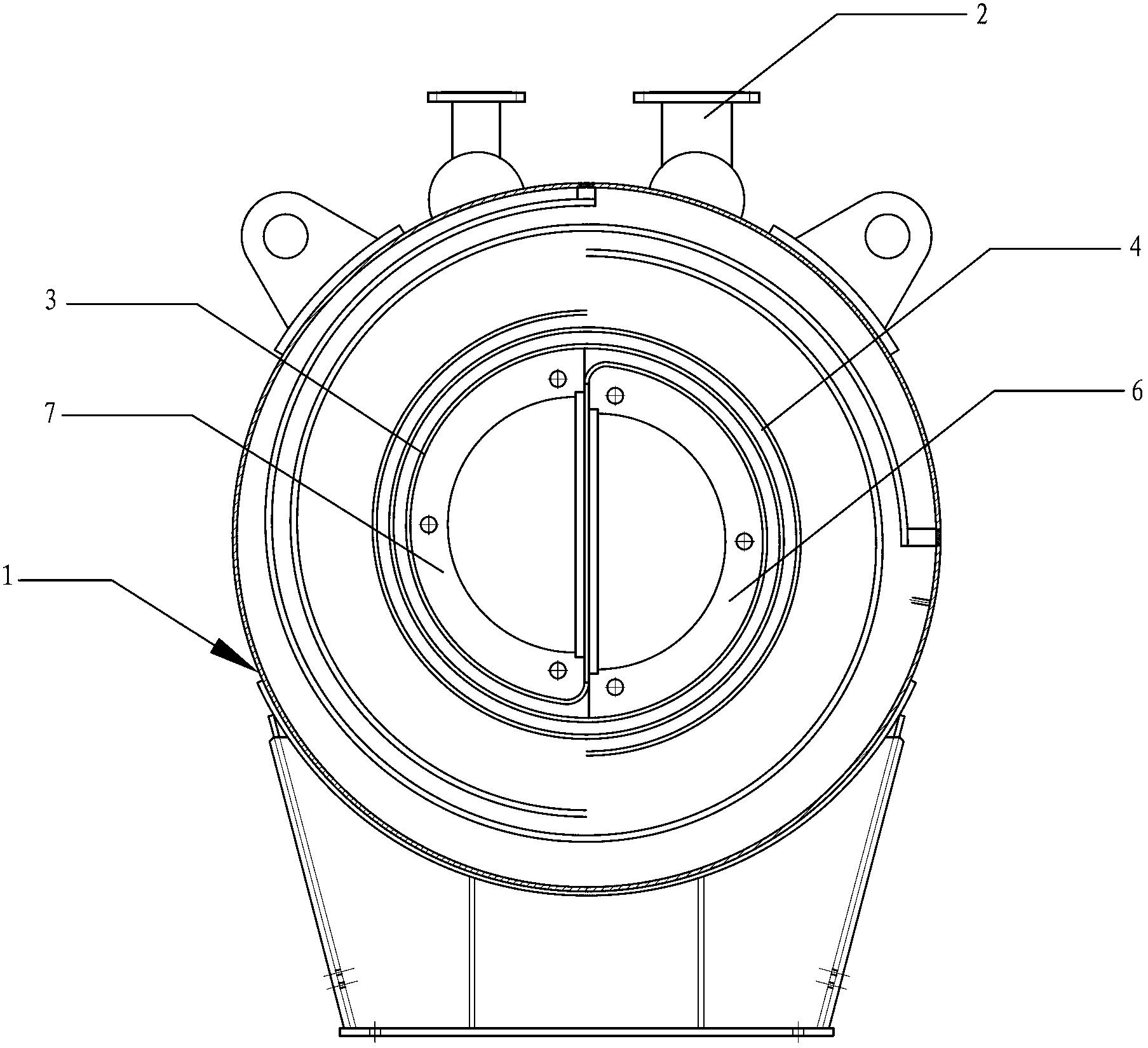

[0020] Embodiment one: see attached figure 1 shown.

[0021] A detachable spiral heat exchanger, which includes a shell 1, two pairs of outlets (not shown in the figure) and inlets 2 arranged on the shell 1, a first heat exchange plate 3 and The second heat exchange plate 4 also includes a support frame, a partition plate 5 is arranged in the support frame, and the first heat exchange plate 3 and the second heat exchange plate 4 are spirally wound around the support frame as the center, The first heat exchange plate 3 and the second heat exchange plate 4 are respectively fixedly connected to the two sides of the separator, and the gap between the first heat exchange plate 3 and the second heat exchange plate 4 is divided into independent first heat exchange plates. channel and the second heat exchange channel.

[0022] The support frame includes a semi-cylindrical hollow first support frame 6 and a second support frame 7 , the first support frame 6 and the second supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com