Construction method of outer wrapped concrete obliquely pulling and buckling and ring and section dividing combination method

A technology of outsourcing concrete and sub-combination, which is applied in construction, bridge construction, bridges, etc., can solve the problems of difficult control of steel pipe and concrete stress in the pipe, large material consumption, and high safety risk, so as to facilitate the design of mix ratio, shorten the construction period, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

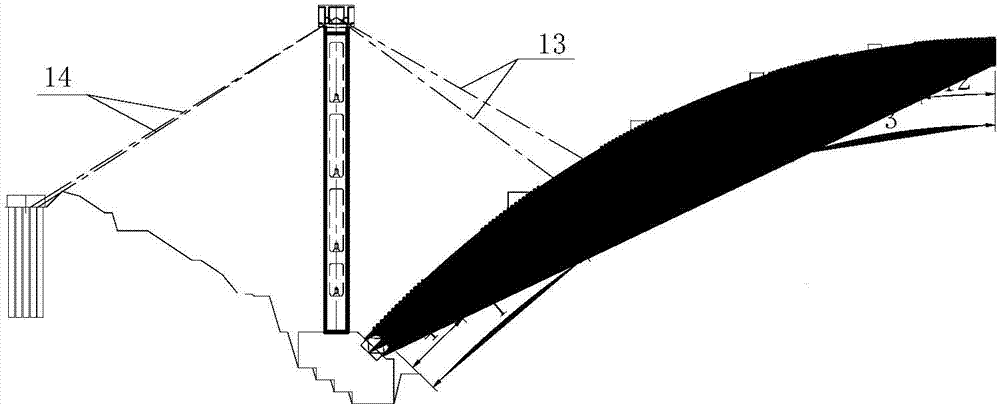

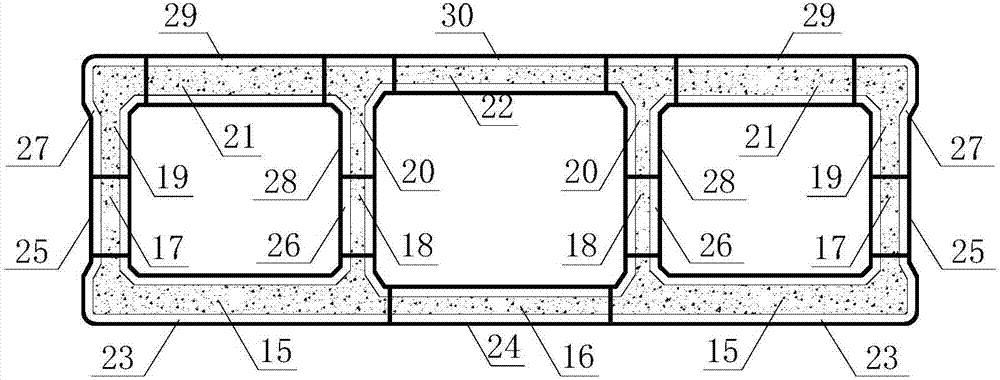

[0017] A construction method of outsourcing concrete cable-stayed buckle-hanging and sub-ring and segmental combination method. According to the structural characteristics of a reinforced concrete arch bridge with three rooms in a single box, the outsourcing concrete must be poured in separate rings. The whole bridge is divided into 6 rings, which are the bottom plate of the side box and the lower belly Plate, upper web, side box top plate, middle box bottom plate and middle box top plate. The specific construction process is:

[0018] 1. Firstly, calculate according to the actual conditions of large-span and large-height-difference construction on site, and determine the reasonable sub-ring and sub-section method, the arrangement method and cable force of buckle cable 13 and balance cable 14, and the whole bridge is divided into 6 rings, each ring and a half The arch rib is divided into 3 working faces and 9 pouring sections, each working face is divided into 3 sections, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com