Equal biaxial tensile test device

A test device, biaxial stretching technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problems of inconvenient operation, complicated device, size limitation, etc., to avoid uneven deformation, The effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

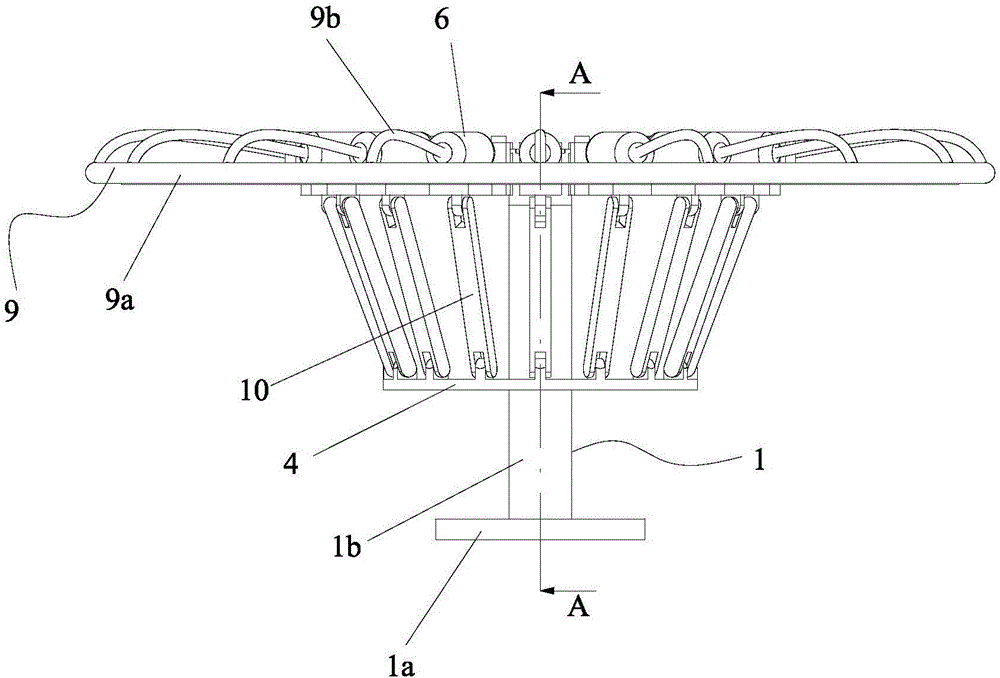

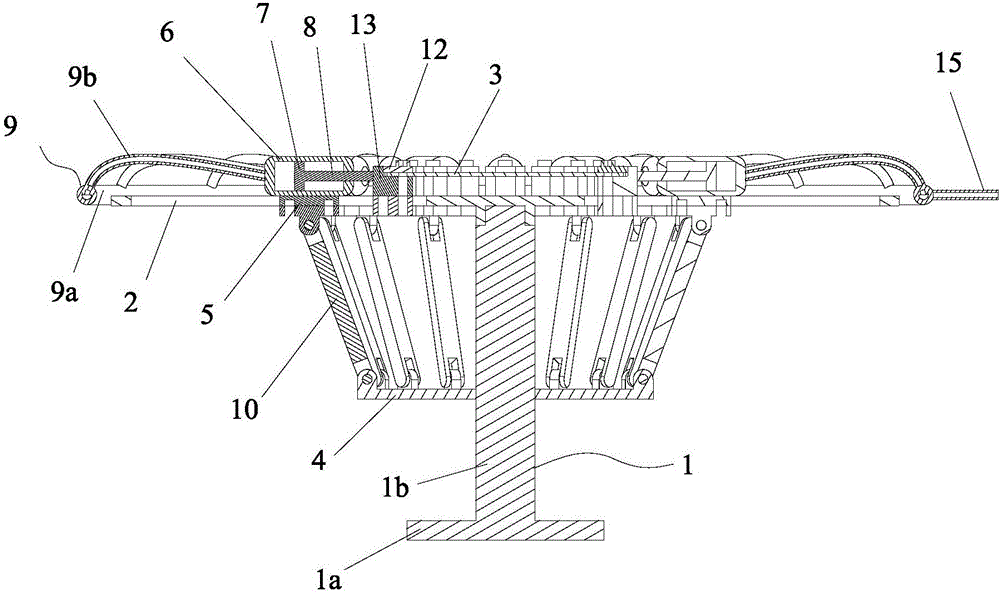

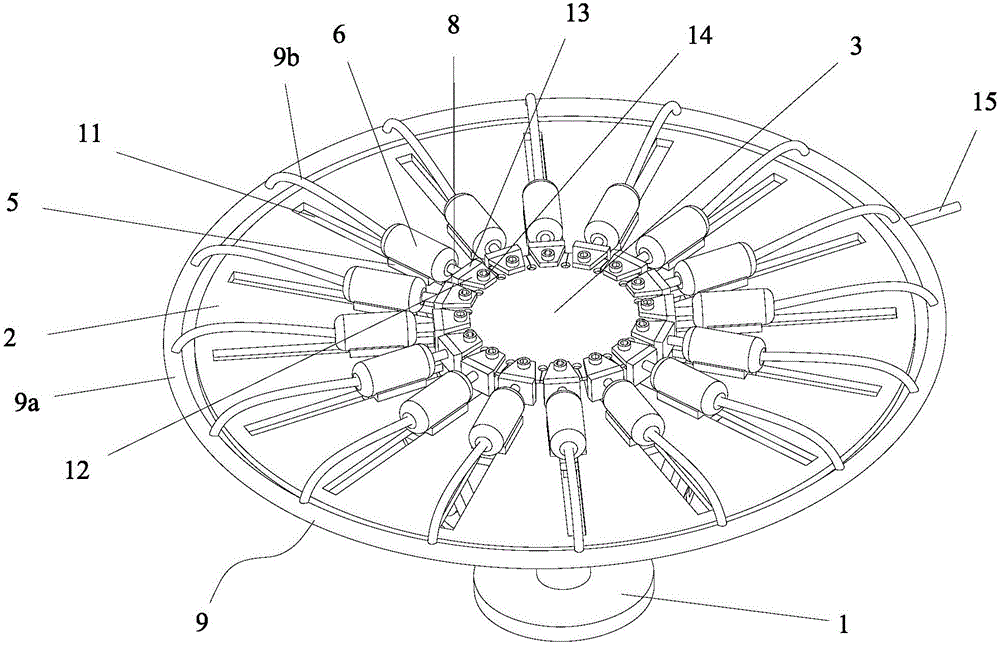

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as Figure 1~5 Shown, a kind of equal bidirectional tensile test device comprises a base 1, a horizontal support plate 2 fixedly arranged on the base 1 for placing a test piece 3 to be tested, a plurality of connection mechanisms connected with the test piece 3 and multiple The traction disc 4 connected with each connecting mechanism, the traction disc 4 is a circular traction disc, each connecting mechanism includes a clamping unit for clamping the test piece 3, a transmission unit connected with the clamping unit and two ends connected to the transmission unit respectively The traction unit connected to the traction disc 4, the transmission unit includes a slider 5 that is slidably connected to the support plate 2, a hydraulic cylinder 6 with an inner cavity fixed on the slider 5, a piston 7 arranged in the hydraulic cylinder 6, and One end is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com