Structural horizontal or vertical and rotatable shock insulation, damping and energy consumption structural system

A technology of vertical and horizontal seismic isolation, applied in the direction of earthquake resistance and building components, which can solve the problems of increasing energy consumption capacity and insufficient anti-overturning moment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

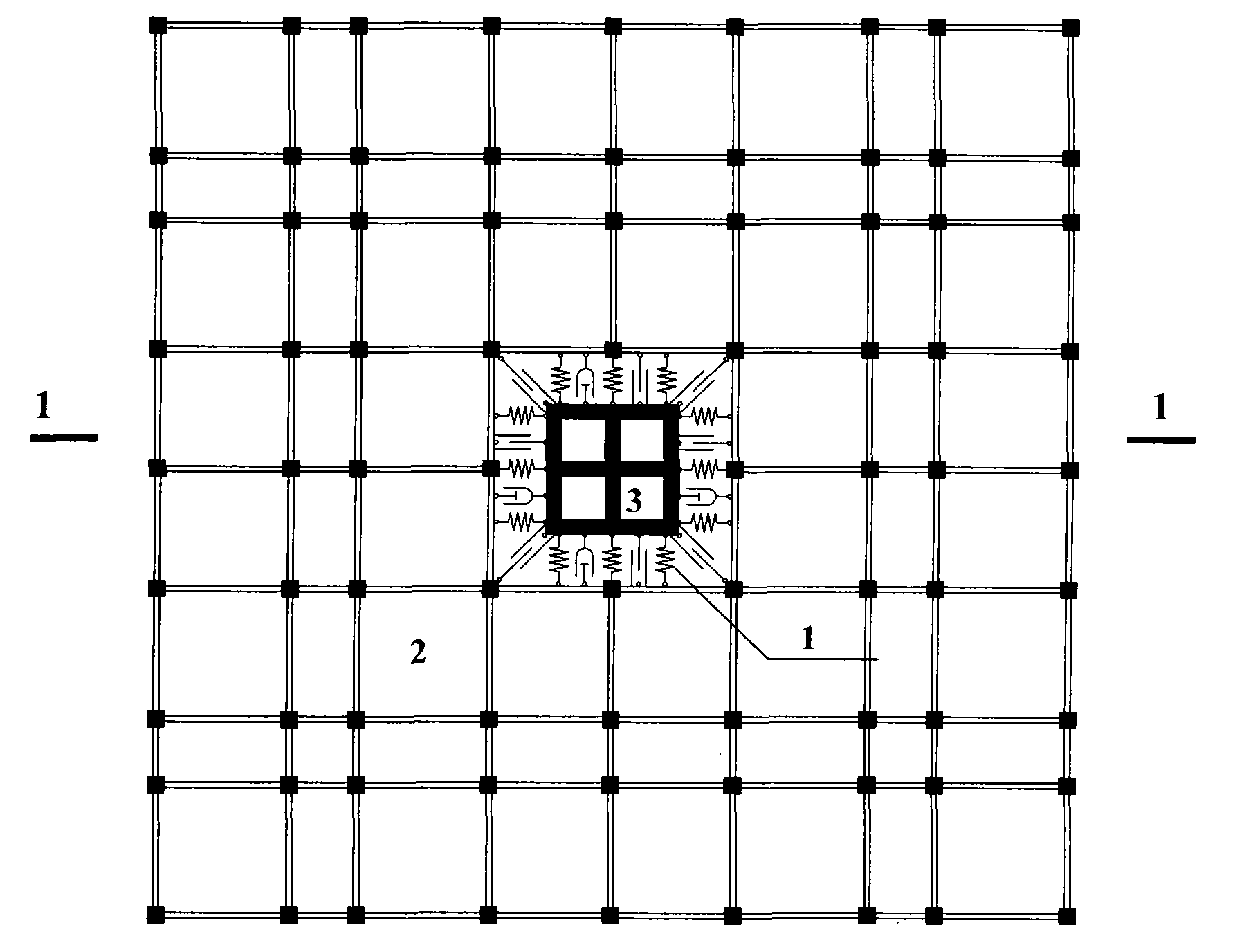

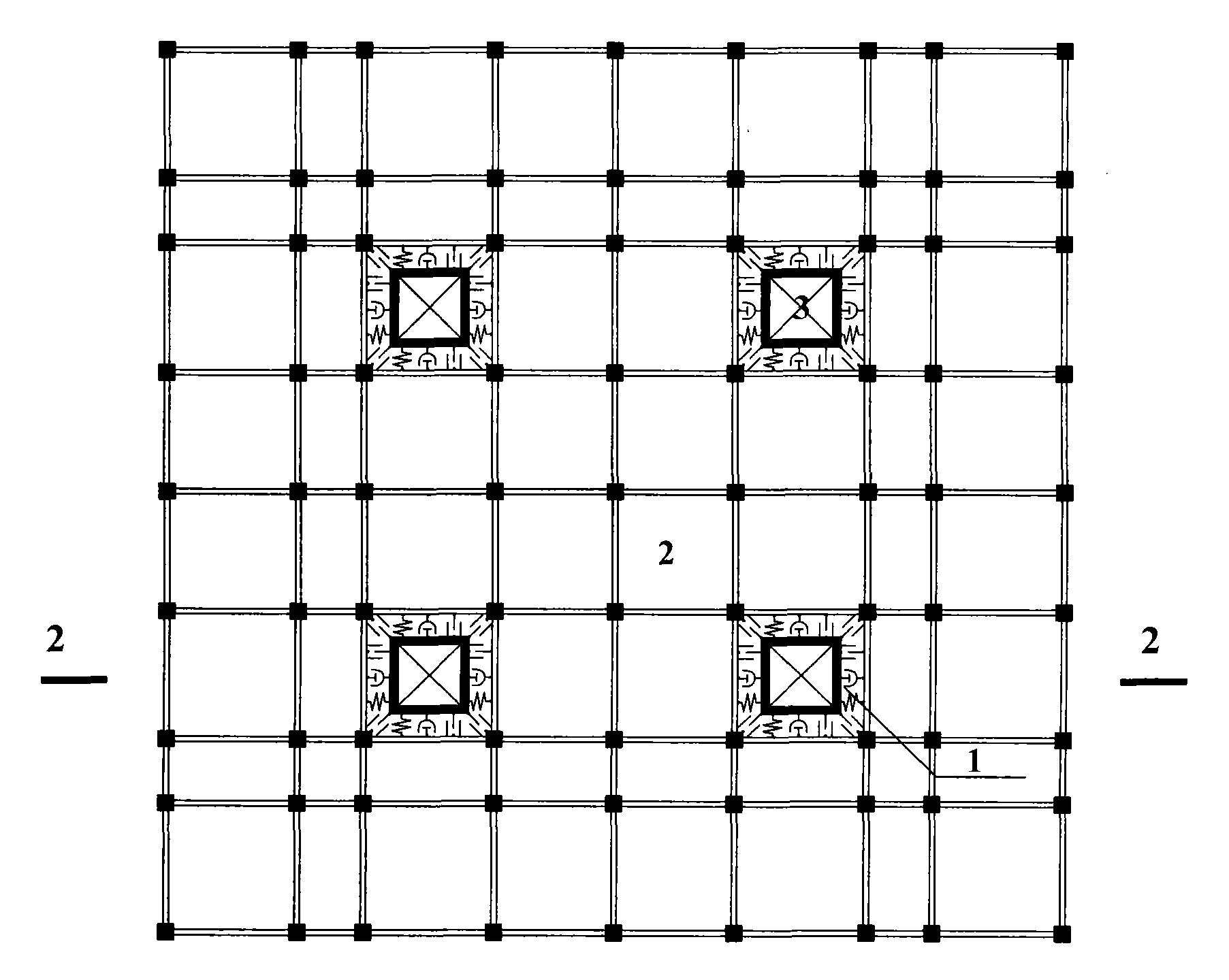

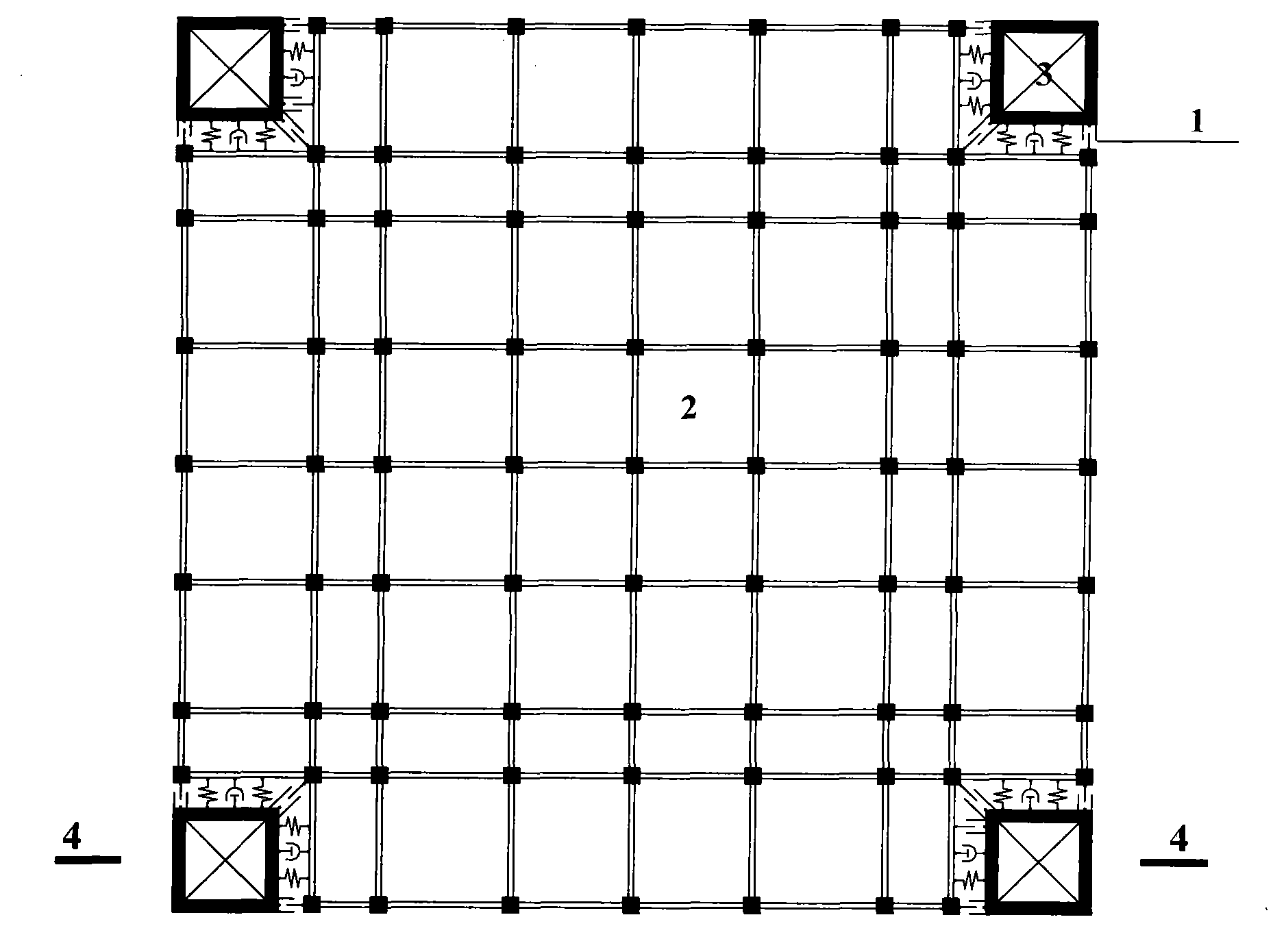

[0051] exist Figure 5 to Figure 35 Among them, when the seismic isolation layer adopts the conventional seismic isolation layer setting method, it can be set at the bottom of the building or in the middle. It can be set up with one layer or multiple layers. For example, the support can be rubber bearing, friction bearing , Rolling bearings, sliding bearings, pendulum bearings, pendulum bearings.

[0052] Figure 10 ~ Figure 12 , Figure 41 In , when the vertical section is an arc-shaped rotating shock-isolation or shock-absorbing or energy-dissipating layer, when the shock-isolation, shock-absorbing, and energy-dissipating supports are installed, the supports are installed and constructed according to the design inclination angle. Figure 21 to Figure 24 In , when a shock-isolation, shock-absorbing or energy-dissipating layer with arc-shaped rotation shock-isolation or shock-absorbing and energy-dissipating capabilities is installed, the shock-isolation, shock-absorbing or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com