Manufacturing method for preventing damper deformation

A production method, elastic wave technology, applied in the direction of electrical components, sensors, etc., can solve the problems of cotton cloth tearing, uneven shrinkage force, breakage, etc., and achieve the best fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

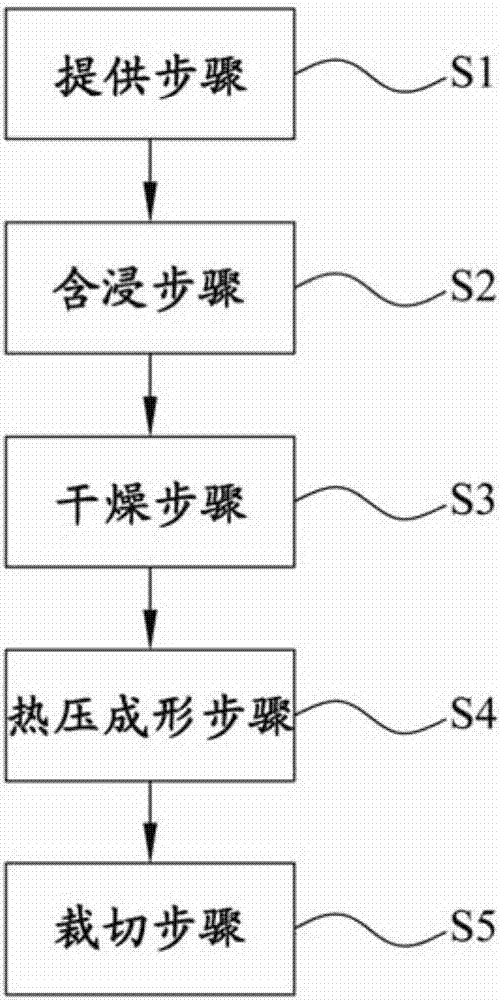

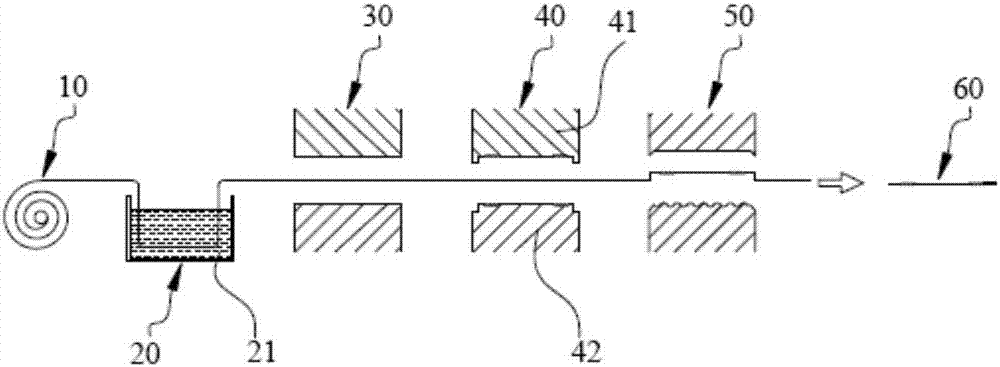

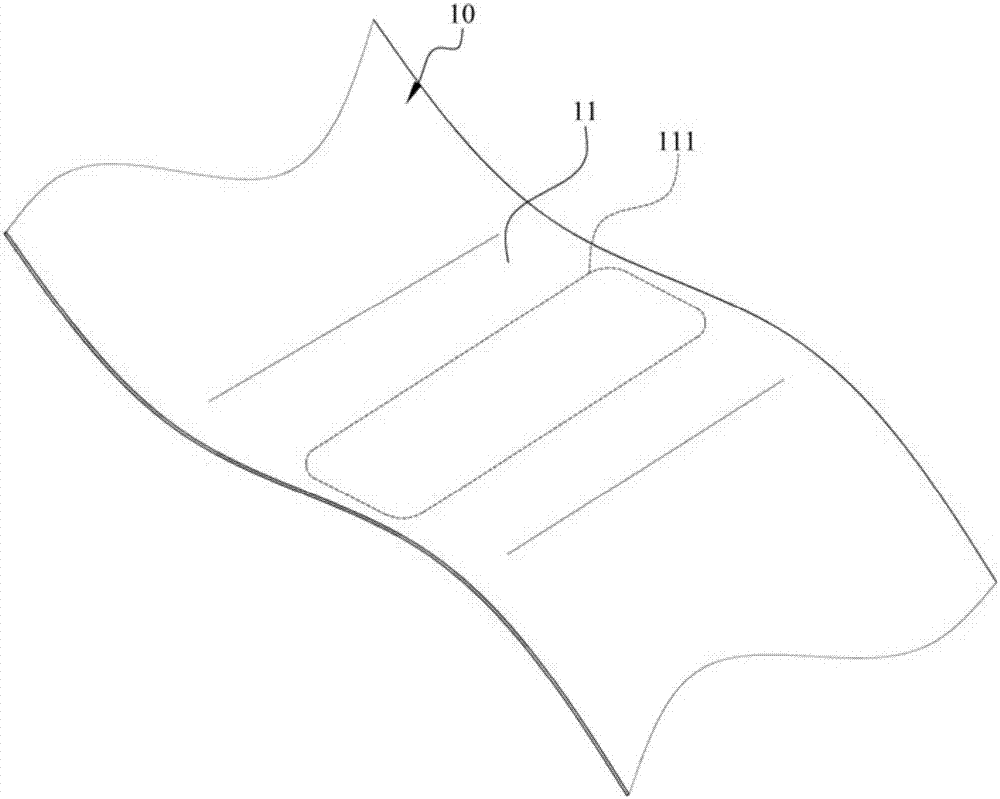

[0049] see figure 1 and figure 2 , and with image 3 and Figure 4 Shown are the method flow chart, the schematic diagram of the manufacturing process, the partial enlarged perspective view of the base material 10 in the thermocompression forming step S4 and the cross-sectional schematic diagram in the thermocompression forming step S4 of the first embodiment of the present invention, which discloses a A manufacturing method for preventing elastic wave deformation, the manufacturing method includes:

[0050] A providing step S1, which provides a substrate 10, the substrate 10 has at least one pre-shaped spring wave forming area 111, the elastic wave forming area 111 is located on the outer surface 11 of the base material 10, wherein the base material 10 It is in the shape of a flexible sheet, and the base material 10 is selected from one or a combination of bamboo fibers, aramid, polyester fibers, cotton fibers, acrylic fibers, silk fibers or polyvinyl naphthene fibers. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com