Surface acoustic wave sensor with low loss and high temperature stability

A surface acoustic wave, high temperature technology, applied in the measurement of the property force of piezoelectric devices, the use of sonic/ultrasonic/infrasonic waves to analyze fluids, etc., can solve the problems of low electrical coupling coefficient and poor temperature stability, and achieve high temperature Stability, high electromechanical coupling coefficient, effect of improving sensor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The novel low-loss and high-temperature-stability surface acoustic wave sensor of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

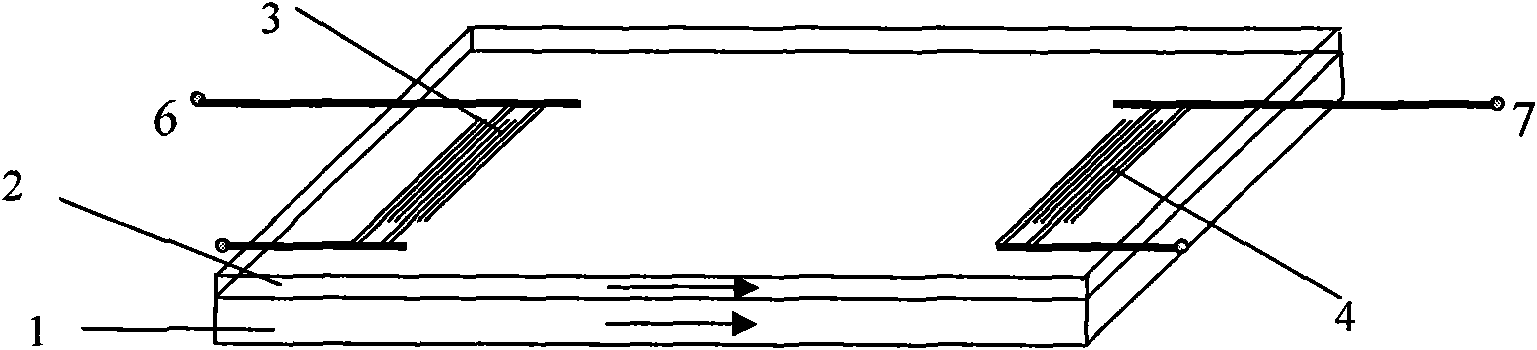

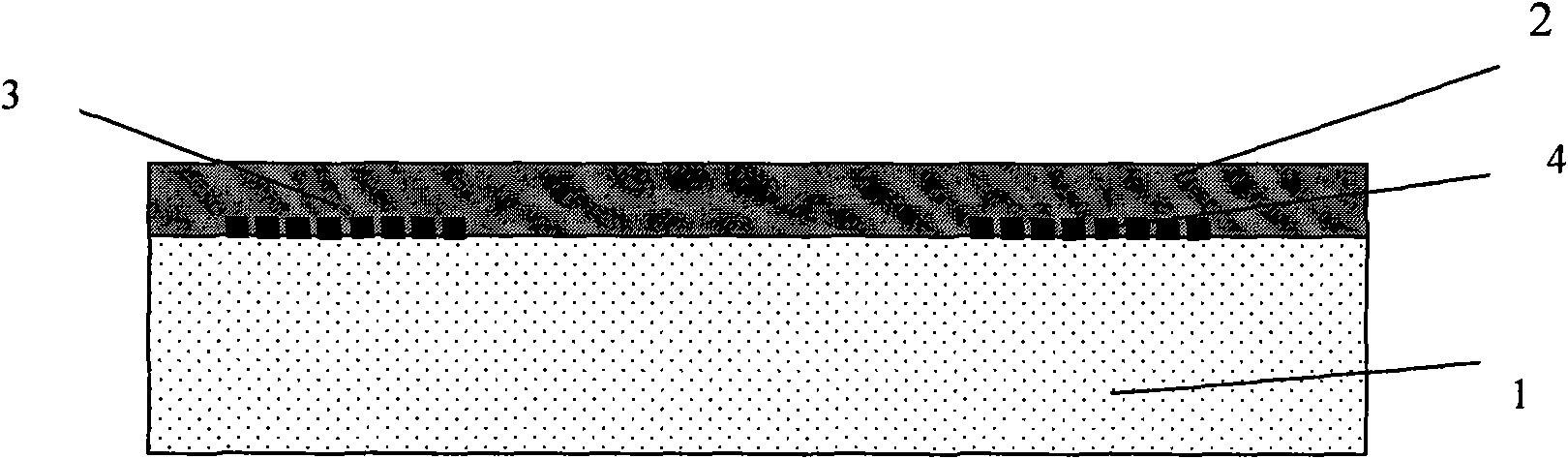

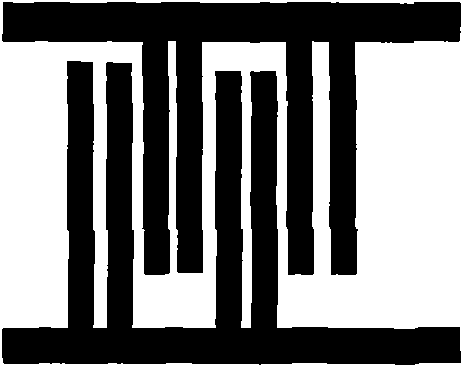

[0023] figure 1 It is a top view of an embodiment of the novel surface acoustic wave sensor with low loss and high temperature stability of the present invention, figure 2 It is a novel surface acoustic wave sensor with low loss and high temperature stability of the present invention figure 1 A cross-sectional view of the embodiment shown. Such as figure 1 as well as figure 2 As shown, the novel surface acoustic wave sensor with low loss and high temperature stability of the present invention includes: a piezoelectric substrate 1, an input IDT 3 and an output IDT deposited on the surface of the piezoelectric substrate 1 4. And the sensitive film 2 covered on the substrate 1, wherein the sensitive film 2 is a nano-structured sensitive material layer, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com