Softening method for producing ferroelectric and ferromagnetic composite material powder by home position

A composite material and in-situ preparation technology, which is applied in the field of soft chemical method to prepare ferrite/ferroelectric composite materials with magnetoelectric effect, and achieves the effect of simple and easy process, high purity and fine powder particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

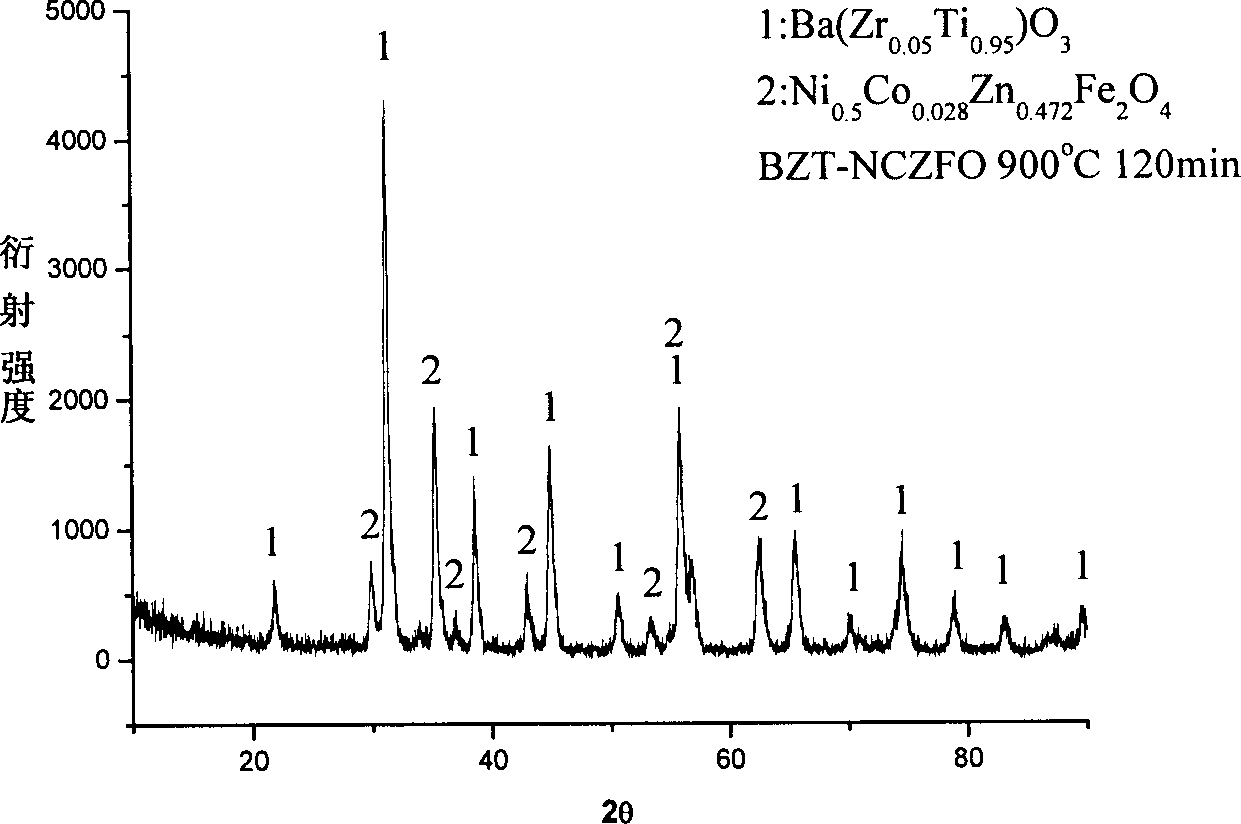

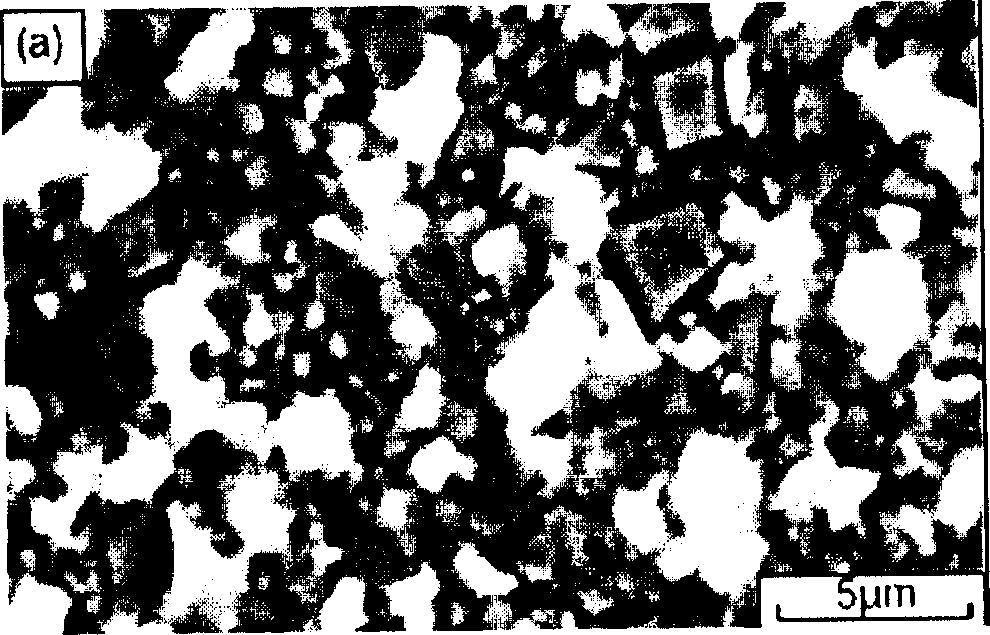

[0016] Example 1: 0.5Ni 0.5 Co 0.028 Zn 0.472 Fe 2 O 4 -0.5Ba(Zr 0.05 Ti 0.95 )O 3 Powder preparation

[0017] Add 0.0125mol of nickel nitrate, 0.0007mol of cobalt nitrate, 0.0118mol of zinc nitrate, 0.025mol of barium nitrate, and 0.00125mol of zirconium nitrate to 150g of deionized water, then add 0.255mol of citric acid, and heat and stir in a water bath at 70°C for 2 hours, then slowly Slowly add 0.02375 mol of tetrabutyl titanate, after stirring to form a uniform solution, add ammonia water to adjust the PH=6.5, and continue to stir for 8 hours to form a stable and uniform sol. Dry the prepared sol in a drying oven at 150°C, and bake it in a drying oven at 250°C after the moisture is completely volatilized until it burns. After burning, the powder is sintered in a muffle furnace at 900°C for 1.5 hours to obtain the desired Powder.

[0018] Because the total molar amount of nitrate is greater than 5 times the molar amount of metal alkoxide, the molar amount of citric acid is t...

Embodiment 2

[0019] Example 2: 0.2Ni 0.5 Co 0.028 Zn 0.472 Fe 2 O 4 -0.8Ba(Zr 0.05 Ti 0.95 )O 3 Powder preparation

[0020] Add 0.19mol citric acid to 150g deionized water, then add 0.005mol nickel nitrate, 0.00028mol cobalt nitrate, 0.00472mol zinc nitrate, 0.04mol barium nitrate, 0.002mol zirconium nitrate, heat and stir in a water bath at 75℃ for 2 hours, then slowly Slowly add 0.038 mol of tetrabutyl orthotitanate, and after stirring to form a uniform solution, add ammonia to adjust the PH=7, and continue to stir for 7 hours to form a stable and uniform sol. Dry the prepared sol in a drying oven at 140°C, and bake it in a drying oven at 260°C after the moisture is completely volatilized until it burns. After burning, the powder is sintered in a muffle furnace at 850°C for 2 hours to obtain the desired Powder.

[0021] Because the total molar amount of nitrate is less than 5 times the molar amount of metal alkoxide, the molar amount of citric acid is 5 times the molar amount of metal alkoxi...

Embodiment 3

[0022] Example 3: 0.5Ni 0.2 Cu 0.2 Zn 0.6 Fe 2 O 4 -0.5Ba(Zr 0.05 Ti 0.95 )O 3 Powder preparation

[0023] Add 0.005mol of nickel nitrate, 0.005mol of copper nitrate, 0.015mol of zinc nitrate, 0.025mol of barium nitrate, and 0.00125mol of zirconium nitrate to 150g of deionized water, then add 0.255mol of citric acid, heat and stir in a water bath at 80°C for 2 hours, and then slowly Slowly add 0.02375 mol of tetrabutyl orthotitanate, after stirring to form a uniform solution, add ammonia water to adjust the PH=6.5, and continue to stir for 8 hours to form a stable and uniform sol. Dry the prepared sol in a drying oven at 130°C, and bake it in a drying oven at 250°C after the moisture is completely volatilized until it burns. After burning, the powder is sintered in a muffle furnace at 900°C for 2 hours to obtain the desired Powder.

[0024] Because the total molar amount of nitrate is greater than 5 times the molar amount of metal alkoxide, the molar amount of citric acid is the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com