High-potential lithium ion battery NCM ternary anode material and manufacturing method thereof

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as poor electrochemical cycle performance, and achieve the goal of improving lithium ion conductivity, stability, and processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

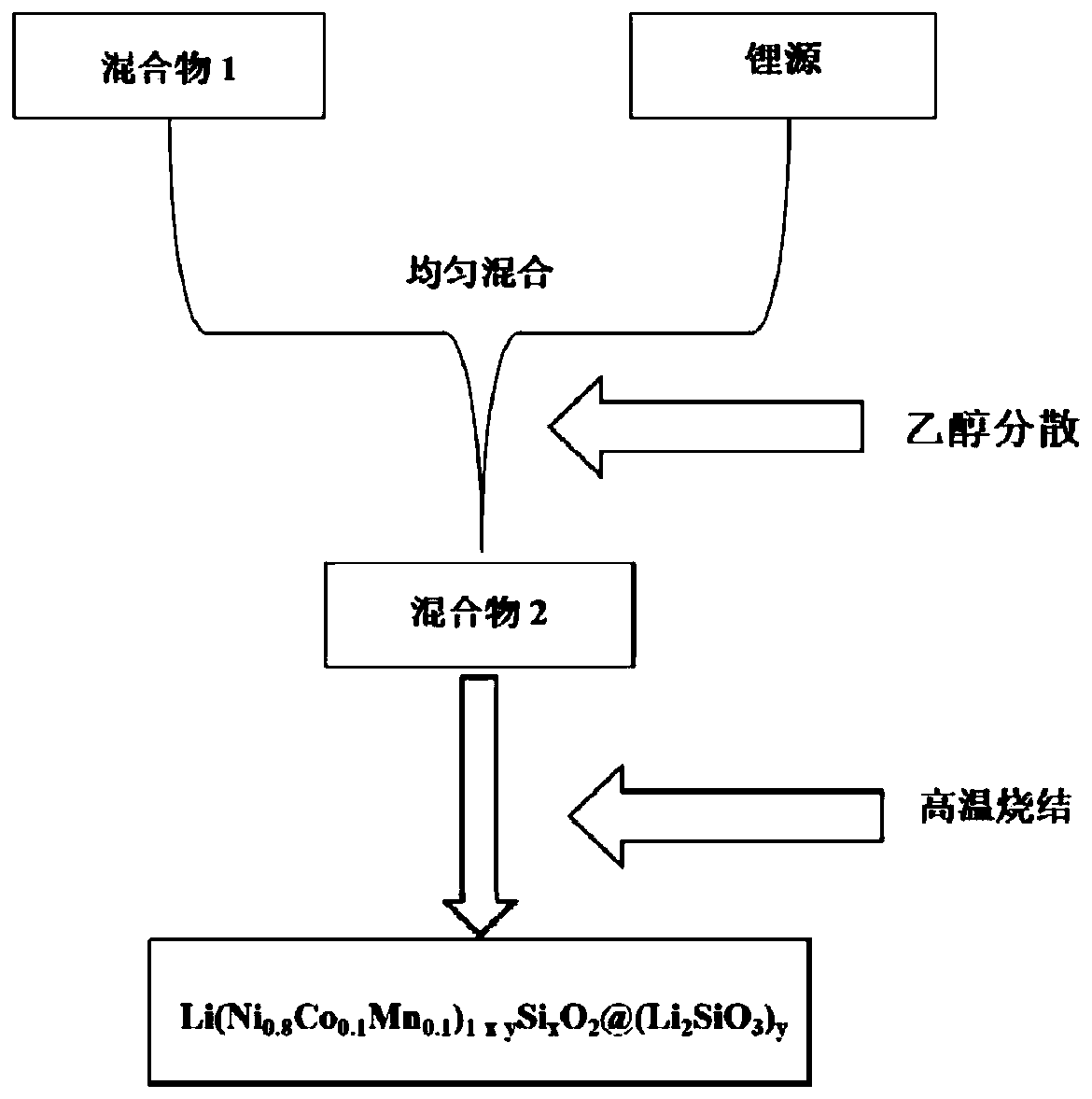

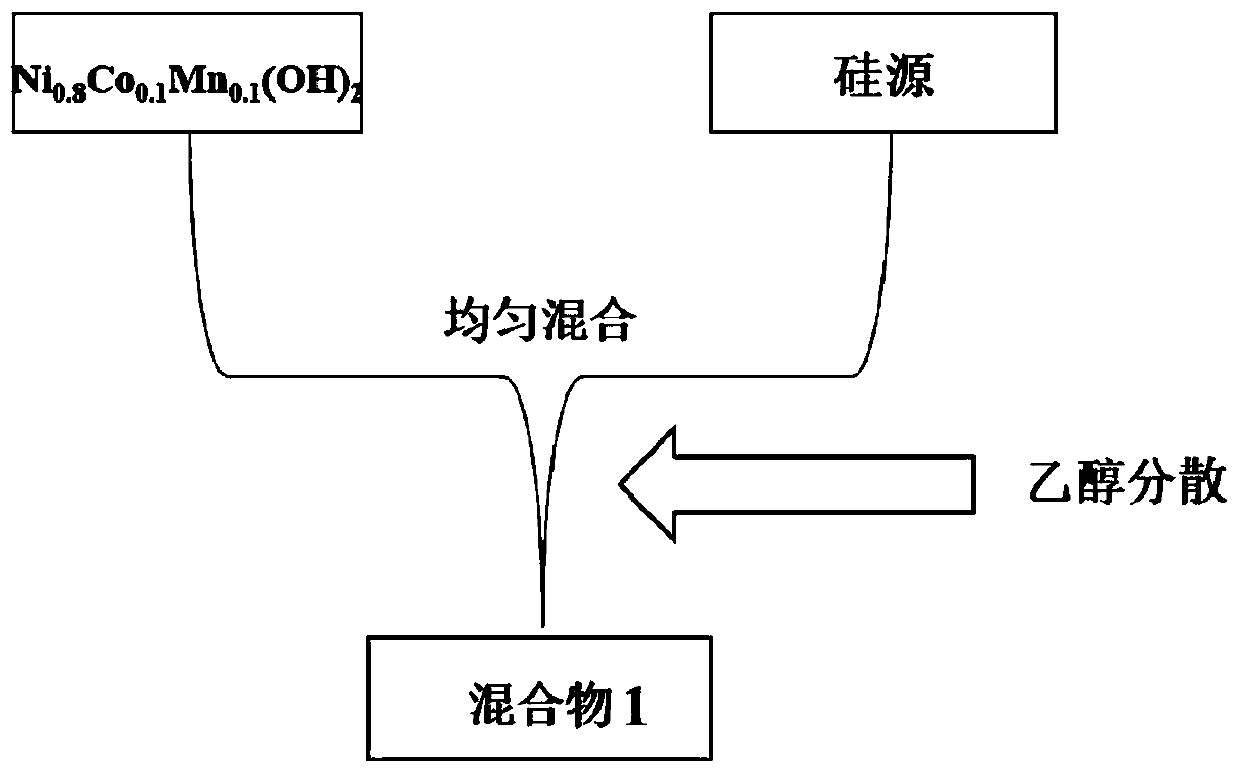

[0029] When the total doping amount of Si is 0.01, that is, x+y=0.01; by weighing 2.7324g precursor, 0.018g nano-SiO 2 And mix evenly, use alcohol as a dispersant, fully grind evenly, then put it in an oven to dry and grind to obtain a mixture 1 (such as figure 2 shown); with alcohol as a dispersant, weigh 1.34g lithium hydroxide monohydrate (LiOH·H 2 O) and fully grind the mixture 1 obtained before to obtain the mixture 2; finally put the dried mixture 2 into the tube furnace under an oxygen atmosphere (oxygen flow rate 400ml / min) and heat up to 480°C at a speed of 3°C / min Pre-fire for 6 hours, then heat up to 780°C for 15 hours at a rate of 2°C / min, then cool down to room temperature naturally, take out the material and grind it finely and sieve it to obtain the lithium ion positive electrode material (such as figure 1 shown).

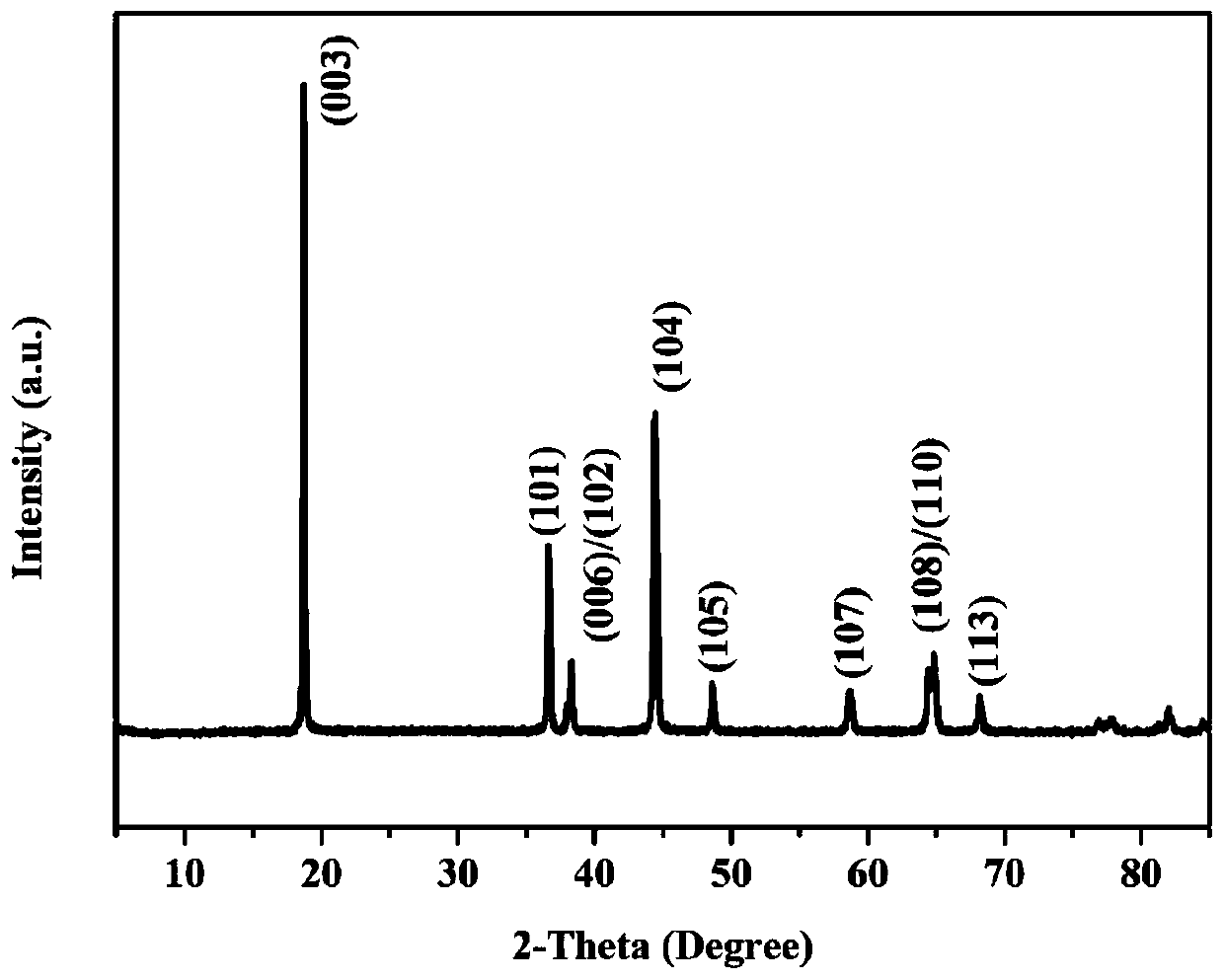

[0030] Carry out XRD test to above-mentioned lithium ion cathode material, its result is as follows image 3 As shown; the material presents a p...

Embodiment 2

[0034] When the total doping amount of Si is 0.02, that is, x+y=0.02, take 2.7048g precursor and 0.036g nano-SiO 2 And mix evenly, use alcohol as a dispersant, fully grind evenly, then put it in an oven to dry and grind to obtain a mixture 1; use alcohol as a dispersant, and then weigh 1.36g lithium hydroxide monohydrate (LiOH·H 2 O) and fully grind the mixture 1 obtained before to obtain the mixture 2; finally put the dried mixture 2 into the tube furnace under an oxygen atmosphere (oxygen flow rate 400ml / min) and heat up to 500°C at a speed of 3°C / min Pre-fired for 6 hours, then heated up to 800°C at a rate of 2°C / min and baked for 15 hours, then cooled down to room temperature naturally, and the material was taken out and ground and sieved to obtain the lithium ion cathode material.

[0035] The constant current charge and discharge test was carried out on the above-mentioned lithium ion positive electrode material. From the test results, it can be seen that the positive el...

Embodiment 3

[0037] When the total doping amount of Si is 0.02, that is, x+y=0.02, weigh 2.7048g of the precursor, then weigh a proportional amount of tetraethyl orthosilicate, add it to an appropriate amount of absolute ethanol and mix it evenly, and add it to the precursor , using alcohol as a dispersant, fully ground evenly, then put it in an oven to dry and grind to obtain a mixture 1; using alcohol as a dispersant, weigh 1.36g of lithium hydroxide monohydrate (LiOH·H 2 O) and fully grind the mixture 1 obtained before to obtain the mixture 2; finally put the dried mixture 2 into the tube furnace under an oxygen atmosphere (oxygen flow rate 400ml / min) and heat up to 480°C at a speed of 3°C / min Pre-fire for 8 hours, then heat up to 800°C at a rate of 2°C / min and bake for 15 hours, then cool down to room temperature naturally, take out the material, grind it and sieve it to obtain the lithium ion cathode material.

[0038]The constant current charge and discharge test was carried out on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com