Calcium cobaltate-based oxide thermoelectric material and its prepn.

A technology of thermoelectric materials and oxides, applied in cobalt compounds, chemical instruments and methods, circuits, etc., can solve the problems of high reaction temperature, high energy consumption, long reaction time, etc., and achieve good chemical uniformity, low reaction temperature, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

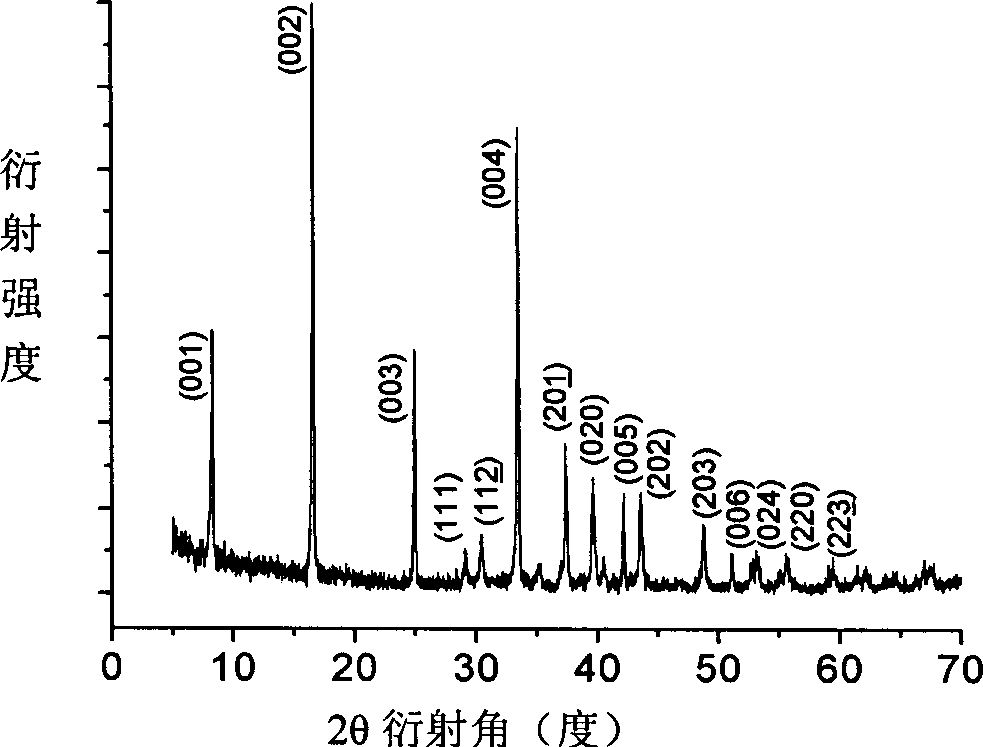

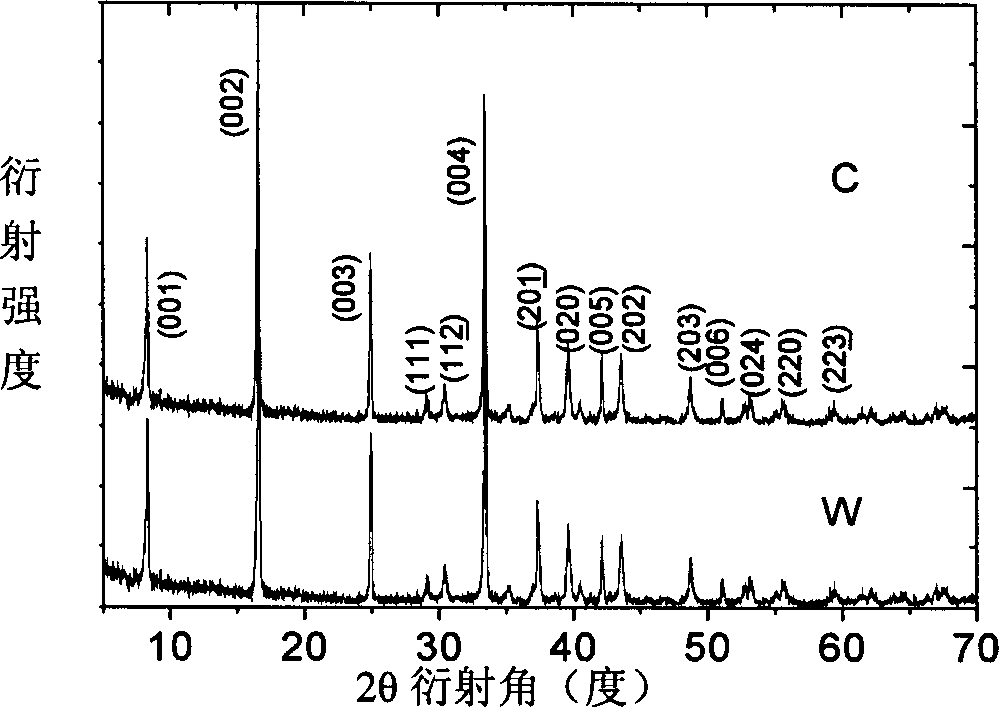

[0036] Example 1. Ca 3 co 4 o 9

[0037] Ca(NO 3 ) 2 4H 2 O(30mmol), Co(NO 3 ) 2 ·6H 2 O (40mmol), C 6 h 8 o 7 ·H 2O (105 mmol) was added into the beaker, and then the mixture was dissolved with deionized water and stirred until a transparent solution; the temperature was raised to 60° C. until the solution became a sol. It was then dried at 100°C for 12 hours. After the dry gel is ground, it is pre-fired at 400°C to remove citric acid and nitrate. The resulting powder is sintered at 800°C to obtain a bulk thermoelectric material. For compound characterization see figure 1 with 2 . At 700°C, conductivity σ=10S / cm, Seebeck coefficient S=120μV / K, power factor PF=0.14×10 -4 W / mK 2 , ZT=0.13.

Embodiment 2

[0038] Example 2. Ca 3 co 4 o 9

[0039] Ca(NO 3 ) 2 4H 2 O(30mmol), Co(NO 3 ) 2 ·6H 2 O (40mmol), C 6 h 8 o 7 ·H 2 O (91 mmol) was added to the beaker, then the mixture was dissolved with deionized water and stirred until a clear solution. Raise the temperature to 100°C until the solution becomes a sol. It was then dried at 130°C for 10 hours. After the dry gel is ground, it is pre-fired at 600°C to remove citric acid and nitrate. The resulting powder is sintered at 950°C to obtain a bulk thermoelectric material. At 700°C, conductivity σ=10S / cm, Seebeck coefficient S=120μV / K, power factor PF=0.14×10 -4 W / mK 2 , ZT=0.13.

Embodiment 3

[0040] Example 3. Ca 3 co 4 o 9

[0041] Ca(NO 3 ) 2 4H 2 O(30mmol), Co(NO 3 ) 2 ·6H 2 O (40mmol), C 6 h 8 o 7 ·H 2 O (140 mmol) was added into the beaker, then the mixture was dissolved with deionized water and stirred until a clear solution. Raise the temperature to 80°C until the solution becomes a sol. It was then dried at 110°C for 12 hours. After the dry gel is ground, it is pre-fired at 500°C to remove citric acid and nitrate. The obtained powder is sintered at 850°C to obtain a bulk thermoelectric material. At 700°C, conductivity σ=10S / cm, Seebeck coefficient S=120μV / K, power factor PF=0.14×10 -4 W / mK 2 , ZT=0.13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com