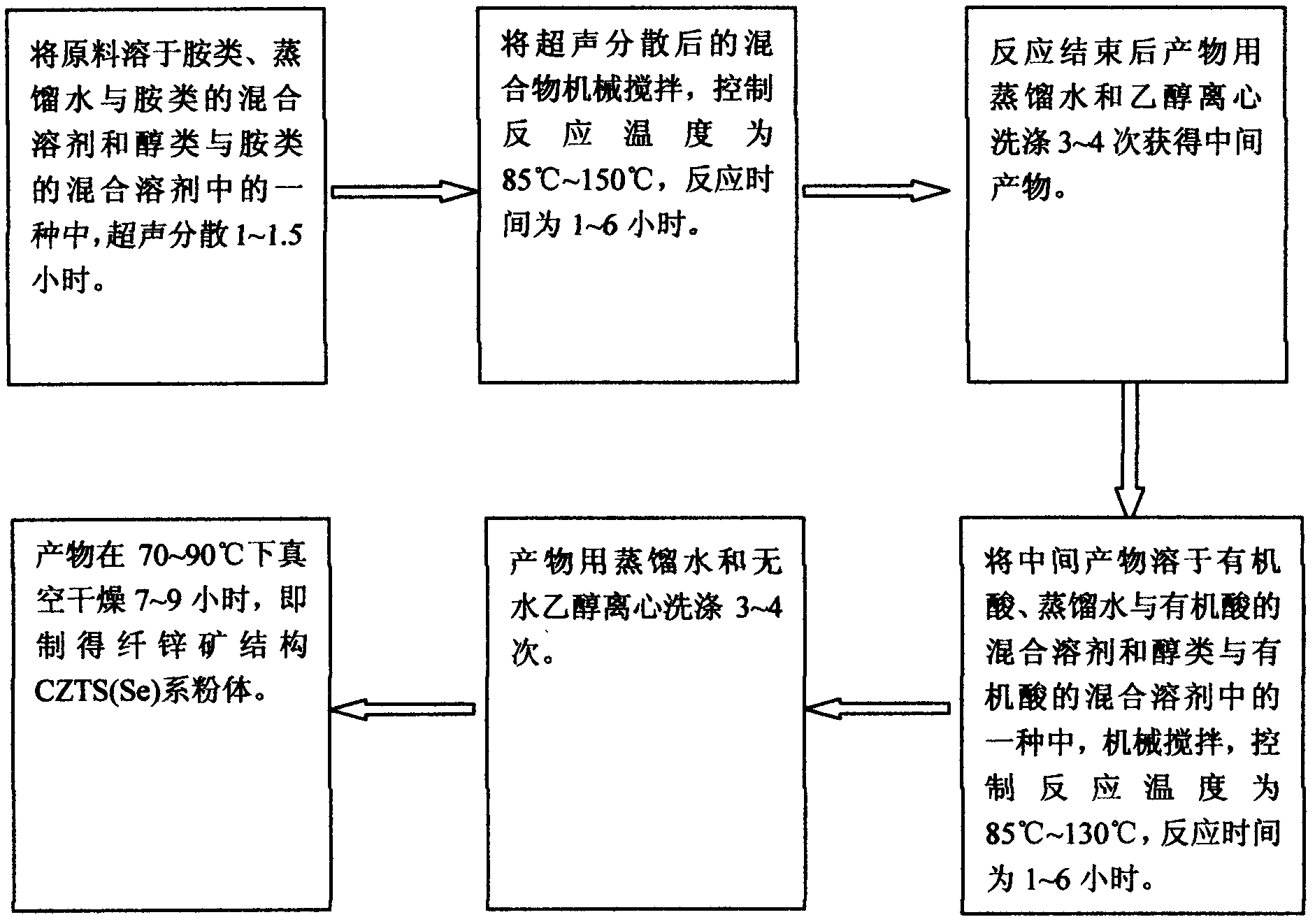

Preparation method of wurtzite structure CZTS (Se) system powder

A wurtzite and powder technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as inability to intervene, high requirements for reaction equipment, and difficulty in controlling the composition of target products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 (Cu 2 ZnSnS 4 ):

[0022] (1) take by weighing 0.64 gram Cu powder respectively according to molar ratio 2: 1: 1: 4, 0.327 gram Zn powder, 0.593 gram Sn powder, 0.64 gram S powder is that raw material is dissolved in 10ml ethanol and 60ml ethylenediamine mixed solvent, After ultrasonic dispersion for 1 hour, stir mechanically, heat to 85°C, and keep warm for 6 hours;

[0023] (2) The product obtained in step (1) is centrifuged and washed 3 times with distilled water and ethanol to obtain an intermediate product;

[0024] (3) Dissolve the intermediate product obtained in step (2) in 10 ml of distilled water and 40 ml of acetic acid mixed solvent, stir mechanically, heat to 85° C., and keep warm for 1 hour;

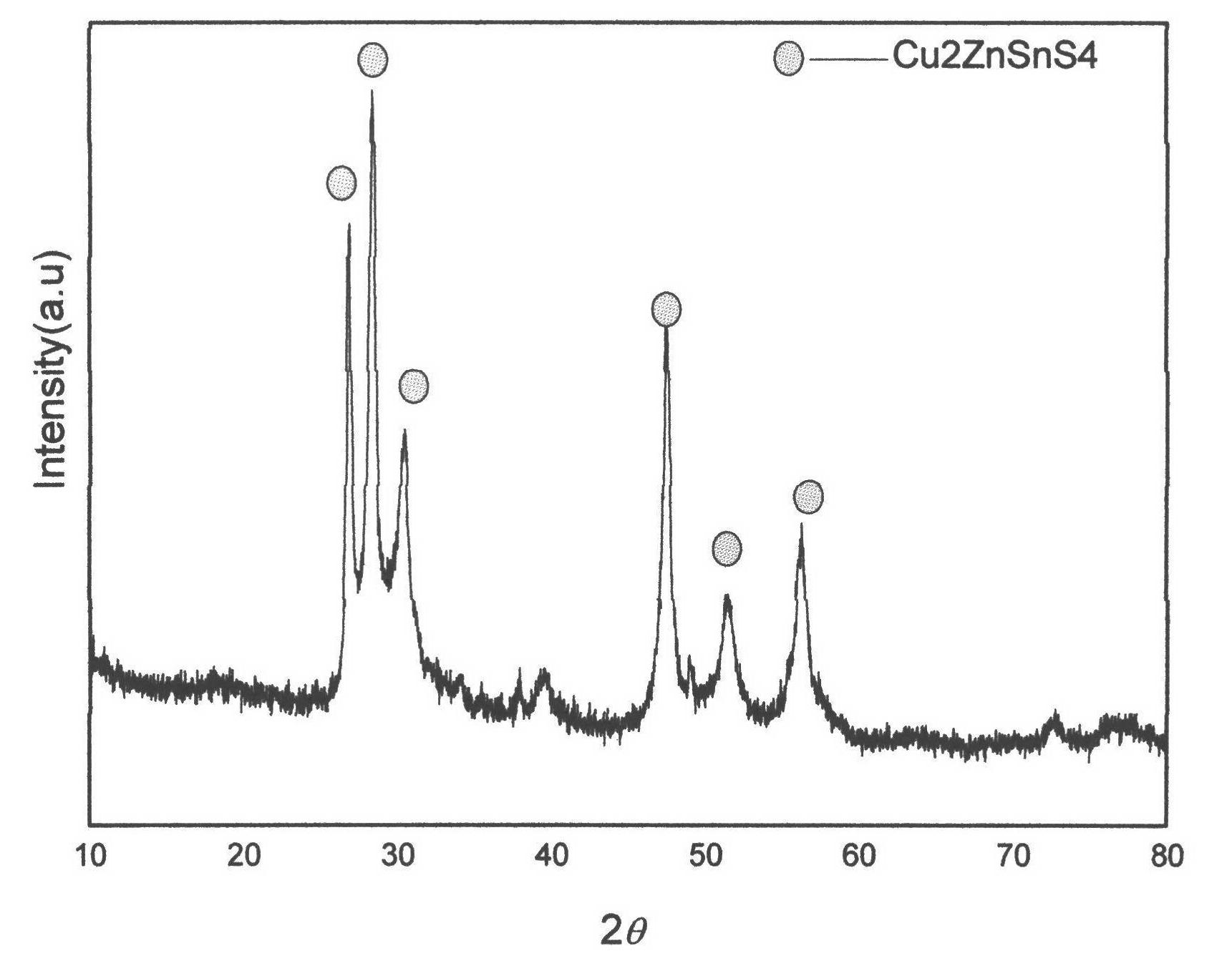

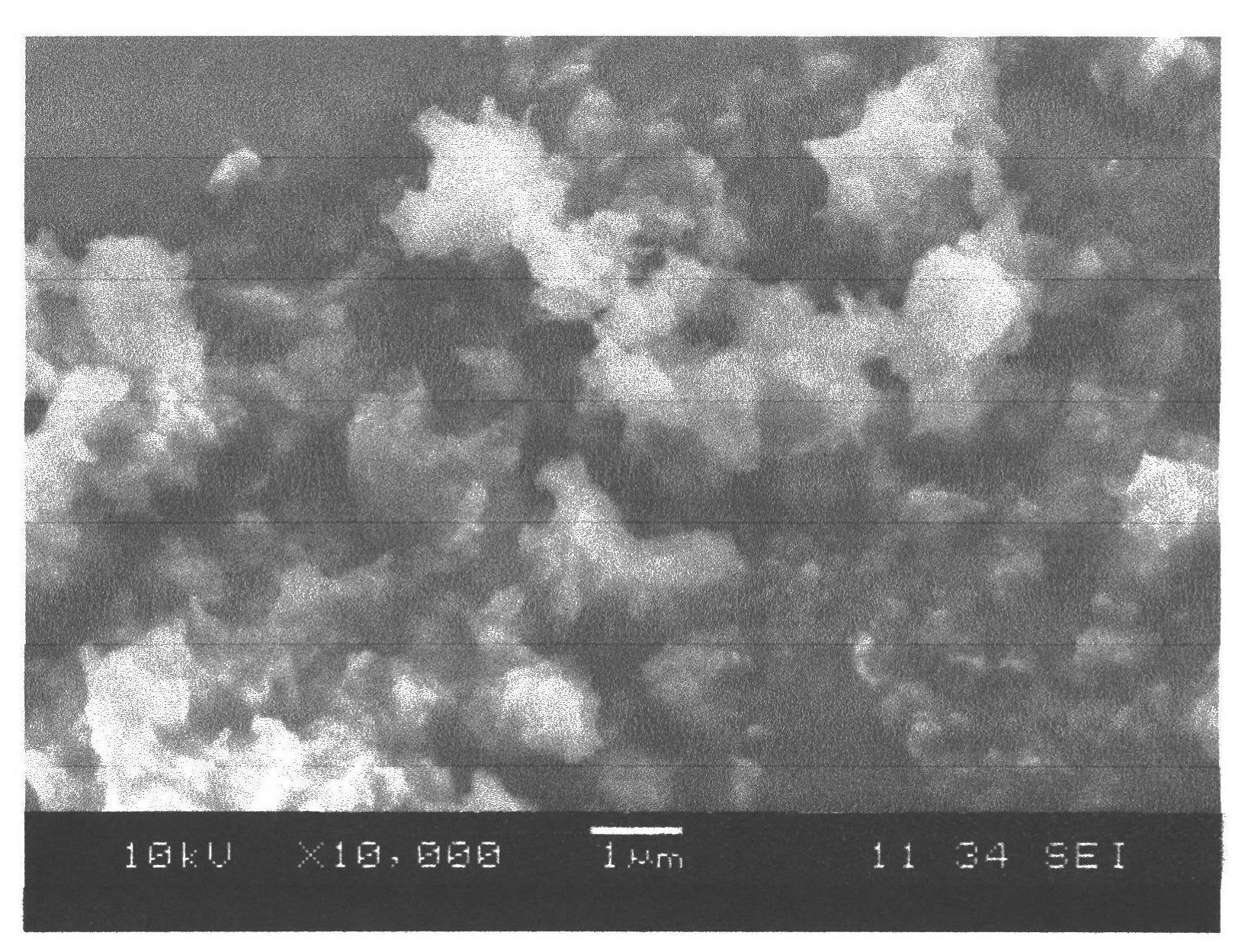

[0025] (4) The product prepared in the step (3) was centrifugally washed with distilled water and ethanol for 3 times, and the product after centrifugal washing was vacuum-dried in a vacuum drying oven at 80° C. for 8 hours. The sample was analyzed b...

Embodiment 2

[0026] Embodiment 2 (Cu 2 ZnSnS 2 Se 2 ):

[0027] (1) Take by weighing 0.64 gram of Cu powder according to the molar ratio of 2: 1: 1: 2: 2, 0.327 gram of Zn powder, 0.593 gram of Sn powder, 0.32 gram of S powder, and 0.789 gram of Se powder as raw materials dissolved in 50 ml of ethylene glycol and In 50ml of ethylenediamine mixed solvent, ultrasonically disperse for 1 hour, then mechanically stir, heat to 150°C, and keep warm for 1 hour;

[0028] (2) The product obtained in step (1) is centrifuged and washed 3 times with distilled water and ethanol to obtain an intermediate product;

[0029] (3) Dissolve the intermediate product obtained in step (2) in a mixed solvent of 50ml ethylene glycol and 50ml acetic acid, stir mechanically, heat to 130°C, and keep warm for 6 hours;

[0030] (4) The product prepared in the step (3) was centrifugally washed with distilled water and ethanol for 3 times, and the product after centrifugal washing was vacuum-dried in a vacuum drying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com