A kind of preparation method of tin-based silver graphene lead-free composite solder

一种复合钎料、银石墨的技术,应用在制造工具、焊接设备、金属加工设备等方向,能够解决金属基体结合强度差、难以均匀分布等问题,达到提高载荷传递、细化晶粒、提高粉末活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, prepare tin-based silver graphene lead-free composite solder, the steps are as follows:

[0025] (1) take by weighing 30mg graphene with electronic balance, 10mg sodium lauryl sulfate, then mix it, measure the dimethylformamide of 40ml with graduated cylinder, mix the SDS (10mg) of 30mg graphene and 10mg Sodium dialkylsulfate) was added to 40ml of DMF (dimethylformamide), and sonicated for 2 hours.

[0026] (2) Measure the silver nitrate solution that 20ml molar concentration is 0.06mol / ml with graduated cylinder again, add the mixed solution that step (1) makes to it, ultrasonic treatment 30 minutes, graphene is obtained better modification, then in After heating at 70°C for 1 hour, filter, wash with water and then with alcohol to obtain silver graphene nanosheets (AG-GNSs).

[0027] (3) Then weigh a certain amount of 96.5Sn-3.0Ag-0.5Cu alloy powder and mix it with silver graphene nano-silver sheets (AG-GNSs) prepared in step (2) (using 96.5Sn-3.0Ag-0.5C...

Embodiment 2

[0032] Embodiment 2, preparation tin-based silver graphene lead-free composite solder, step is basically the same as embodiment 1, and its difference is only in:

[0033] Step 3: when mixing 96.5Sn-3.0Ag-0.5Cu alloy powder with silver graphene nano-silver sheets (AG-GNSs), the mass fraction of silver-graphene nano-sheets in the mixed powder is 0.05%.

Embodiment 3

[0034] Embodiment 3, preparation tin-based silver graphene lead-free composite solder, step is basically the same as embodiment 1, and its difference is only in:

[0035] Step 3: when mixing 96.5Sn-3.0Ag-0.5Cu alloy powder with silver graphene nano-silver sheets (AG-GNSs), the mass fraction of silver-graphene nano-sheets in the mixed powder is 0.1%.

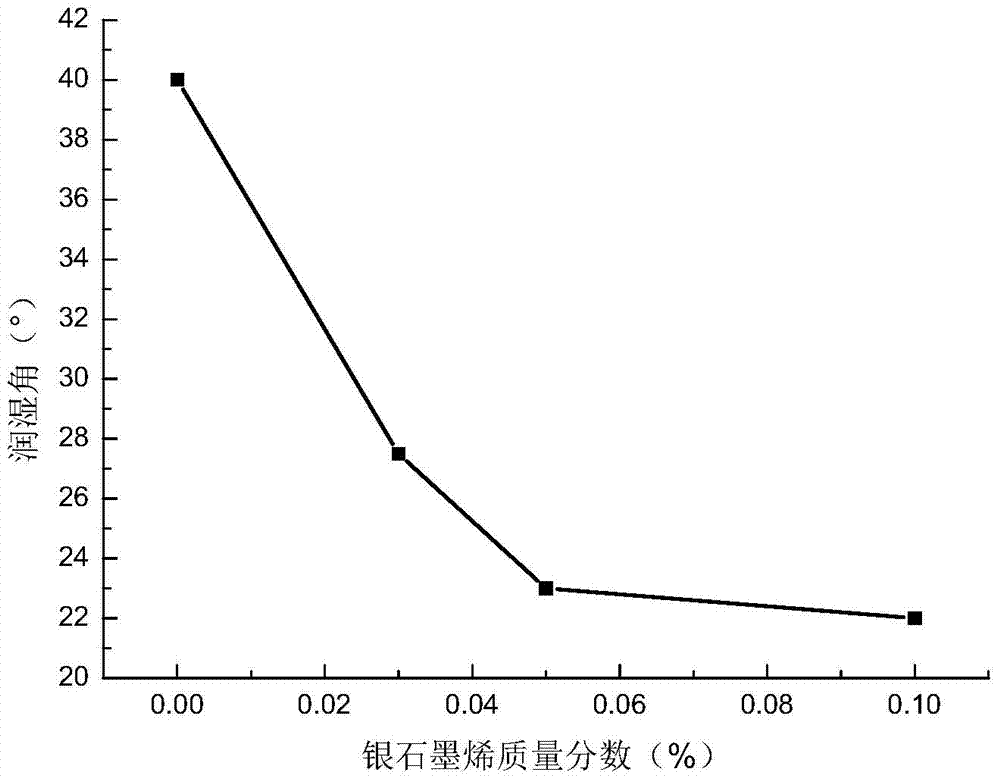

[0036] figure 1 For prior art Sn-Ag-Cu lead-free solder and embodiment 1, embodiment 2, embodiment 3 strengthen the comparative schematic diagram of the wetting angle of lead-free solder by silver graphene nanosheet, by figure 1 It can be seen that with the increase of the mass fraction of silver graphene nanosheets, the wetting angle also gradually decreases, from 40° when no addition to 22° in Example 3.

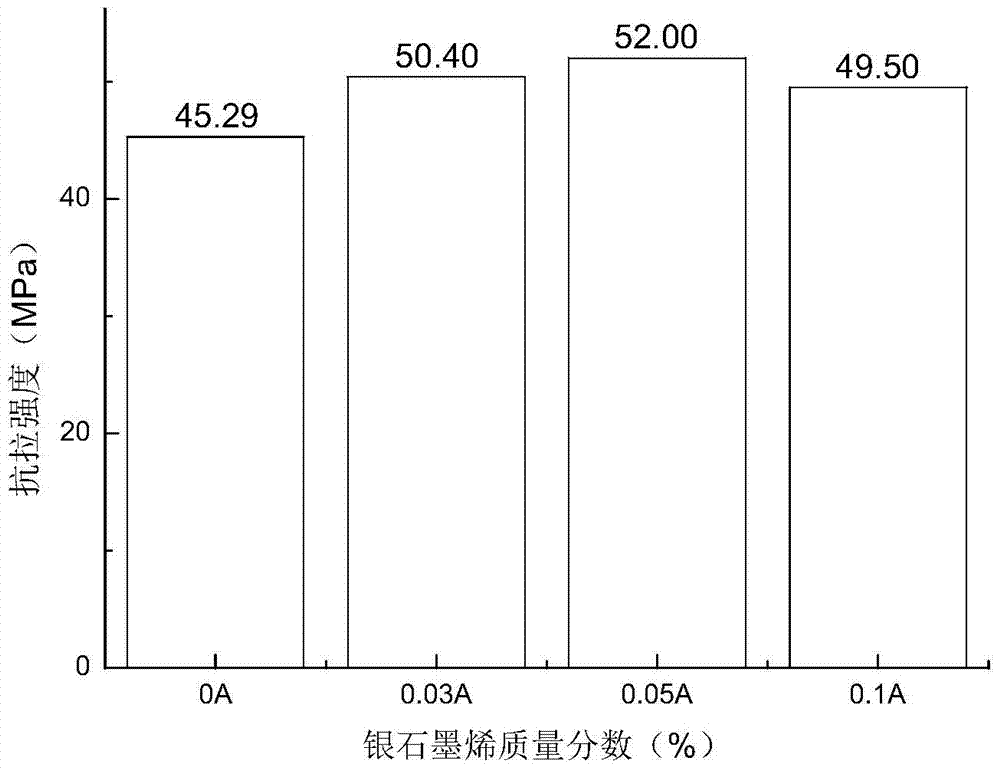

[0037] figure 2 It is a schematic diagram comparing the tensile strength value of the Sn-Ag-Cu lead-free solder of the prior art and the tensile strength value of the lead-free solder enhanced by silver graphene nanosheets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com