Composite zirconia powder for solid oxide fuel cell and preparation method of composite zirconia powder

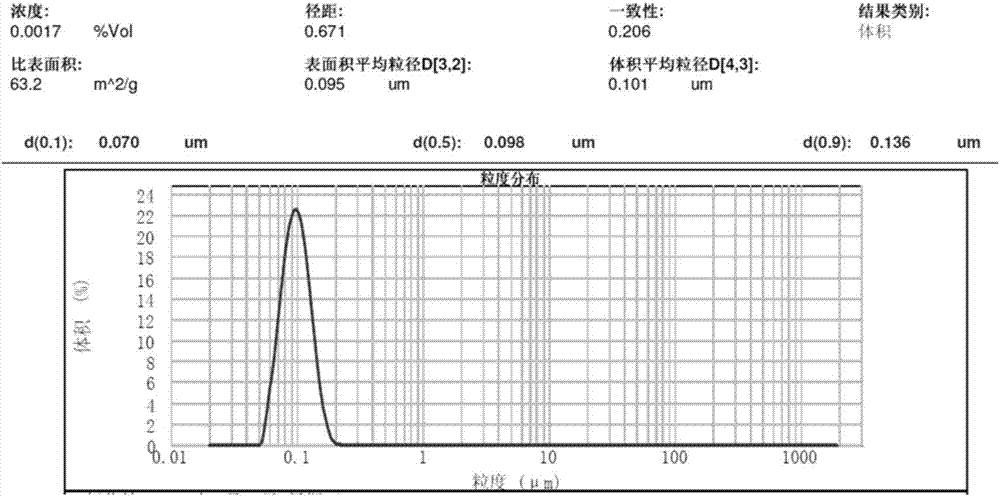

A solid oxide and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as difficult industrial production, agglomeration of zirconia powder, strong mechanical properties, etc., and achieve high powder activity, less agglomeration, The effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method for composite zirconia powder for solid oxide fuel cells, comprising the steps of:

[0022] Step 1, preparing zirconium oxychloride aqueous solution with zirconium oxychloride concentration of 0.5-1.5mol / L, heating to 70°C; 2 o 3 , Y 2 o 3 Dissolve in zirconium oxychloride aqueous solution heated to 70°C, Sc 2 o 3 The content is 1-7mol%, Y 2 o 3 The content is 1-7mol%;

[0023] Step 2, add composite oxide additive and PEG dispersant in step 1 gained solution, described composite oxide additive is made of Al 2 o 3 、TiO 2 , CeO 2 、 Bi 2 o 3 , Li 2 O composition, the mass fraction range of each component of the composite oxide additive in the total system is 0.2-5wt.%, and the mass fraction of the PEG dispersant in the total system is 0.2-0.5wt.%.

[0024] Step 3, add urea to the resultant in step 2 under stirring, the mass fraction of urea in the total system is 5-10wt.%, and then slowly add ammonia water to adjust the pH value of the sy...

Embodiment 1

[0032] A method for preparing composite zirconia powder for solid oxide fuel cells, the specific steps of which are:

[0033] (1) Weigh zirconium oxychloride and add deionized water to prepare an aqueous solution with a concentration of 1mol / L, heat to 70°C, and 2 o 3 , Y 2 o 3 Dissolved in zirconium oxychloride solution, the Sc 2 o 3 The content is 3mol%, the Y 2 o 3 The content is 7mol%, add composite oxide additive, composite oxide additive consists of Al 2 o 3 、TiO 2 , CeO 2 、 Bi 2 o 3 , Li 2 O composition, the mass fraction of the total system is 4wt.%, where Al 2 o 3 The addition amount is 1.5wt.%, TiO 2 The addition amount is 0.5wt.%, CeO 2 The addition amount is 0.5wt.%, Bi 2 o 3 The addition amount is 1wt.%, Li 2 O addition is 0.5wt.%, adding 0.2wt.% PEG dispersant;

[0034] (2) Slowly add urea under stirring, the mass fraction of urea in the total system is 5wt.%, slowly add ammonia water, hydrolyze and precipitate, and adjust the pH value of the ...

Embodiment 2

[0040] A method for preparing composite zirconia powder for solid oxide fuel cells, the specific steps of which are:

[0041] (1) Weigh zirconium oxychloride and add deionized water to prepare an aqueous solution with a concentration of 1mol / L, heat to 70°C, and 2 o 3 , Y 2 o 3 Dissolved in zirconium oxychloride solution, the Sc 2 o 3 The content is 5mol%, the Y 2 o 3 The content is 5mol%, add composite oxide additive, composite oxide additive consists of Al 2 o 3 、TiO 2 , CeO 2 、 Bi 2 o 3 , Li 2 O composition, the mass fraction of the total system is 5wt.%, where Al 2 o 3 The addition amount is 2wt.%, TiO 2 The addition amount is 1wt.%, CeO 2 The addition amount is 0.5wt.%, Bi 2 o 3 The addition amount is 0.5wt.%, Li 2 The amount of O added is 1wt.%, and 0.3wt.% of PEG dispersant is added;

[0042] (2) Slowly add urea under stirring, the mass fraction of urea in the total system is 7wt.%, slowly add ammonia water, hydrolyze and precipitate, and adjust the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Sintered density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com