Nano ceramic-aluminum composite powder and preparation method and device thereof

A technology for preparing aluminum composite materials and powders, which is applied in the field of composite material manufacturing, can solve the problems of difficult wettability between the reinforced phase and the liquid phase metal, poor interface reaction, high manufacturing cost, etc., and achieve reduced reaction activation energy, excellent performance, and operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, see figure 1 :

[0034] The invention provides a nano-ceramic-aluminum composite material powder and a preparation method thereof, comprising the following steps:

[0035] 1) Place a mixture of 5ml of 6061 aluminum alloy powder and 95ml of silicon carbide nanoparticles in a vacuum drying oven, and dry at 100°C for 6h;

[0036] 2) In a glove box filled with argon gas (oxygen content below 1000ppm), put the dried mixture into a ball mill jar, add 1 wt. Type ball mill for high-energy ball milling, the grinding balls are stainless steel balls with a diameter of 20 mm, and the mass ratio of the grinding balls and the mixture is 20:1: firstly, the ball mill is carried out at 200 rpm for 2 hours, so that the mixture of the aluminum alloy powder and ceramic nanoparticles is uniformly mixed, and then Ball milling at 500rpm for 12h;

[0037] 3) In the glove box filled with argon, open the ball mill tank and transfer it to the transition chamber for passivation: vacu...

Embodiment 2

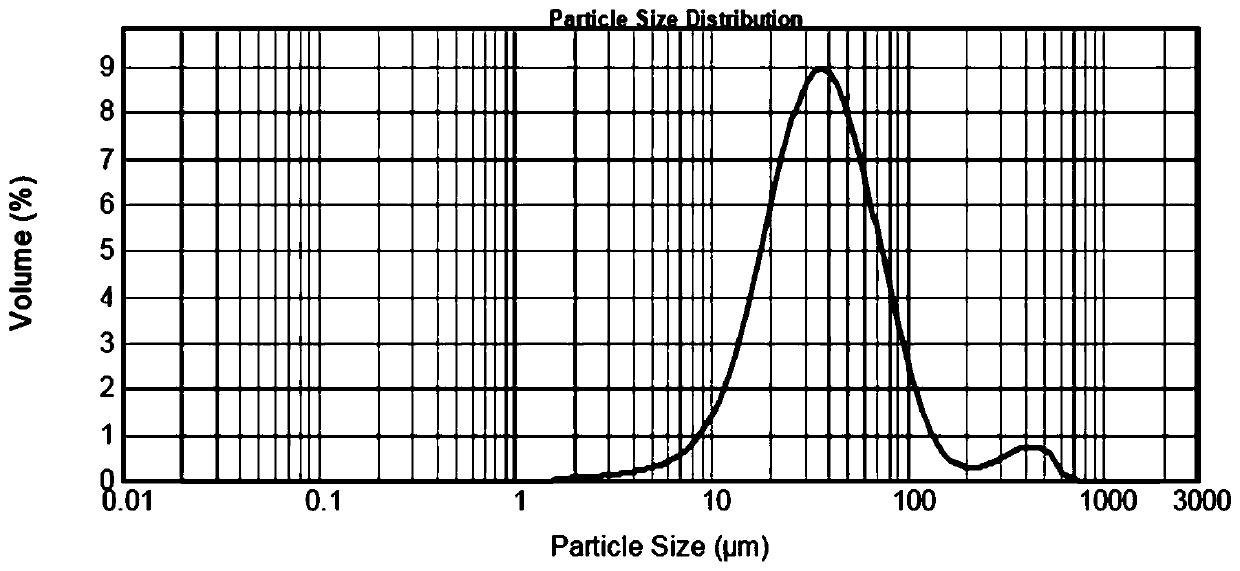

[0039] Example 2, see figure 2 :

[0040] The invention provides a nano-ceramic-aluminum composite material powder and a preparation method thereof, comprising the following steps:

[0041] 1) Place a mixture of 3ml of 7075 aluminum alloy powder and 97ml of silicon carbide nanoparticles in a vacuum drying oven, and dry at 120°C for 3h;

[0042] 2) In a glove box filled with argon gas (oxygen content below 1000ppm), put the dried mixture into a ball mill jar, add 1 wt. Type ball mill for high-energy ball milling, the grinding balls are stainless steel balls with a diameter of 20 mm, and the mass ratio of the grinding balls and the mixture is 20:1: firstly, the ball mill is carried out at 200 rpm for 2 hours, so that the mixture of the aluminum alloy powder and ceramic nanoparticles is uniformly mixed, and then Ball milling at 500rpm for 12h;

[0043] 3) In the glove box filled with argon, open the ball mill tank and transfer it to the transition chamber for passivation: vac...

Embodiment 3

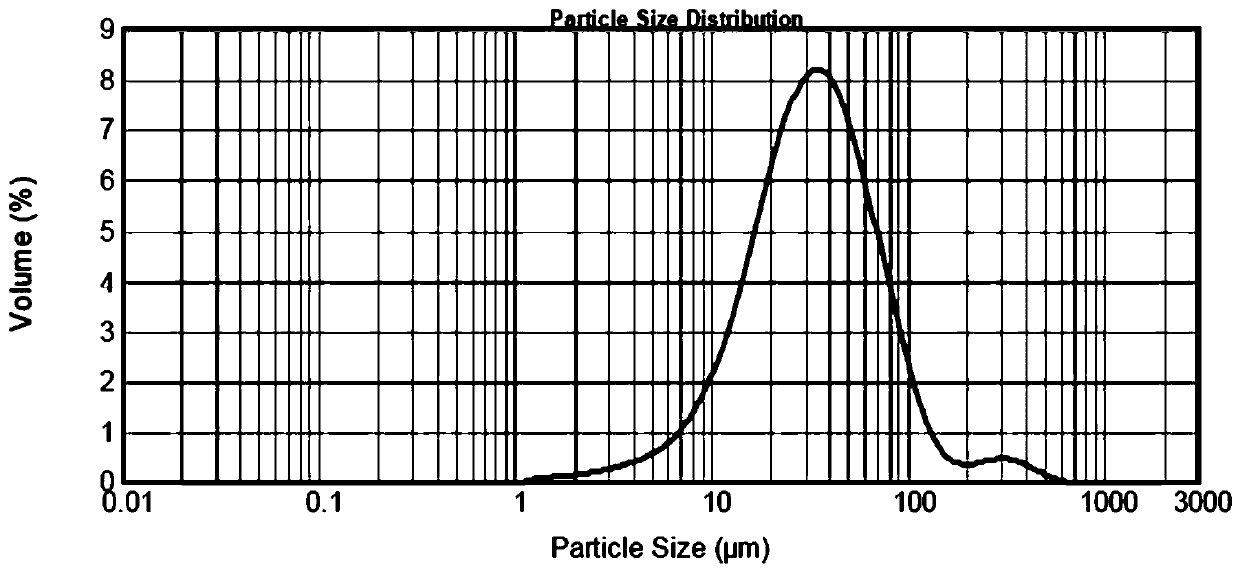

[0045] Example 3, see image 3 :

[0046] The invention provides a nano-ceramic-aluminum composite material powder and a preparation method thereof, comprising the following steps:

[0047] 1) Place a mixture of 8ml of 7075 aluminum alloy powder and 92ml of silicon carbide nanoparticles in a vacuum drying oven, and dry at 80°C for 12h;

[0048] 2) In a glove box filled with argon gas (oxygen content below 1000ppm), put the dried mixture into a ball mill jar, add 1 wt. Type ball mill for high-energy ball milling, the grinding balls are stainless steel balls with a diameter of 20 mm, and the mass ratio of the grinding balls and the mixture is 20:1: firstly, the ball mill is carried out at 200 rpm for 2 hours, so that the mixture of the aluminum alloy powder and ceramic nanoparticles is uniformly mixed, and then Ball milling at 500rpm for 12h;

[0049] 3) In the glove box filled with argon, open the ball mill jar and transfer it to the transition chamber for passivation: vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com