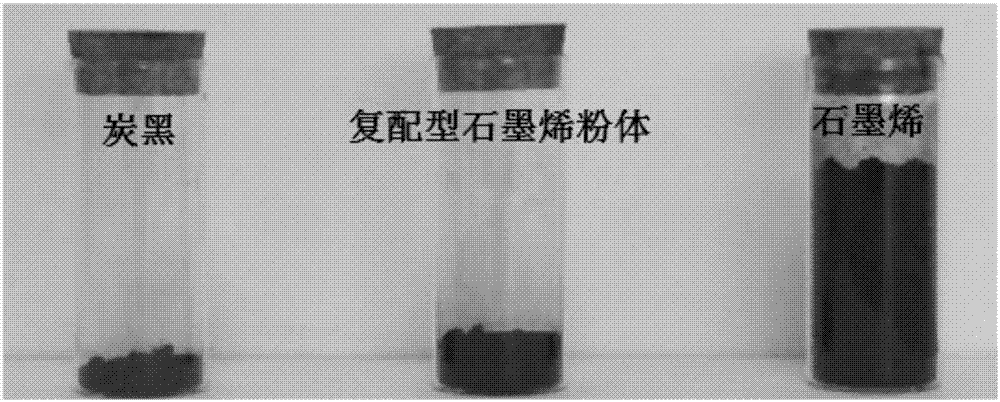

Carbon black and graphene powder composite conductive agent and preparation method and applications thereof

A technology of composite conductive agent and graphene powder, which is applied in the field of electrochemical materials, can solve the problems of side reactions, difficult removal of reducing agent, large amount of conductive agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

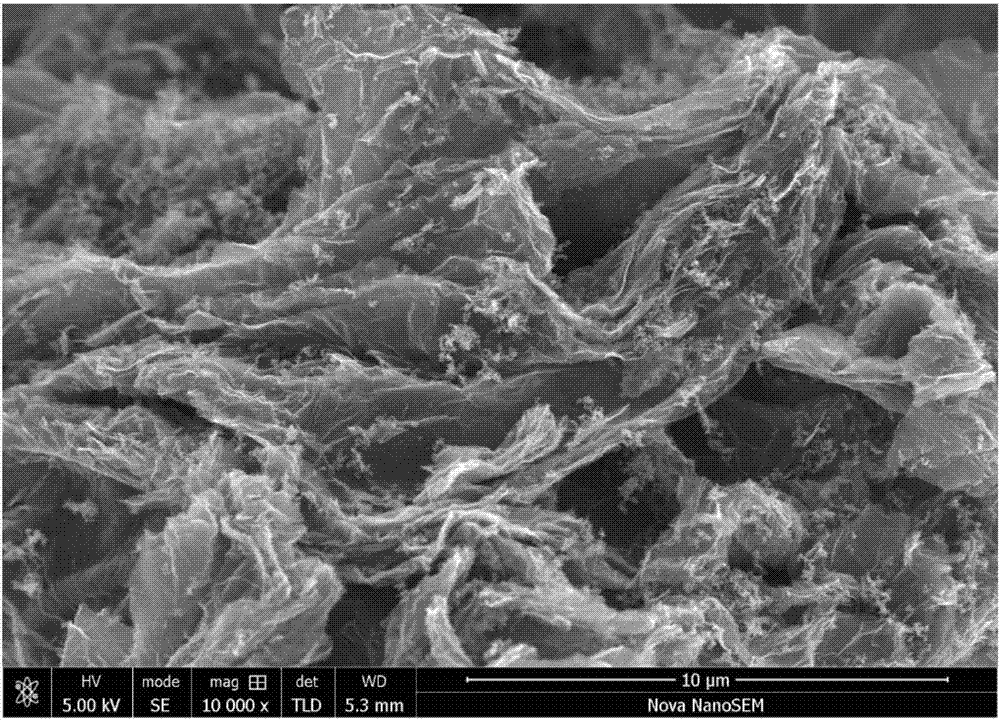

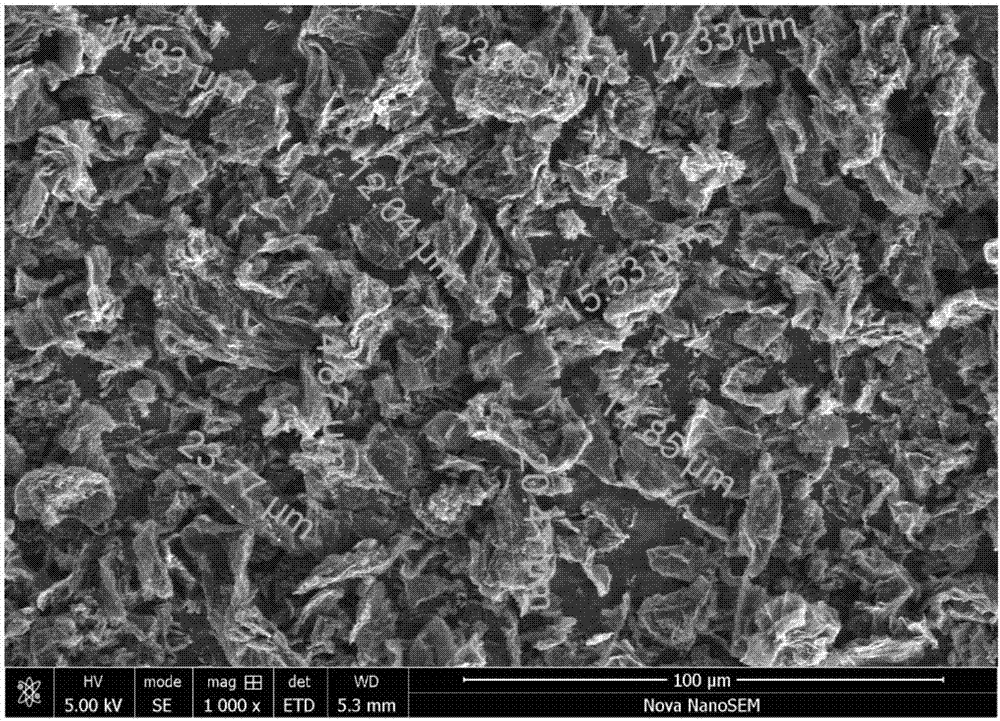

Embodiment 1

[0059] In the ice-water bath, graphite and concentrated sulfuric acid were added to the reaction vessel at a mass ratio of 1:30 under the stirring condition of 150 rpm, and stirred for 20 minutes, and then graphite: potassium permanganate = 1 : Potassium permanganate with a mass ratio of 2 was slowly added to the reaction solution, the temperature of the system was controlled at 15° C., and the entire addition process took about 30 minutes. After adding potassium permanganate, keep the whole reaction system at 30°C for 2 hours, then add graphite: carbon black powder = 5:1 mass ratio of carbon black powder directly into the reaction system, and make the whole reaction system Continue to incubate at 30°C for 2h. Slowly add graphite: water = 1 g: 40 mL of water into the reaction system after the heat preservation is completed, control the temperature in the reaction system to 80° C., and the stirring speed to 200 rpm. After adding water and keeping warm for 60 minutes, add graph...

Embodiment 2

[0061]In an ice-water bath, add graphite:concentrated sulfuric acid=1:30 mass ratio into the reaction vessel under stirring condition of 150rpm, stir and react for 20min, then add graphite:potassium permanganate=1 under stirring condition of 200rpm in ice-water bath : Potassium permanganate with a mass ratio of 2 was slowly added to the reaction solution, the temperature of the system was controlled at 15° C., and the entire addition process took about 30 minutes. After adding potassium permanganate, keep the whole reaction system at 30°C for 2 hours, then add graphite: carbon black powder = 2.5:1 mass ratio of carbon black powder directly into the reaction system, and make the whole reaction system Continue to incubate at 30°C for 2h. Slowly add graphite: water = 1 g: 40 mL of water into the reaction system after the heat preservation is completed, control the temperature in the reaction system to 80° C., and the stirring speed to 200 rpm. After adding water and keeping warm...

Embodiment 3

[0063] In the ice-water bath, under the stirring condition of 150rpm, add graphite and concentrated sulfuric acid into the reaction vessel according to the mass ratio of 1:30, stir and react for 20min, then in the ice-water bath, under the stirring condition of 200rpm, graphite: potassium permanganate = Potassium permanganate with a mass ratio of 1:2 was slowly added to the reaction solution, the temperature of the system was controlled at 15°C, and the entire addition process took about 30 minutes. After adding potassium permanganate, keep the whole reaction system at 30°C for 2 hours, then add graphite: carbon black powder = 20:1 mass ratio of carbon black powder directly into the reaction system, and make the whole reaction system Continue to incubate at 30°C for 2h. Slowly add graphite: water = 1 g: 40 mL of water into the reaction system after the heat preservation is completed, control the temperature in the reaction system to 80° C., and the stirring speed to 200 rpm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com