Preparation method of lithium iron phosphate material anode sheet

A technology of lithium iron phosphate and positive electrode sheet, applied in the field of lithium ion battery preparation, can solve the problems of complex preparation process, unsuitable for large-scale preparation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

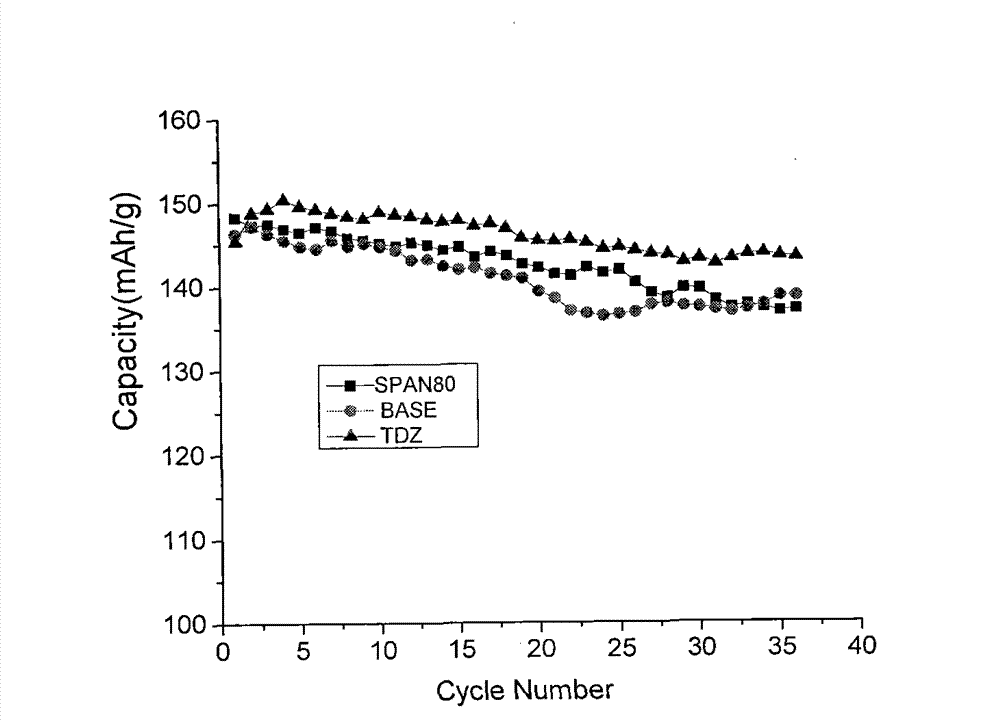

Embodiment 1

[0021] The steps of preparing ultrafine and nanoscale lithium iron phosphate material positive electrode sheet are as follows:

[0022] (1) According to the mass ratio LiFePO4: acetylene black: conductive graphite: PVDF = 90: 2.5: 2.5: 5, accurately weigh 90g of LiFePO4 positive electrode material with an average particle size of about 2-3μm, 2.5g of acetylene black, and 2.5g of conductive graphite and 5g PVDF; 5g PVDF was prepared into 45ml 10% solution with NMP for use.

[0023] (2) First, mix 2.5g of acetylene black and 2.5g of conductive graphite in a dry glass vessel and place them in a 250ml sealed three-necked bottle with stirring, stirring at a speed of 80 rpm, gradually Add 20ml of NMP, continue to stir and disperse for 20 minutes, then add 90g of lithium iron phosphate material in batches, stir for 30 minutes, gradually add 10% PVDF solution, then add 35ml of NMP to make the solid content about 50%, and stop stirring for 30 minutes.

[0024] (3) scrape-coat the slur...

Embodiment 2

[0029] The steps of preparing ultrafine and nanoscale lithium iron phosphate material positive electrode sheet are as follows:

[0030] (1) According to the mass ratio LiFePO4: carbon nanotubes: conductive graphite: PVDF=90:0.2:4.8:5, accurately weigh 90g of LiFePO4 cathode material with a particle size of about 2-3μm, 0.2g of carbon nanotubes, and 4.8g of conductive graphite Graphite and 5g PVDF; 5g PVDF was prepared into 45ml of 10% solution with NMP for use; 0.5g of sorbitan fatty acid ester (SPAN80) was prepared into solution with 5ml of NMP in advance for use.

[0031] (2) First mix the weighed 0.2g carbon nanotubes and 4.8g conductive graphite in a dry glass vessel and place them in a 250ml sealed three-neck flask with stirring, add 25ml NMP solvent, and start the process at 80 rpm After stirring for 20 minutes, add (1) 5ml of SPAN80 NMP solution, continue to stir for 20 minutes, then add 10ml of NMP, stir and disperse for 30 minutes, gradually add 90g of lithium iron ph...

Embodiment 3

[0037] The steps of preparing ultrafine and nanoscale lithium iron phosphate material positive electrode sheet are as follows:

[0038] (1) According to the mass ratio LiFePO4: acetylene black: conductive graphite: PVDF = 90: 1.5: 3.5: 5, accurately weigh 90g of LiFePO4 positive electrode material with a particle size of about 100nm to 200nm, 1.5g of acetylene black, 3.5g of conductive graphite and 5 g of PVDF; 5 g of PVDF was prepared into 45 ml of a 10% solution with NMP for use; 0.1 g of polyacrylonitrile was pre-prepared into a solution with 10 ml of dimethylformamide for use.

[0039] (2) First, mix 1.5g of acetylene black and 3.5g of conductive graphite in a dry glass vessel and place them in a 250ml sealed three-necked flask with stirring, add 10ml of NMP solvent, and use 80 rpm Stir at high speed, stir for 20 minutes, add 10ml polyacrylonitrile dimethylformamide solution, continue stirring for 20 minutes, then add 10ml NMP, stir and disperse for 30 minutes, gradually a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com