Anode material for lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large irreversible capacity loss, no good solution, unstable structure, etc., and achieve excellent electrochemical performance and lattice parameters. The effect of small change and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

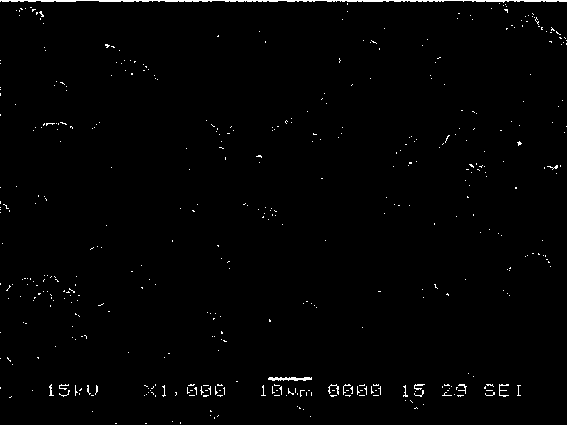

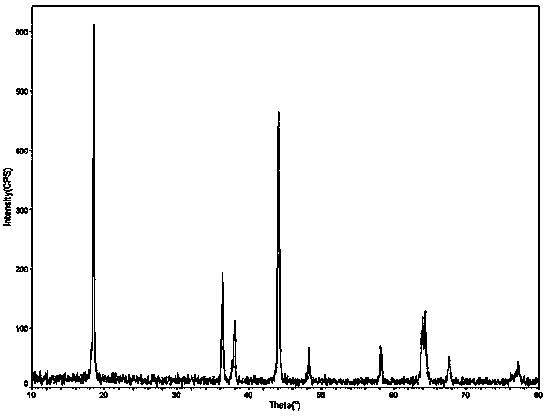

Image

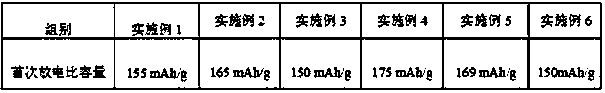

Examples

Embodiment 1

[0029] The present embodiment provides lithium ion battery cathode material, and it has layered structure, and its expression is Li 1.02 Ni 0.6 mn 0.35 Al 0.05 o 2 , Li 1.02 Ni 0.6 mn 0.35 Al 0.05 o 2 The surface is also coated with Al 2 o 3 , Al 2 o 3 Accounting for 1wt% of the total mass of the positive electrode material.

[0030] The preparation method of the cathode material comprises the following steps:

[0031] The first step, select nickel sulfate as nickel salt, manganese sulfate as manganese salt, fully dissolve nickel sulfate and manganese sulfate into deionized water and mix evenly, make the molar ratio of nickel to manganese be 60:35, add ammonium hydroxide to make nickel sulfate Precipitating with manganese sulfate to obtain a precipitate, separating the precipitate, drying and calcining to obtain a manganese-nickel precursor salt.

[0032] In the second step, the nickel-manganese precursor salt is mixed with lithium hydroxide and aluminum acetate ...

Embodiment 2

[0036] The present embodiment provides lithium ion battery cathode material, and it has layered structure, and its expression is Li 1.03 Ni 0.7 mn 0.26 Mg 0.04 o 2 , Li 1.03 Ni 0.7 mn 0.26 Mg 0.04 o 2 The surface of is also coated with MgO, and MgO accounts for 2wt% of the total mass of the positive electrode material.

[0037] The preparation method of the cathode material comprises the following steps:

[0038] The first step, select nickel nitrate as nickel salt, manganese nitrate as manganese salt, fully dissolve nickel nitrate and nickel nitrate into deionized water and mix evenly, make the molar ratio of nickel to manganese be 70:26, add lithium hydroxide to make nickel nitrate Precipitating with nickel nitrate to obtain a precipitate, separating the precipitate, drying and calcining to obtain a manganese-nickel precursor salt.

[0039] In the second step, the nickel-manganese precursor salt is mixed with lithium carbonate and magnesium sulfate by ball milling,...

Embodiment 3

[0042] The present embodiment provides lithium ion battery cathode material, and it has layered structure, and its expression is Li 1.05 Ni 0.55 mn 0.45 o 2 , Li 1.05 Ni 0.55 mn 0.45 o 2 The surface of is also coated with LiF, and LiF accounts for 3wt% of the total mass of the cathode material.

[0043] The preparation method of the cathode material comprises the following steps:

[0044] The first step is to select nickel oxalate as nickel salt and manganese oxalate as manganese salt, fully dissolve nickel oxalate and nickel oxalate into ammonia water and mix evenly so that the molar ratio of nickel to manganese is 55:45, and add lithium carbonate to make nickel oxalate and oxalic acid Nickel is precipitated to obtain a precipitate, which is separated, dried and calcined to obtain a manganese-nickel precursor salt.

[0045] In the second step, the nickel-manganese precursor salt and lithium carbonate are mixed by a ball milling method and then calcined at 1200° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com