Preparation method of sphere-like manganese-rich ternary precursor

A precursor, spherical-like technology, applied in chemical instruments and methods, manganese compounds, electrical components, etc., can solve the problems of difficult pH control of the reaction system, affecting product quality consistency, increasing processing costs, etc., to achieve good fluidity, Low production cost and the effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

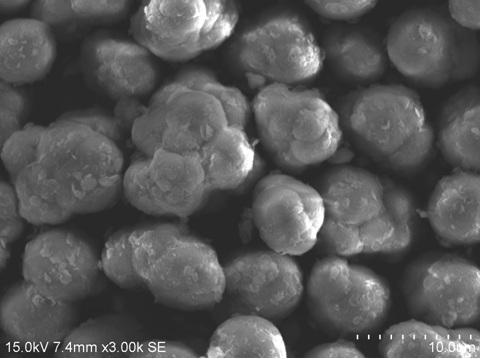

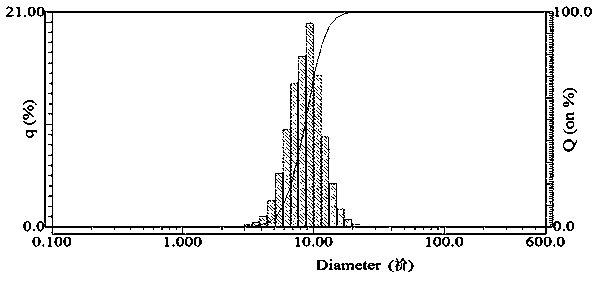

Embodiment 1

[0031] A method for preparing a spherical manganese-rich ternary precursor, comprising the following steps:

[0032] (1) Mix and dissolve nickel sulfate, cobalt sulfate and manganese sulfate with a molar ratio of 30:10:60 with deionized water to obtain a nickel-cobalt-manganese sulfate mixed solution A with a total metal ion concentration of 2.0mol / L;

[0033] A crystal nucleation control agent is also added in the nickel-cobalt-manganese sulfate mixed solution A, the total concentration of the crystal nucleation control agent is controlled at 0.2g / L, and the crystal nucleation control agent is ammonium sulfate;

[0034] (2) Precipitant solution B and complexing agent solution C are prepared with deionized water; the concentration of precipitant solution B is 2.0mol / L, and the precipitant is sodium carbonate; the concentration is 1.0 mol / L prepared with ammonia water and chitosan The complexing agent solution C of mol / L, wherein ammoniacal liquor and chitosan molar ratio are: ...

Embodiment 2

[0039] A method for preparing a spherical manganese-rich ternary precursor, comprising the following steps:

[0040] (1) Mix and dissolve nickel sulfate, cobalt sulfate and manganese sulfate with a molar ratio of 32:11:57 with deionized water to obtain a nickel-cobalt-manganese sulfate mixed solution A with a total metal ion concentration of 2.5mol / L;

[0041]A crystal nucleation control agent is also added in the nickel-cobalt-manganese sulfate mixed solution A, the total concentration of the crystal nucleation control agent is controlled at 1g / L, and the crystal nucleation control agent is polyvinyl alcohol;

[0042] (2) Precipitant solution B and complexing agent solution C are prepared with deionized water; the concentration of precipitant solution B is 1.5mol / L, and the precipitant is sodium carbonate; ammonium bicarbonate and urea are used to prepare a concentration of 2.5 The complexing agent solution of mol / L, wherein ammonium bicarbonate and urea molar ratio are: 2:3;...

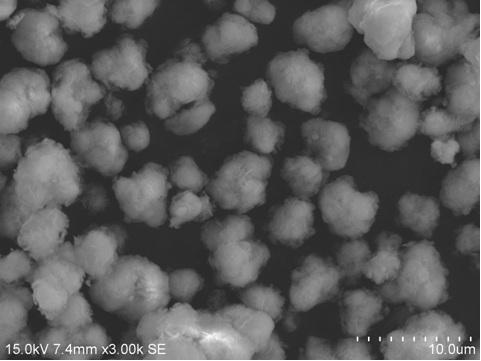

Embodiment 3

[0047] A method for preparing a spherical manganese-rich ternary precursor, comprising the following steps:

[0048] (1) Mix and dissolve nickel sulfate, cobalt sulfate and manganese sulfate with a molar ratio of 25:10:65 with deionized water to obtain a nickel-cobalt-manganese sulfate mixed solution A with a total metal ion concentration of 1.5mol / L;

[0049] A crystal nucleation control agent is also added in the nickel-cobalt-manganese sulfate mixed solution A, the total concentration of the crystal nucleation control agent is controlled at 3g / L, and the crystal nucleation control agent is ethylenediaminetetraacetic acid;

[0050] (2) Precipitant solution B and complexing agent solution C were prepared with deionized water; the concentration of precipitant solution B was 2.0mol / L, and the precipitant was sodium carbonate; prepared with ammonia water and hexamethylenetetramine A complexing agent solution C with a concentration of 1.5mol / L, wherein the molar ratio of ammonia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com