Method of preparing chromium-containing ultrafine WC powder through solid-liquid doping method

A solution and powder technology, applied in the field of ultra-fine WC powder, can solve the problems of unsatisfactory tungsten carbide grain growth, coarse particle size, uneven distribution, etc., and achieve the effect of controllable product quality, fine particle size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

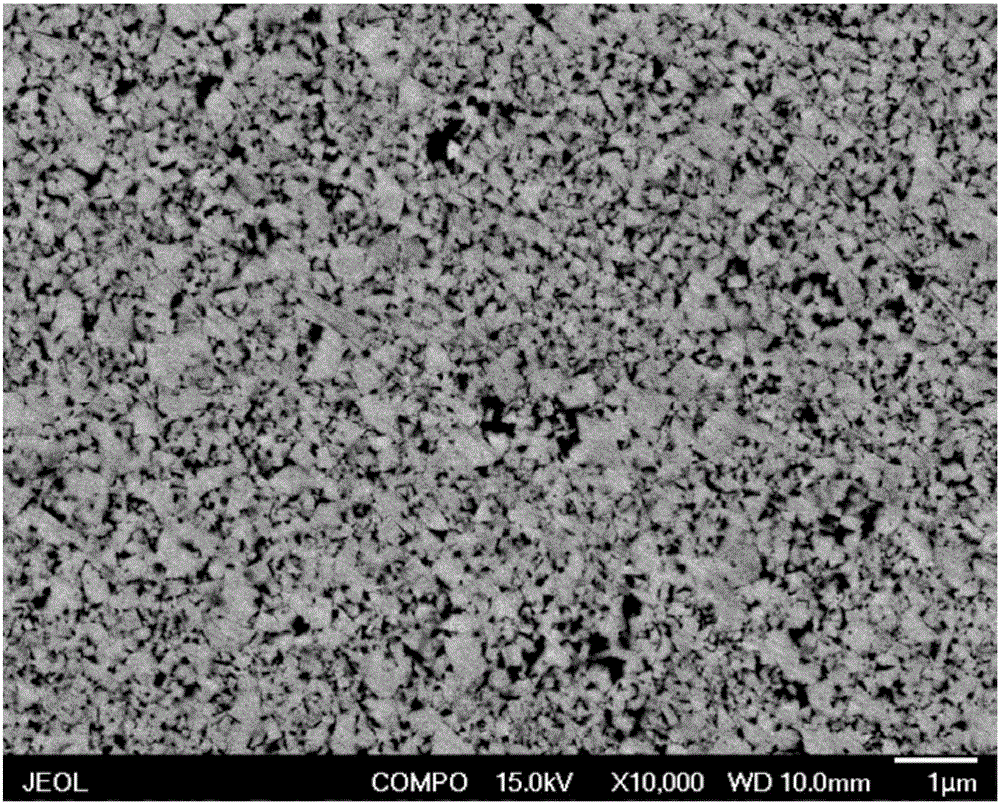

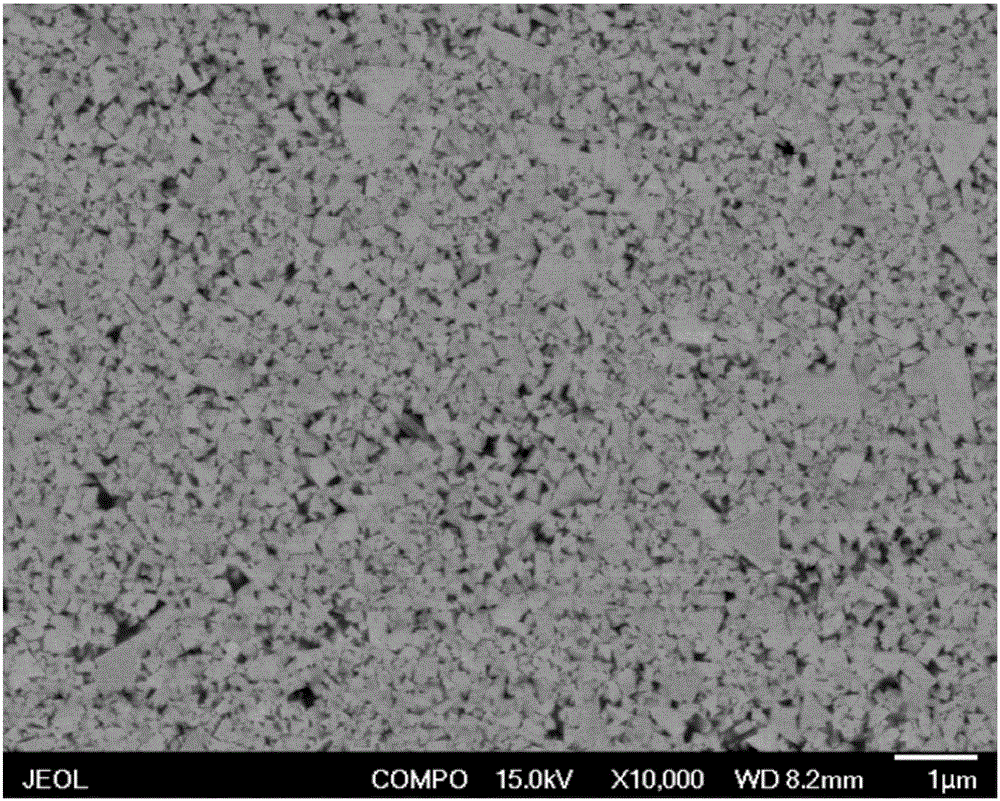

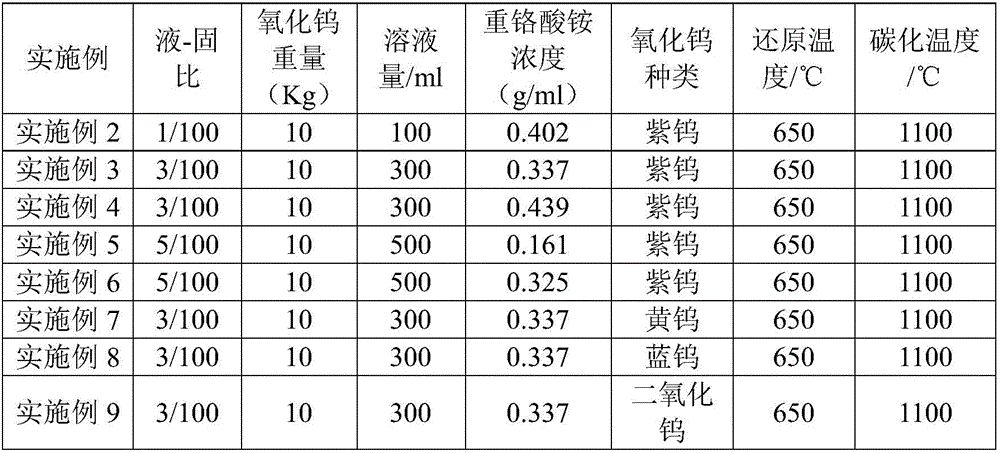

[0024] Embodiment 1: Get 100ml deionized water, add 20.04g ammonium dichromate, be mixed with the ammonium dichromate solution that concentration is 0.2g / ml; Get 10Kg purple tungsten and pack in the mixer, according to liquid-solid ratio: 1ml / 100g Prepare the ammonium dichromate solution, first pour 1 / 3 of the ammonium dichromate solution into the mixer, mix for 1-1.5 hours, then pour 1 / 3 of the ammonium dichromate solution, and mix again 1~1.5h, add the remaining 1 / 3 ammonium dichromate solution into the mixer, and mix for 3.5~4.5h. Unload the mixed violet tungsten from the mixer, and use a reduction furnace in H 2 Atmosphere and temperature of 650°C for 8 hours to obtain tungsten powder and Cr 2 o 3 Mixture of powders. Mix the mixed powder and carbon black in a ball mill for 4-6 hours to obtain tungsten powder and Cr 2 o 3 Powder mixture powder. Mix the mixture powder and carbon black in a ball mill for 4-6 hours, then carbonize in a carbonization furnace for 2 hours i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com