Method for preparing polysilicon in high purity in use for solar cell

A technology for solar cells and preparation devices, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of expensive electron beam equipment, and achieve fast and convenient smelting and impurity removal, low cost, and simple devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

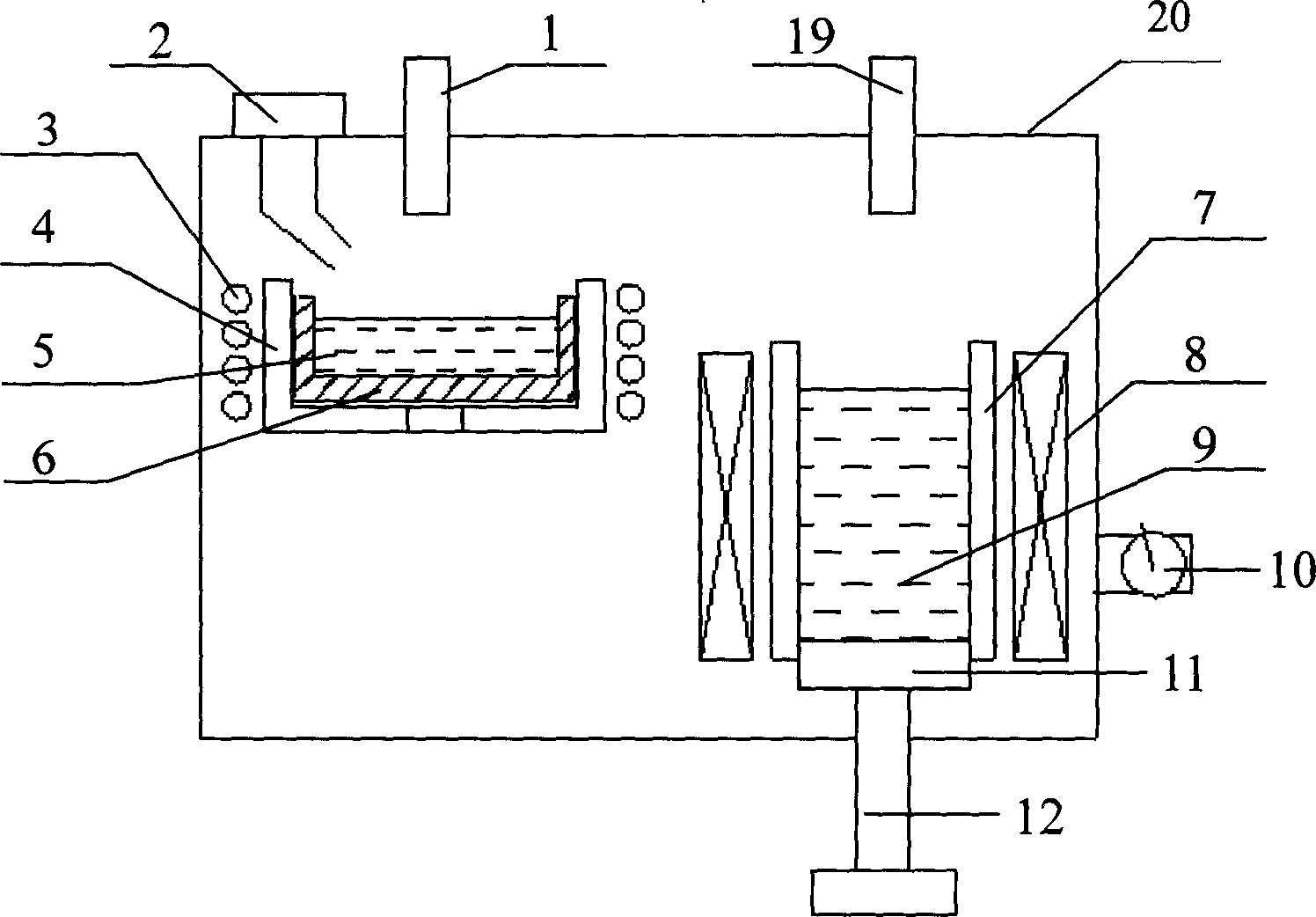

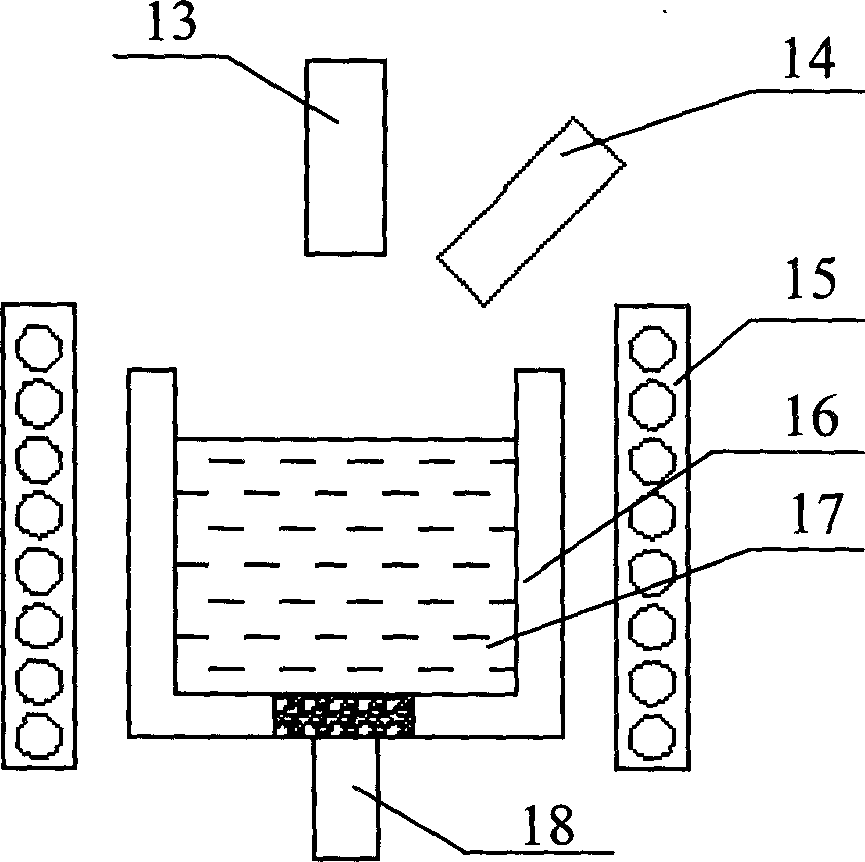

[0022] Put the industrial silicon 5 into the crucible 6, and the vacuum system is evacuated to 10 -2 After Pa, the electromagnetic induction heater 3 is turned on to melt the industrial silicon 5, and the power supply of the holding furnace 8 is turned on simultaneously. When the temperature of the silicon in the crucible 6 reaches 1500°C, keep it warm for 30-60 minutes, move the manipulator to pour the molten silicon into the directional solidification crucible 7, and use the holding furnace 8 to keep the temperature of the liquid silicon 9; then, start the casting system 12 , drive the directional solidification cooling bottom mold 11 to move downward at a speed of 5mm / min, and obtain a slab with a diameter of 160mm and a length of 250mm, and the silicon content is 99.99% through composition testing. Put the directionally solidified billet into the refining crucible 16 of the secondary purification device, use the secondary purification heating furnace 15 to melt and keep it...

Embodiment 2

[0024] Put the industrial silicon 5 into the crucible 6, and the vacuum system is evacuated to 10 -2 After Pa, the electromagnetic induction heater 3 and the plasma gun 1 are turned on to melt the industrial silicon 5, and the power supply of the holding furnace 8 is turned on simultaneously. When the temperature of the silicon in the crucible 6 reaches 1500°C, keep it warm for 30-60 minutes, pull the manipulator to pour the molten silicon into the directional solidification crucible 7, use the holding furnace 8 and the plasma gun 19 to keep the temperature of the liquid silicon 9; then, start The billet drawing system 12 drives the directional solidification cooling bottom mold 11 to move downward at a speed of 3mm / min to obtain a billet with a diameter of 160mm and a length of 250mm, and the silicon content is 99.99% according to the composition test. Put the directionally solidified billet into the refining crucible 16 of the secondary purification device, use the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com