Manufacturing method of liquid asphalt modifier

A manufacturing method, liquid asphalt technology, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of high processing cost, limited application, material aging, etc., to save equipment investment, simplify production process, avoid material aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

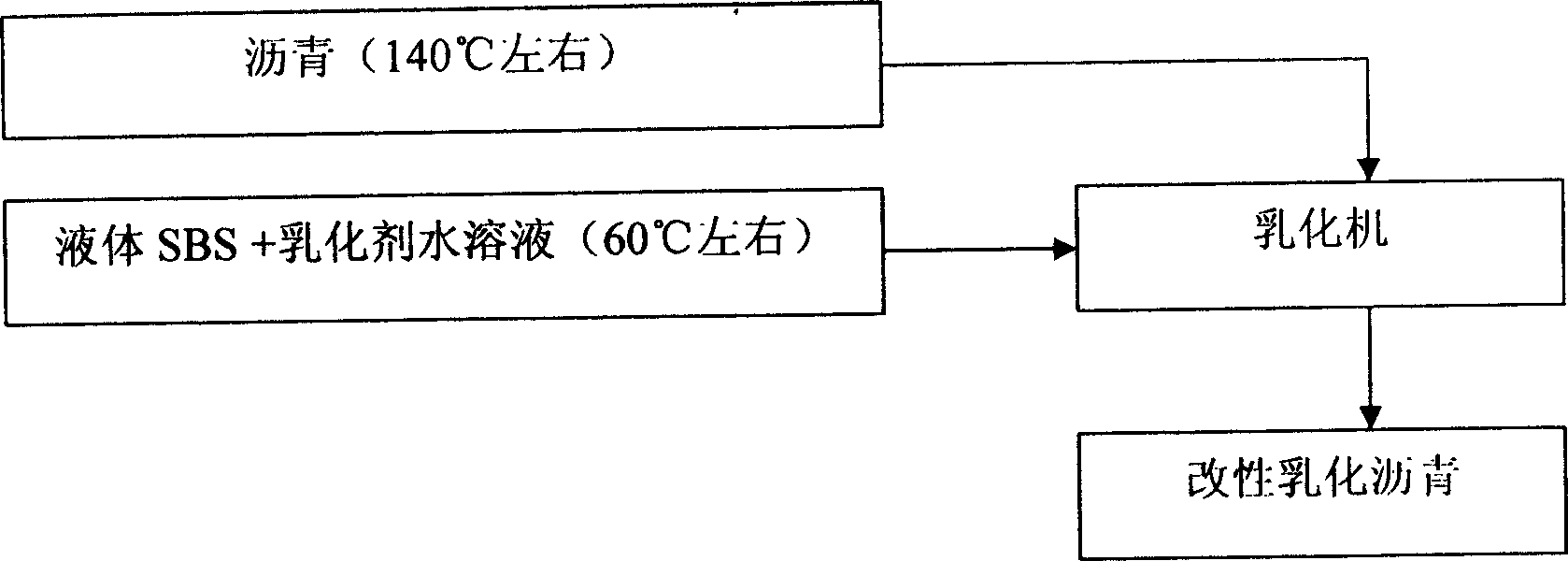

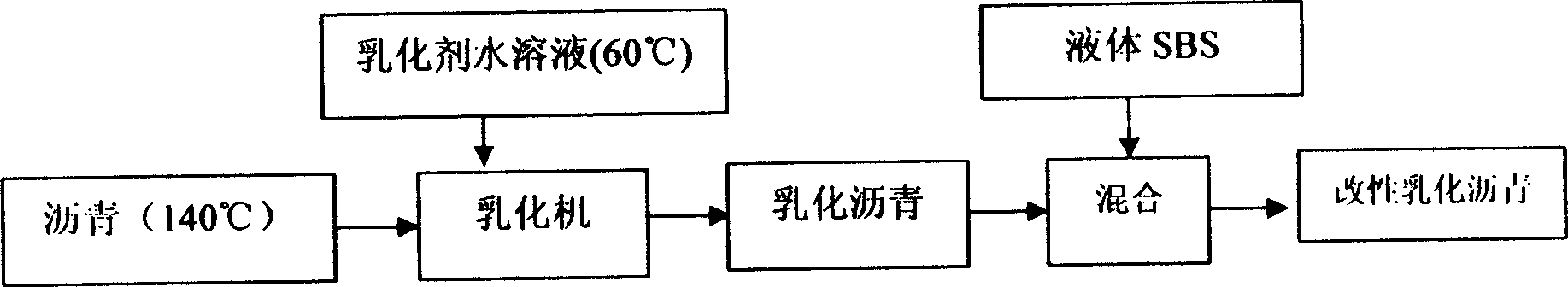

Method used

Image

Examples

Embodiment 1

[0021] First, 20 kilograms of solid SBS (produced by Beijing Yanshan Petrochemical Company Rubber Factory, Guochuang 1 # ) and 60 kg of toluene were added to a reaction kettle equipped with a common stirrer and a high-speed shearing device, heated to 70°C, and maintained at a temperature not lower than this until the SBS was completely dissolved, and then 0.5 kg of polydecanol was added to the kettle. Oxyethylene ether sodium sulfate, 0.5 kg of OP-10 non-ionic surfactant and 60 kg of water and mix evenly, stop stirring, start the high-speed shear emulsifier, emulsify for 30 minutes, when the emulsified liquid particle diameter is 2 μm When the time is below, stop the high-speed shear emulsifier, and finally distill at 30-60°C and 0.070-0.085Mpa pressure to recover the toluene in it to obtain liquid SBS asphalt modifier.

Embodiment 2

[0023] The tensio-active agent that adds in reactor is 0.5 kilogram of cetyltrimethylammonium chloride and 0.5 kilogram of lauryl amido alkylimidazoline, and all the other are with embodiment 1.

Embodiment 3

[0025] First, 20 kilograms of solid SBS (produced by Beijing Yanshan Petrochemical Company Rubber Factory, Guochuang 1 # , star-shaped) and 60 kg of benzene are added to a reaction kettle equipped with a common stirrer and a high-speed shearer, heated to 70 ° C, and maintained at a temperature not lower than this until the SBS is completely dissolved, and then 0.5 kg of alkyl Phenol polyoxyethylene ether nonionic surfactant, start the stirrer on the reactor, make surfactant all be dissolved in it, then add the preprepared by 0.5 kilogram of sorbitan monostearate polyoxygen Mix the mixture of vinyl ether, 0.5 kg starch and 60 kg water evenly, stop stirring, start the high-shear emulsifier, emulsify for 30 minutes, and stop the high-shear emulsifier when the emulsified particle diameter is below 2 μm. Finally, distill at 30-60°C and 0.070-0.085Mpa pressure to recover the benzene in it to obtain liquid SBS asphalt modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com