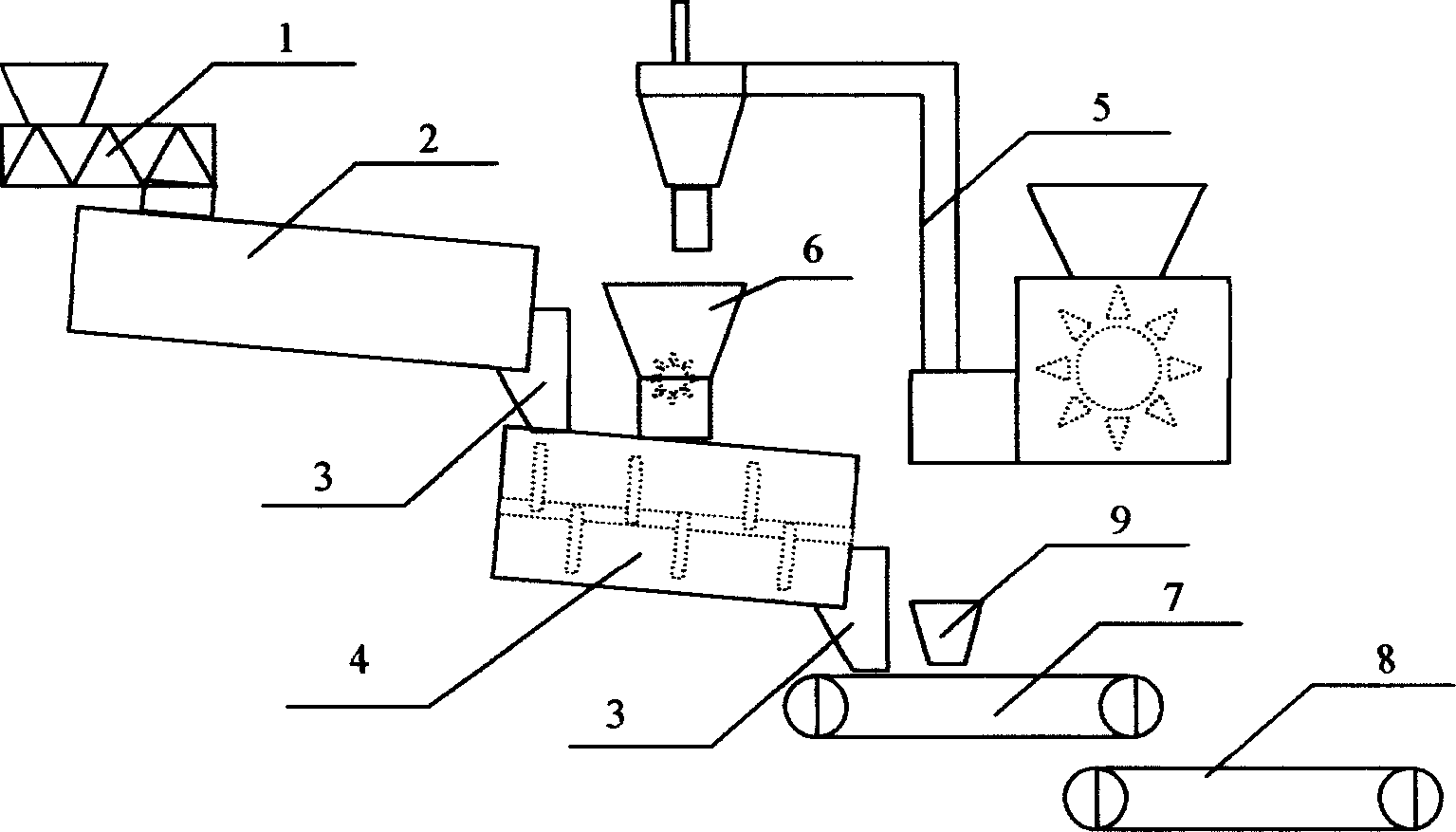

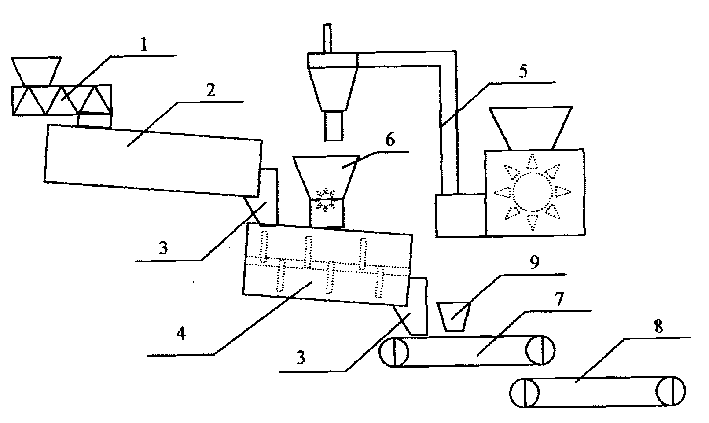

Waste plastic processing method for increasing coke strength and its apparatus system

A processing method and coke strength technology, which is applied in the field of waste plastic processing methods and systems for improving coke strength, can solve the problems of low waste plastic processing capacity, failure to improve, and complicated waste plastic processing technology, so as to save investment and operation Cost, increase coke strength, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0023] Concrete embodiment: carry out test with 200kg test coke oven, the specification of test coke oven is: body of furnace effective length 800mm, effective height 900mm, width is 450mm, coal charge 230kg (dry coal), coking time is 18 hours, coke cake The core temperature is greater than 950°C. The raw materials used in this embodiment include coking coal blending (BC), waste plastics (MP) and coal pitch; waste plastics are processed according to the above-mentioned process, first the waste plastics are broken into pieces smaller than 10 mm, and then a certain amount of coal is preheated to 190°C, then mix waste plastic fragments with preheated coal, co-heating and melting time is 2min, take out the mixed material and mix with a certain amount of coking coal or add a certain amount of coal pitch to prepare 200kg coke oven test raw material. The coke produced in the 200kg coke oven coking test was subjected to sieving test and drum test to test its crushing strength (M40) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com