Polycarboxylate composite water reducing agent suitable for low-cementitious material concrete and preparation method thereof

A technology of composite water reducer and polycarboxylic acid, which is applied in the field of concrete with low cementitious materials, can solve the problems of compound water reducer such as easy deterioration, poor compatibility, and affecting use, and achieve good workability and good frost resistance , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

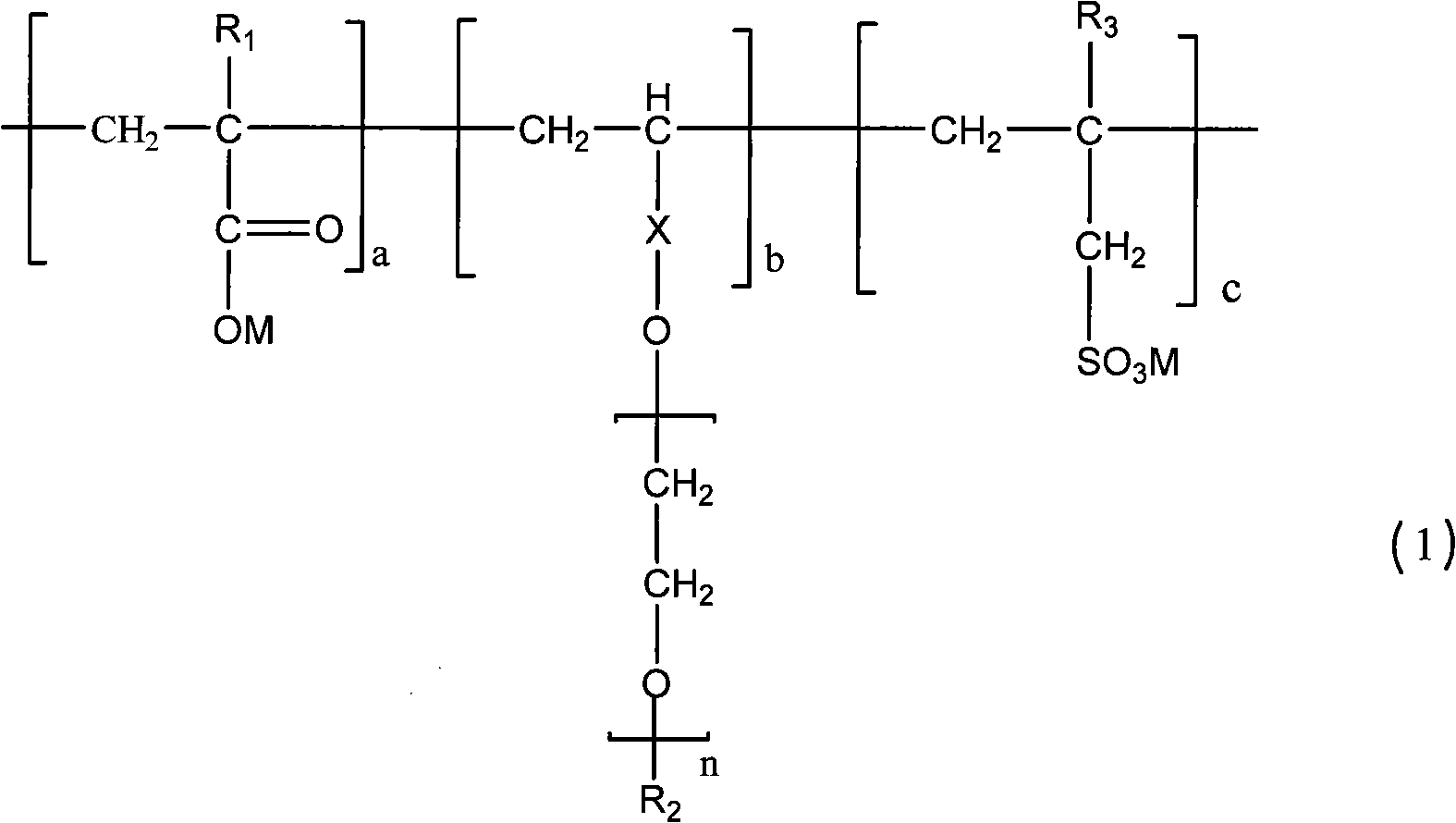

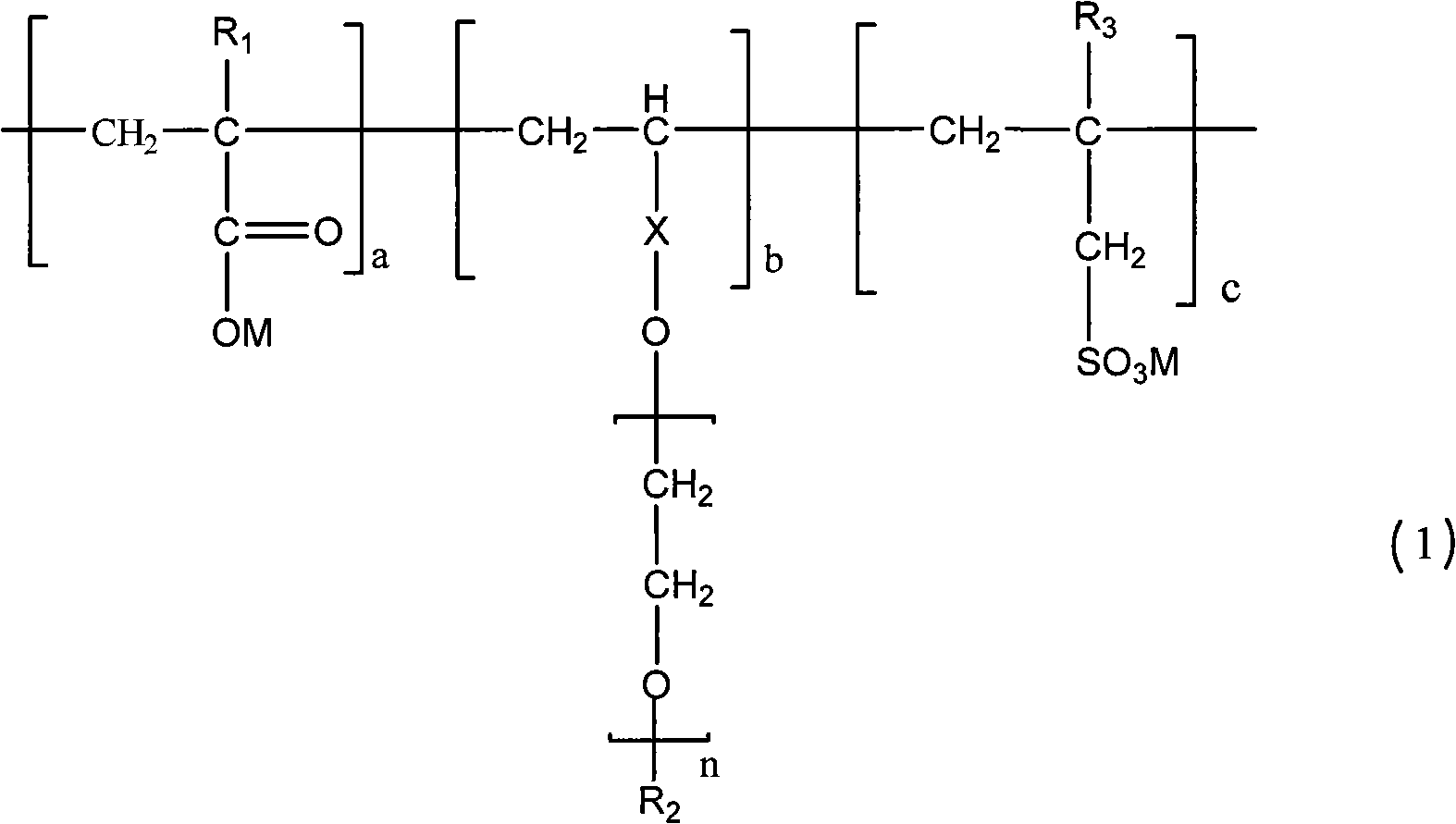

Method used

Image

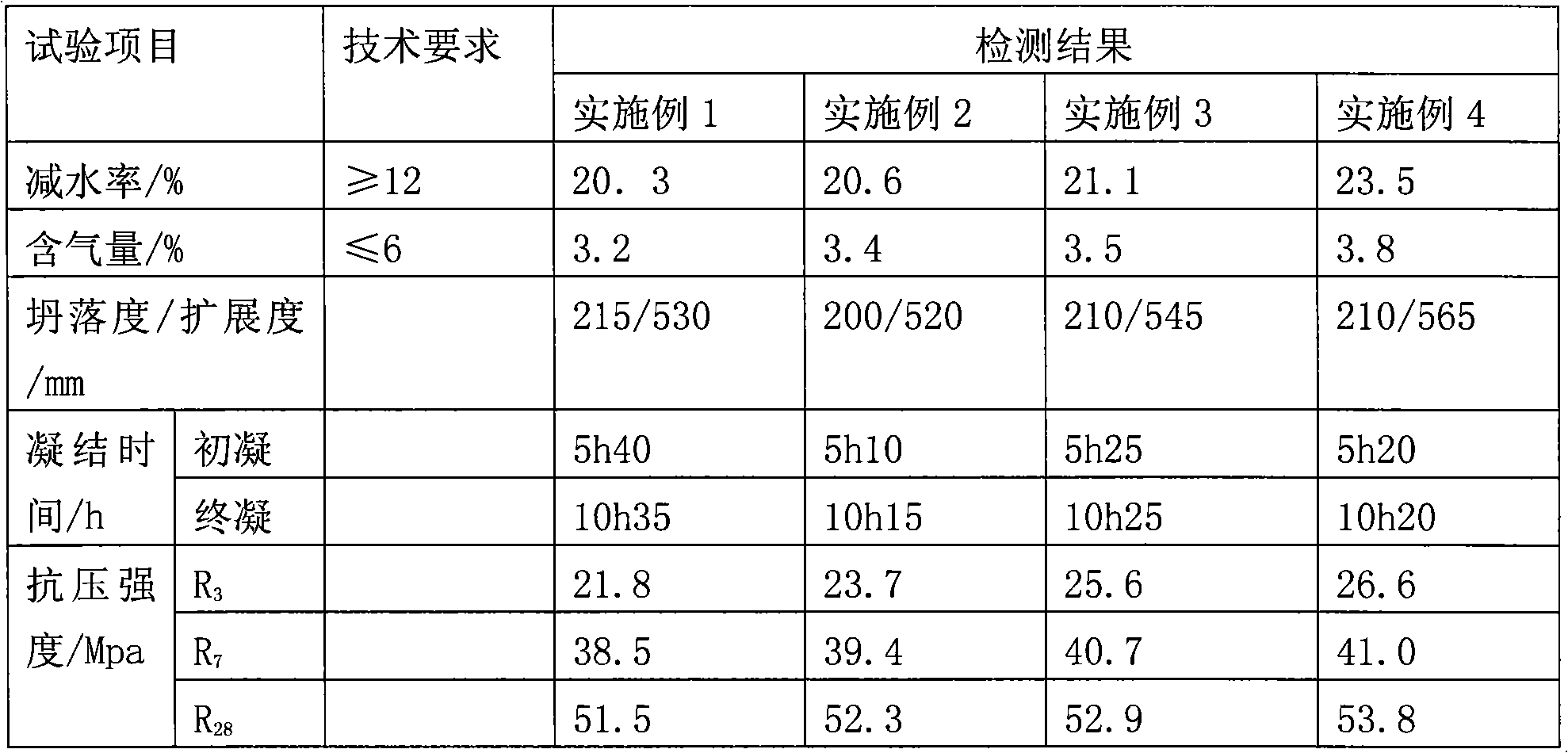

Examples

Embodiment 1

[0023] In the 1000L reactor, 100kg of polycarboxylate superplasticizer (solid content 40%), 15kg of sodium gluconate (retarder), 0.3kg of defoamer, 0.45kg of air-entraining agent, 1.5kg of preservative, and tap water were successively put into the 1000L reactor. 383.5kg, stirred for about 20 minutes to make it dissolve into a uniform solution to obtain a polycarboxylic acid composite water reducer.

[0024] The polycarboxylate high-efficiency water reducer is the ZJ-SS-02 type water reducer produced by China Construction Commercial Concrete Company.

[0025] The defoamer is a polyether defoamer, selected: HFSP-6 defoamer produced by Nantong Hongfeng Industrial Auxiliary Co., Ltd.

[0026] The air-entraining agent is a triterpene saponin air-entraining agent, selected: "tea saponin" brand air-entraining agent produced by Zhejiang Tianma Chemical Co., Ltd.

[0027] The preservative is a composite preservative of parabens and formaldehyde (mixed by parabens and formaldehyde), an...

Embodiment 2

[0030] In the 1000L reaction kettle, put 100kg of polycarboxylate high-efficiency water reducer (solid content 40%), 12kg of borax (retarder), 0.3kg of defoamer, 0.45kg of air-entraining agent, 1.5kg of preservative, and 385.5kg of tap water , stirred for about 20 minutes to make it dissolve into a uniform solution, and the prepared solution concentration was 10.85% (mass), to obtain a polycarboxylic acid composite water reducer.

[0031] The polycarboxylate high-efficiency water reducer is the ZJ-SS-02 type water reducer produced by China Construction Commercial Concrete Company.

[0032] The defoamer is a polyether defoamer, selected: HFSP-6 defoamer produced by Nantong Hongfeng Industrial Auxiliary Co., Ltd.

[0033] The air-entraining agent is a triterpene saponin air-entraining agent, selected: "tea saponin" brand air-entraining agent produced by Zhejiang Tianma Chemical Co., Ltd.

[0034] The preservative is a compound preservative of parabens and formaldehyde (mixed by...

Embodiment 3

[0037] In the 1000L reactor, 100kg of polycarboxylate high-efficiency water reducer (solid content 40%), 10kg of sodium gluconate (retarder), 5kg of borax, 0.3kg of defoamer, 0.45kg of air-entraining agent, and 1.5kg of preservative were successively put into the 1000L reactor. kg, 383.5kg of tap water, stirred for about 20 minutes to make it dissolve into a uniform solution, and the prepared solution concentration was 11.45% (by mass), to obtain a polycarboxylic acid composite water reducer.

[0038] The polycarboxylate high-efficiency water reducer is the ZJ-SS-02 type water reducer produced by China Construction Commercial Concrete Company.

[0039] The defoamer is a polyether defoamer, selected: HFSP-6 defoamer produced by Nantong Hongfeng Industrial Auxiliary Co., Ltd.

[0040] The air-entraining agent is a triterpene saponin air-entraining agent, selected: "tea saponin" brand air-entraining agent produced by Zhejiang Tianma Chemical Co., Ltd.

[0041] The preservative i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com