Silver ornament cleaning device

A technology for cleaning devices and silver jewelry, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of reducing cleaning work efficiency, affecting the gloss of silver jewelry, and low cleaning efficiency of cleaning devices. Achieve the effect of reducing labor costs, high cleaning efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

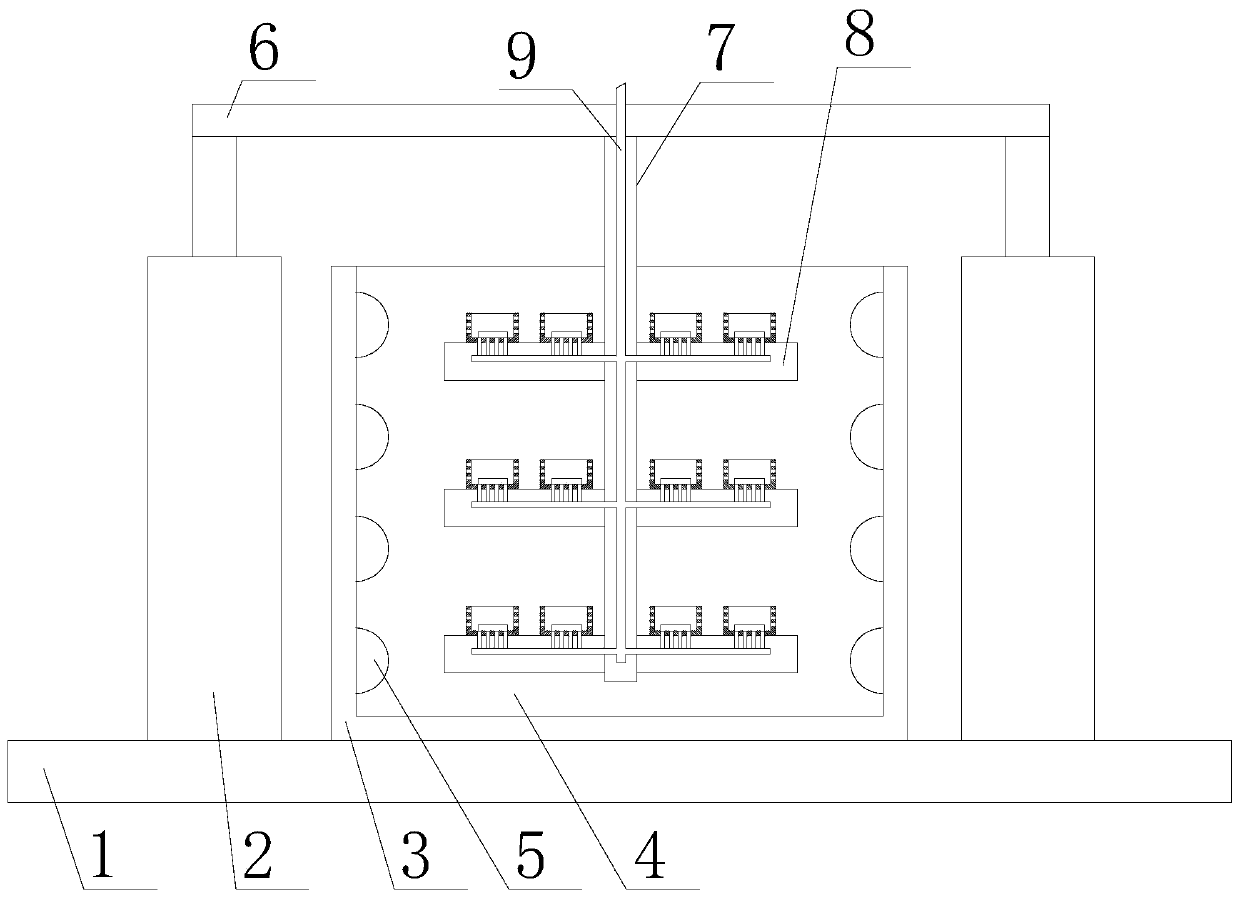

[0019] As an embodiment, the driving member 2 adopts an air cylinder or a hydraulic rod for driving the support plate 8 to move up and down.

[0020] As an embodiment, there are two driving parts 2 located on both sides of the cleaning part 3, and the connecting plate 6 is evenly stressed, which can effectively prevent the connecting plate 6 from breaking.

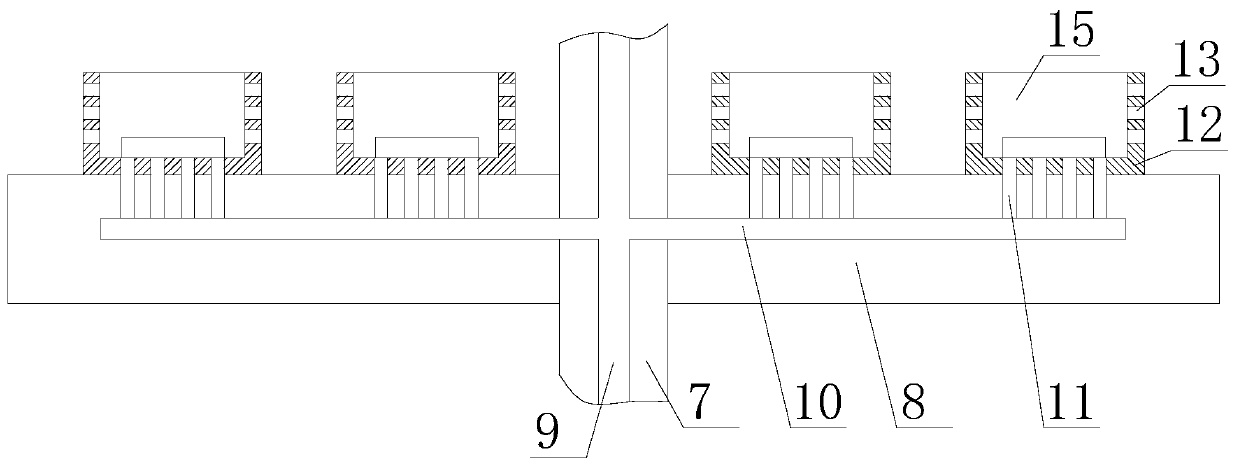

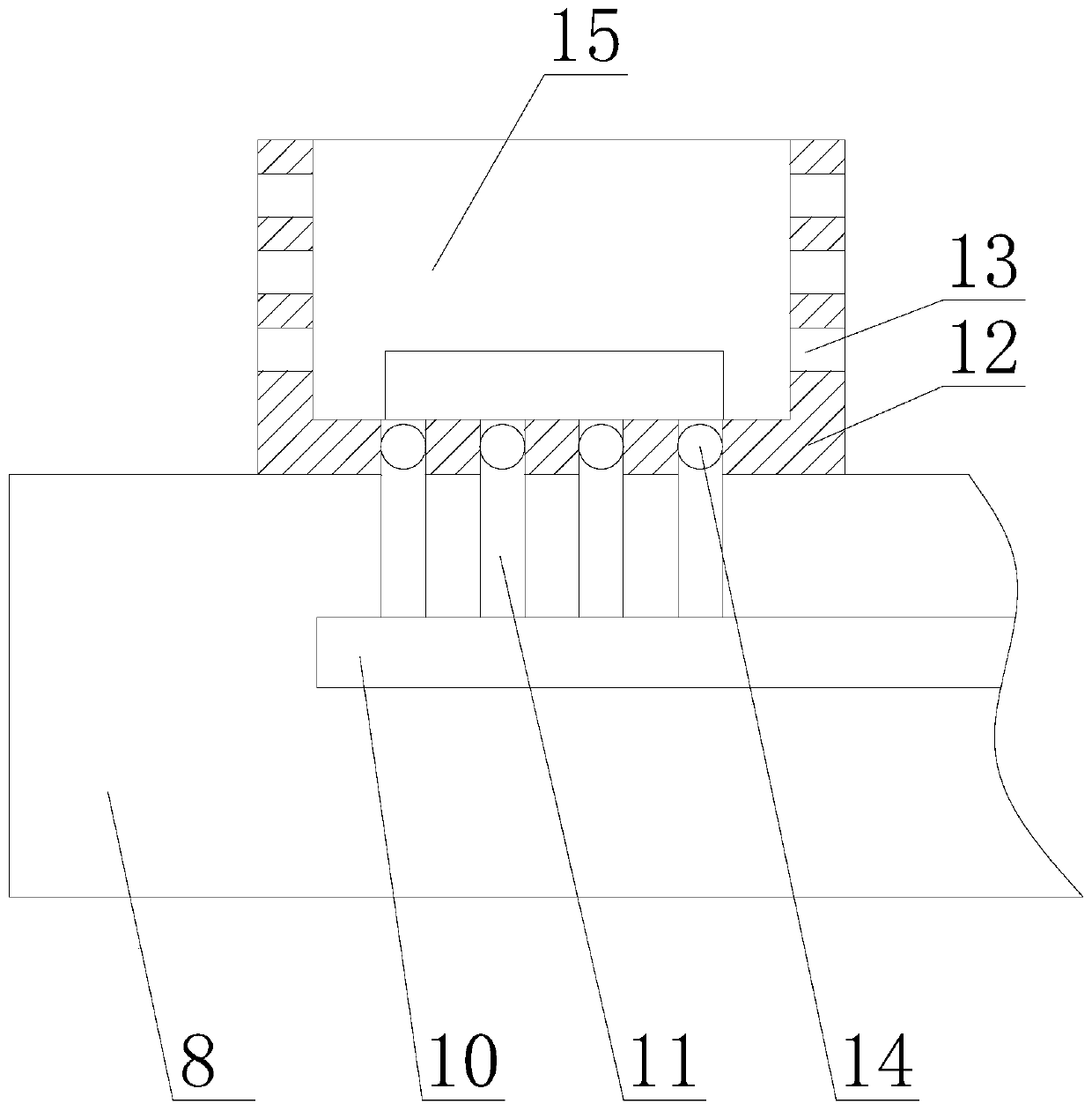

[0021] As an implementation, such as figure 2 and image 3 As shown, the side of the placement block 2 is provided with a number of through holes 13, the through holes 13 communicate with the placement groove 15, so that the ultrasonic wave sent by the ultrasonic generator 5 enters the placement groove 15 through the through holes 13, and then the silver jewelry Carry out all-round cleaning.

[0022] In this embodiment, the connecting column 7 is provided with an air channel 9, the inlet of the air channel 9 is connected to the outlet of the air compressor through a pipeline, and the support plate 8 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com