Laser cutting machine

A technology of laser cutting machine and machine tool, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of high cutting cost, achieve the effect of large processing range, high precision, and reduce the content of air cutting dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

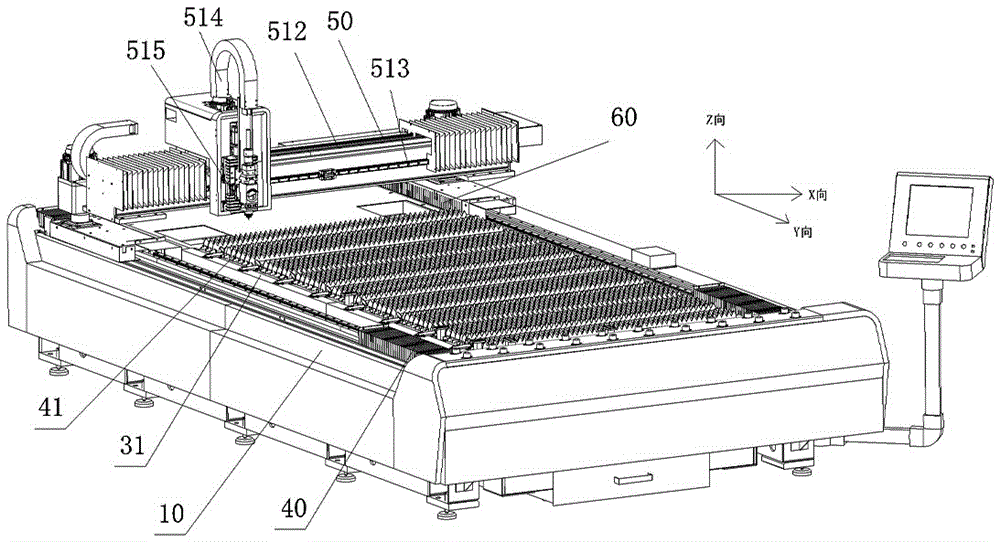

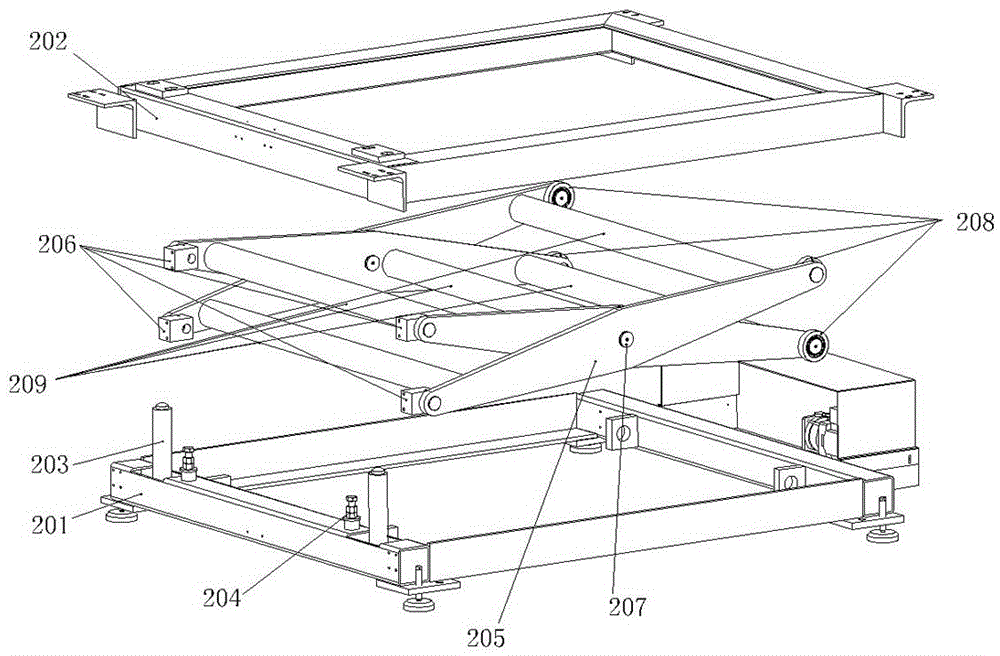

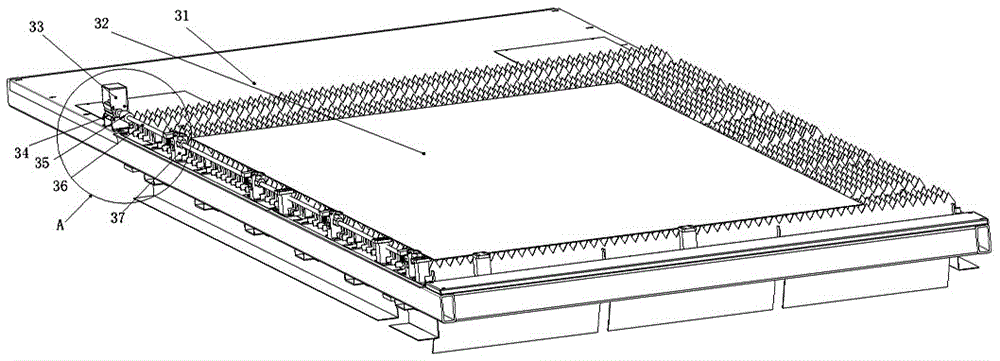

[0029] see Figure 1-11As shown, the present invention relates to a laser cutting machine, including a machine tool body 10, a lifting mechanism is provided in the machine tool body 10, a worktable 31 assembly is arranged above the lifting mechanism, and the workbench 31 assembly includes The workbench 31 and the workbench needle plate 41 arranged on the workbench 31, the side of the workbench 31 in the Y-axis direction is provided with a plate clamping mechanism 30, and the workbench needle plate 41 is provided with several A plate universal translation support mechanism 40 parallel to the side of the X-axis direction of the workbench 31, a crossbeam 50 is provided above the side of the X-axis direction of the workbench 31, and a ventilation and dust removal mechanism 60 is provided below the crossbeam 50. The ventilation and dust removal mechanism 60 is enclosed on the outside of the workbench needle plate 41 .

[0030] The machine tool body 10 includes a frame and a guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com