Silver alloy and method for preparing high-temperature transparent enamel decorating silver jewelry by using silver alloy

A technology of silver alloy and silver-copper alloy, which is applied in the field of silver alloy and its use in the preparation of high-temperature transparent enamel inlaid silver jewelry, can solve the problem of improper selection of process methods and process parameters, unreasonable process settings, and failure to reach the application level And other problems, to achieve the effect of excellent high temperature oxidation resistance, good gloss, high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

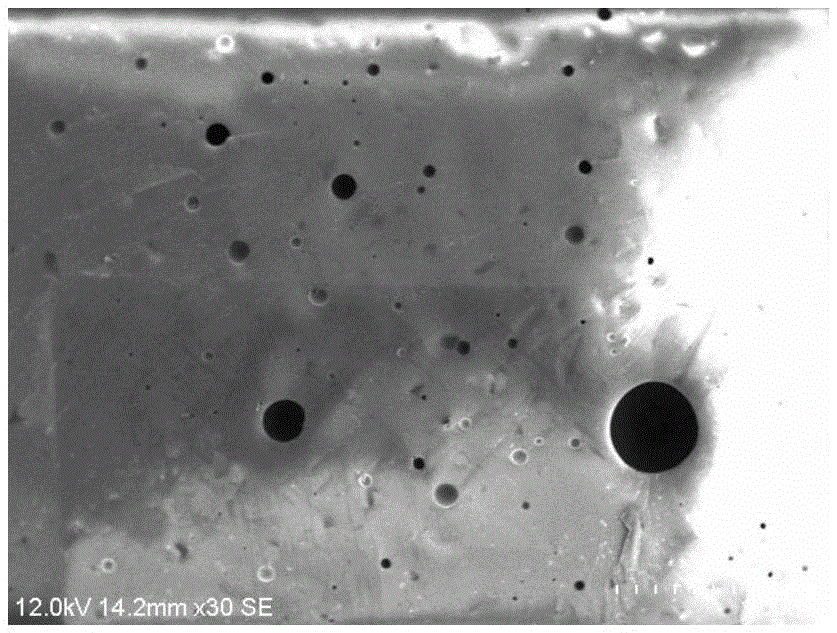

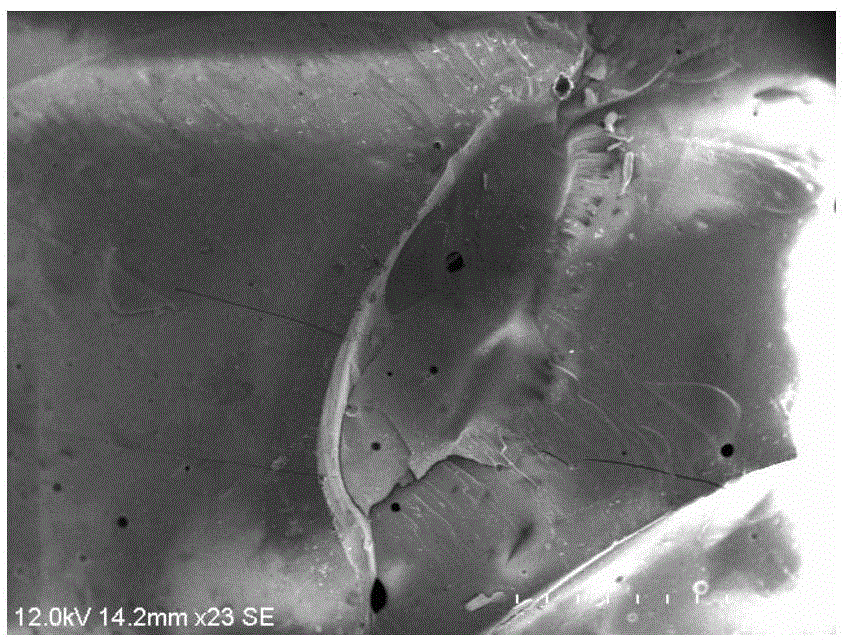

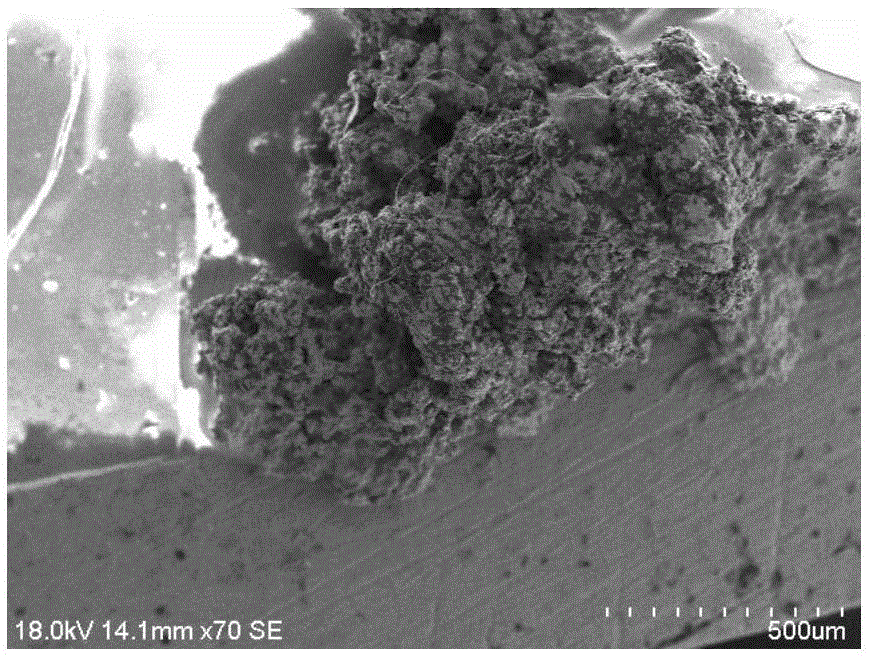

Image

Examples

Embodiment 1

[0037] The present embodiment is used for the silver alloy of enamel inlaid jewelry, and its composition comprises the following components by mass percentage: 94.39wt% silver, 2.43wt% copper, 2.35wt% zinc, 0.70wt% palladium, 0.074wt% silicon, 0.008wt% scandium, and the balance is unavoidable impurities.

[0038] The preparation method of silver alloy described in the present embodiment comprises the following steps:

[0039] 1) Weigh the following raw materials in mass percentage: 1.6wt% silver-scandium alloy (containing 0.5wt% scandium), 7wt% silver-palladium alloy (containing 10wt% palladium), 5wt% silver-copper alloy (containing 20wt% copper), 12wt% Silver-zinc alloy (20wt% zinc), 1.5wt% copper-silicon alloy (5wt% silicon), 72.9wt% pure silver;

[0040] 2) Melting in a vacuum induction furnace: Put the above-mentioned weighed raw materials into a graphite crucible, mix well, fill it tightly and close the furnace cover, evacuate to 5.2Pa, then fill with industrial pure arg...

Embodiment 2

[0042] This embodiment is used for the silver alloy of enamel inlaid jewelry, and its composition comprises the following components by mass percentage: 94.20wt% silver, 2.40wt% copper, 2.98wt% zinc, 0.30wt% palladium, 0.053wt% silicon, 0.007wt% scandium, and the balance is unavoidable impurities.

[0043] The preparation method of silver alloy described in the present embodiment comprises the following steps:

[0044] 1) Weigh the following raw materials in mass percentage: 1.5wt% silver-scandium alloy (containing 0.5wt% scandium), 3.1wt% silver-palladium alloy (containing 10wt% palladium), 12.5wt% silver-zinc alloy (containing 20wt% zinc), 1.1wt% copper-silicon alloy (containing 5wt% silicon), 2wt% copper-zinc alloy (containing 30wt% zinc), 81.8wt% pure silver;

[0045] 2) Melting in a vacuum induction furnace: Put the above-mentioned weighed raw materials into a graphite crucible, mix well, fill it tightly and close the furnace cover, vacuumize to 4.9Pa, and then fill with i...

Embodiment 3

[0047] This embodiment is used for the silver alloy of enamel inlaid jewelry, and its composition comprises the following components by mass percentage: 94.97wt% silver, 2.14wt% copper, 2.16wt% zinc, 0.60wt% palladium, 0.084wt% silicon, 0.007wt% scandium, and the balance is unavoidable impurities.

[0048] The preparation method of silver alloy described in the present embodiment comprises the following steps:

[0049] 1) Weigh the following raw materials in mass percentage: 1.5wt% silver-scandium alloy (containing 0.5wt% scandium), 6wt% silver-palladium alloy (containing 10wt% palladium), 2.6wt% silver-copper alloy (containing 20wt% copper), 11wt% %Silver-zinc alloy (containing 20wt% zinc), 1.7wt% copper-silicon alloy (containing 5wt% silicon), 77.2wt% pure silver;

[0050] 2) Melting in a vacuum induction furnace: Put the above-mentioned weighed raw materials into a graphite crucible, mix well, fill it tightly and close the furnace cover, vacuumize to 5.3Pa, and then fill w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com