Electroplating anti-black method of silver ornament

A technology of silver jewelry and silver electroplating, which is applied in jewelry and other fields, can solve the problems of oxidation and blackening of silver jewelry and affect the aesthetics of silver jewelry, and achieve the effect of avoiding blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

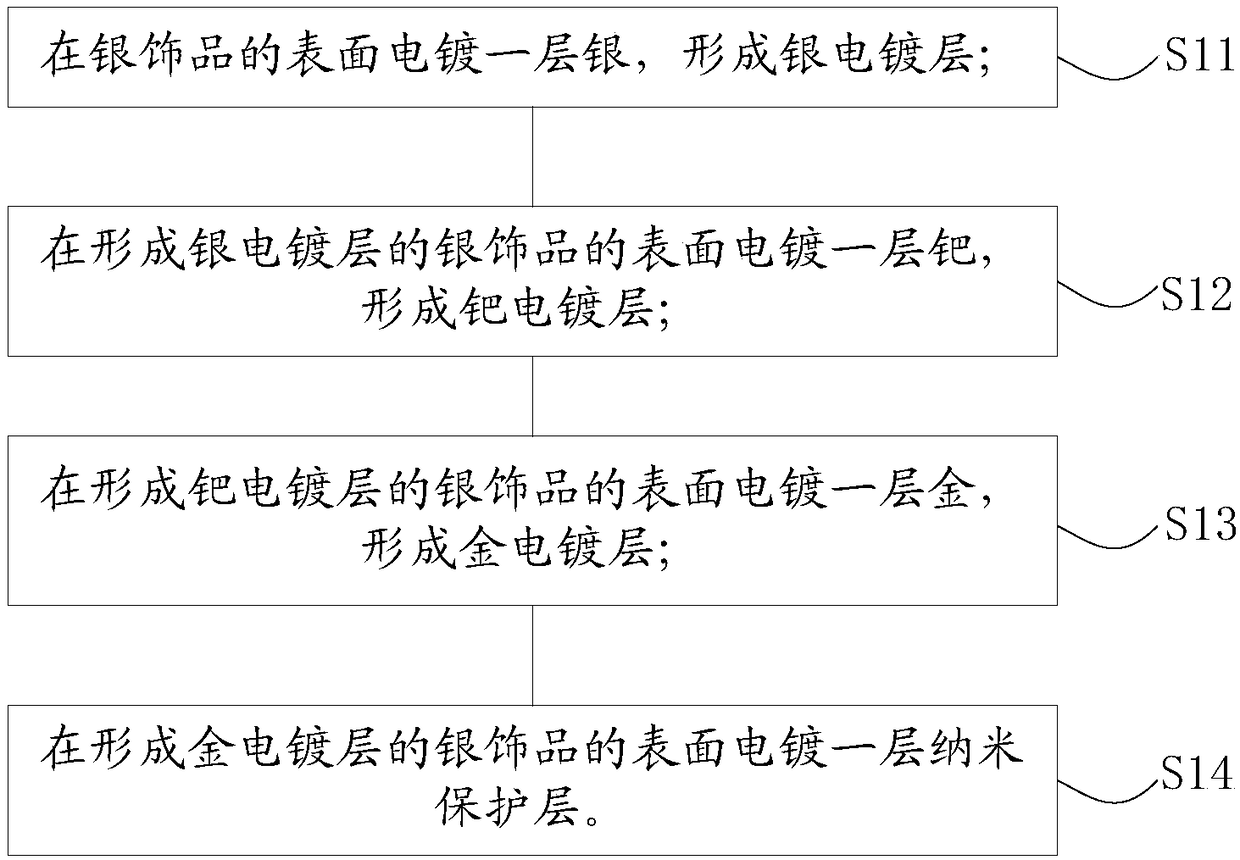

[0035] refer to figure 1 , an anti-blackening method for silver jewelry electroplating, comprising steps,

[0036] S11, electroplating a layer of silver on the surface of the silver ornament to form a silver electroplating layer;

[0037] S12, electroplating a layer of palladium on the surface of the silver ornament forming the silver electroplating layer to form a palladium electroplating layer;

[0038] S13, electroplating a layer of gold on the surface of the silver ornament forming the palladium electroplating layer to form a gold electroplating layer;

[0039] S14, electroplating a layer of nano protective layer on the surface of the silver jewelry forming the gold electroplating layer.

[0040] Preferably, a nano protective layer is electroplated on the surface of the silver jewelry forming the gold electroplating layer; the nano protective layer is a nano colloid protective layer.

[0041] In this embodiment, the silver protective layer, the palladium protective laye...

Embodiment 2

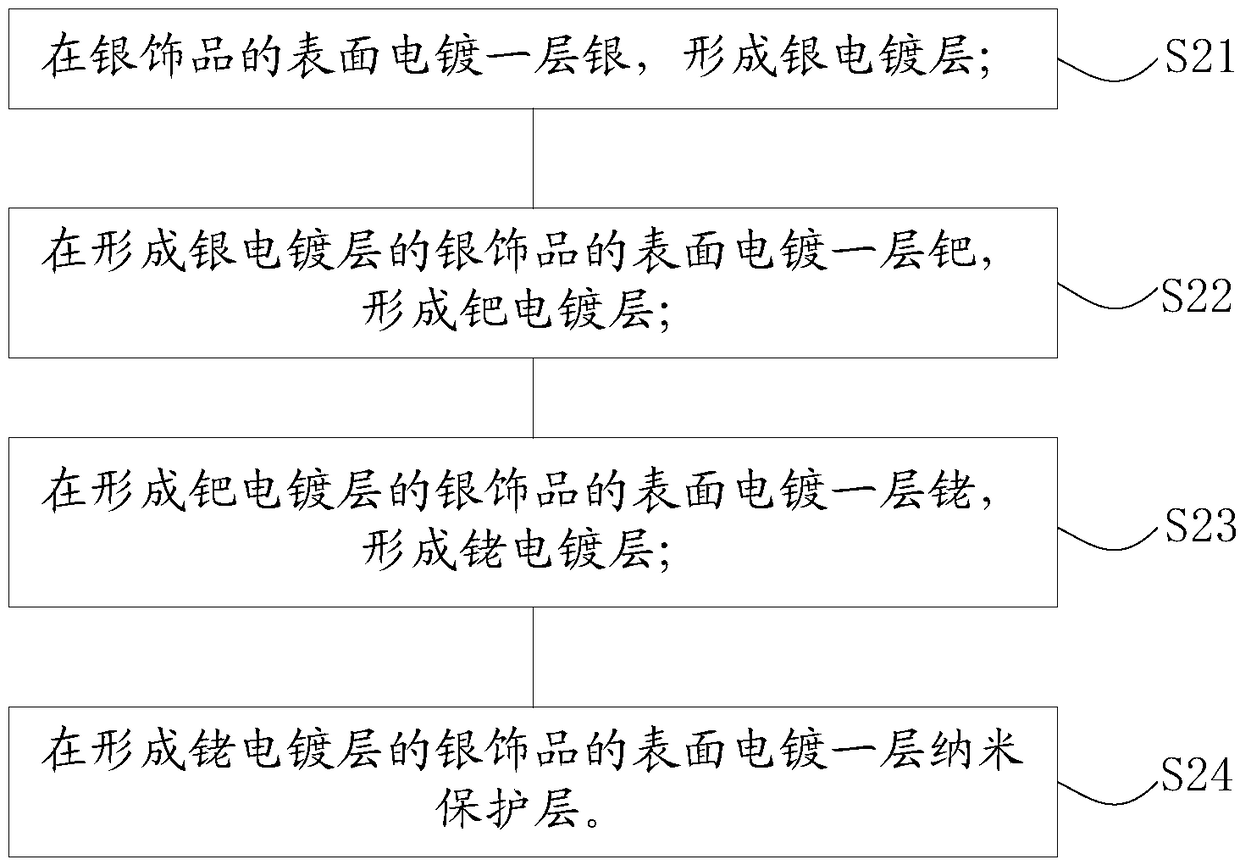

[0043] refer to figure 2 , an anti-blackening method for silver jewelry electroplating, comprising steps,

[0044] S21, electroplating a layer of silver on the surface of the silver ornament to form a silver electroplating layer;

[0045] S22, electroplating a layer of palladium on the surface of the silver ornament forming the silver electroplating layer to form a palladium electroplating layer;

[0046] S23, electroplating a layer of rhodium on the surface of the silver ornament forming the palladium electroplating layer to form a rhodium electroplating layer;

[0047] S24, electroplating a layer of nano protective layer on the surface of the silver ornaments forming the rhodium electroplating layer.

[0048] Preferably, a nano protective layer is electroplated on the surface of the silver jewelry forming the rhodium electroplating layer; the nano protective layer is a nano colloid protective layer.

[0049] In this embodiment, the silver protective layer, the palladium ...

Embodiment 3

[0051] In a specific embodiment, a layer of silver is electroplated on the surface of the silver ornament to form a silver electroplating layer; the purity of the electroplated silver is 99.99%.

[0052] Preferably, a layer of silver is electroplated on the surface of the silver ornament to form a silver electroplating layer, and the thickness of the silver electroplating layer is 3 microns.

[0053] Preferably, a layer of palladium is electroplated on the surface of the silver jewelry forming the silver electroplating layer to form a palladium electroplating layer; the thickness of the palladium electroplating layer is not less than 0.5 microns.

[0054] In this embodiment, the thickness of the electroplated silver protective layer is 3 micrometers, and the thickness of the palladium electroplating layer is not less than 0.5 micrometers. Using the electroplating layer of this size combination in the silver jewelry can make the silver jewelry not easy to wear during long-term w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com