Novel technique for producing gold/silver jewellery

A new craft and jewelry technology, applied in applications, jewelry, clothing, etc., can solve the problems of large loss, waste of precious metals, cumbersome process flow, etc., and achieve the effect of reduced production cost, low price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

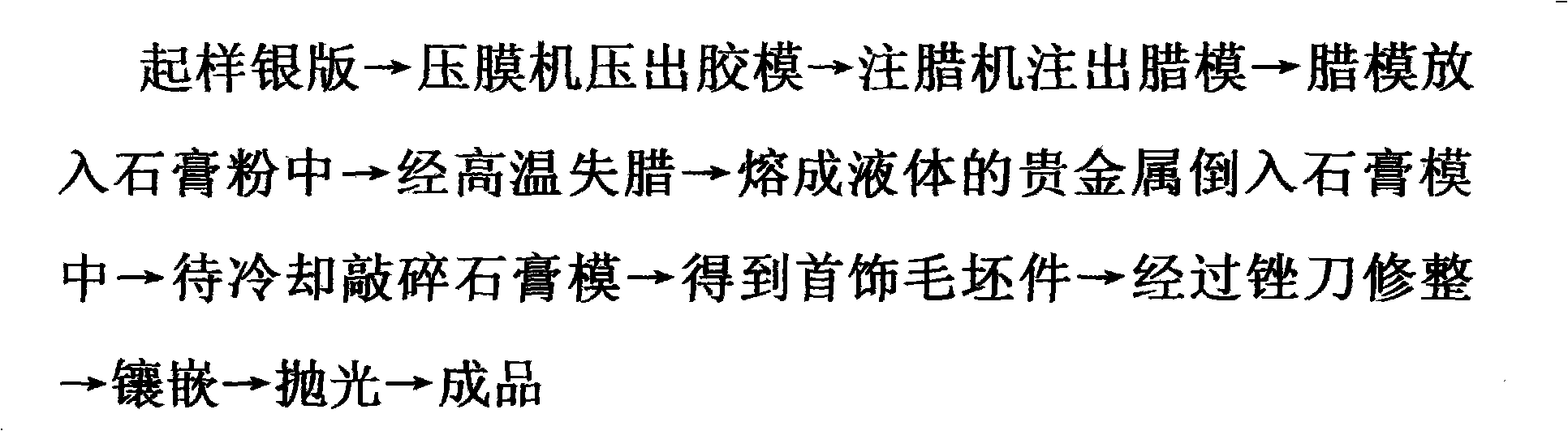

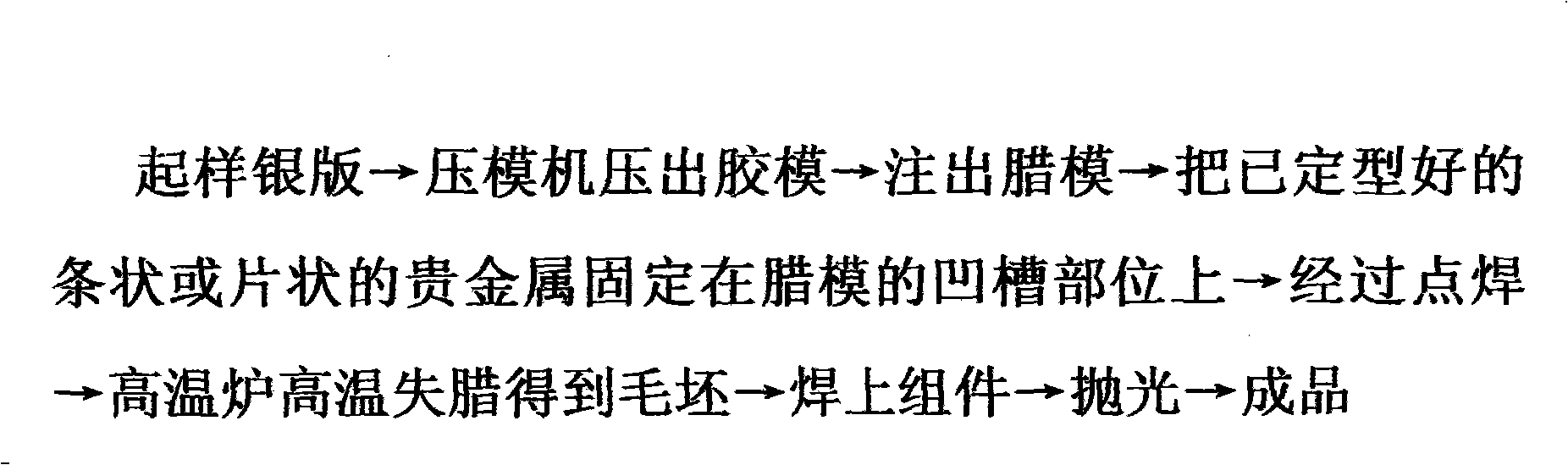

Method used

Image

Examples

specific Embodiment 1

[0012] Specific embodiment 1, such as putting the shaped strips of precious metals, which are shaped like a lantern skeleton, into the grooves in the wax mold, and then clamp the strips of precious metals with a special pliers The head, so that all the heads are gathered together, and then spot-weld the two heads with a spot welding machine to form a lantern skeleton shape, and then put the wax mold into a high-temperature furnace to melt the wax mold to make a finished blank, and then match it with a point The components that make up the necklace are welded on and polished to complete the finished product.

specific Embodiment 2

[0013] Specific embodiment 2, put into the double-sided groove of solid wax mould, the head of each sheet precious metal is spot-welded with the head with spot welding machine as piece by piece precious metal, then laps with connecting sheet or connecting pipe Then connect them together by spot welding with a spot welding machine, and then lose wax at high temperature to make a cage-like semi-finished blank, which is also connected by component spot welding to form a chain. Such shapes can be varied, such as olive-shaped, spherical, gourd-shaped, and strip or sheet precious metals can also be in the form of filaments. Strip or flake precious metals are stamped and pressed in iron molds, and filamentary precious metals are made by drawing in iron molds, so the surface is smooth and shiny, and there is no need to use files for trimming, which avoids the loss of precious metals during the trimming process.

[0014] This technique is used in jewelry such as bracelets, necklaces, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com