Low-silver brazing filler metal for welding pure silver jewelry and preparation method of low-silver brazing filler metal

A technology of silver solder and jewelry, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as turbulence and air holes that are prone to occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

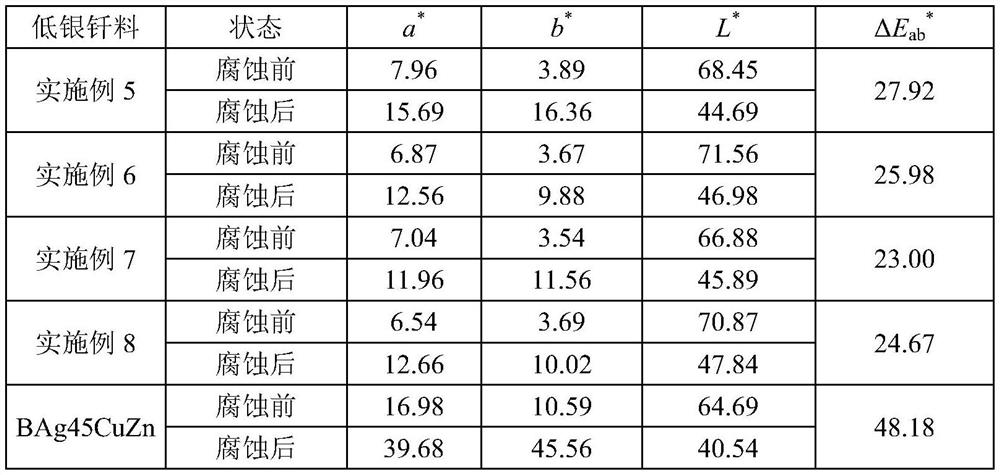

Examples

Embodiment 1

[0047] The low-silver brazing filler metal of the present embodiment is made up of the following elements by mass percent: Ag 60%, Zn 10%, Sn 2%, Si 0.4%, Ge 0.4%, Ce 0.02%, balance is Cu.

Embodiment 2

[0049] The pure silver jewelry soldering of the present embodiment is made up of the following elements of mass percent: Ag 65%, Zn 12%, Sn 1%, Si 0.3%, Ge 0.5%, Pd 0.8%, Ni 0.8%, balance For Cu.

Embodiment 3

[0051] The pure silver jewelry soldering of the present embodiment is made up of the following elements of mass percent: Ag 70%, Zn 15%, Sn 4%, Si 0.5%, Ge 0.3%, Pt 0.5%, Ir 0.3%, Co 0.4 %, the balance is Cu.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com