Preparation method of anti-ultraviolet card protecting film

An anti-ultraviolet and anti-card film technology, which is applied in the field of preparation of anti-ultraviolet protective film, can solve the problem of poor tensile, waterproof, fireproof, insulation and corrosion resistance, reduced service life of the protective film, and anti-corrosion properties of the protective film. Problems such as weak UV ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

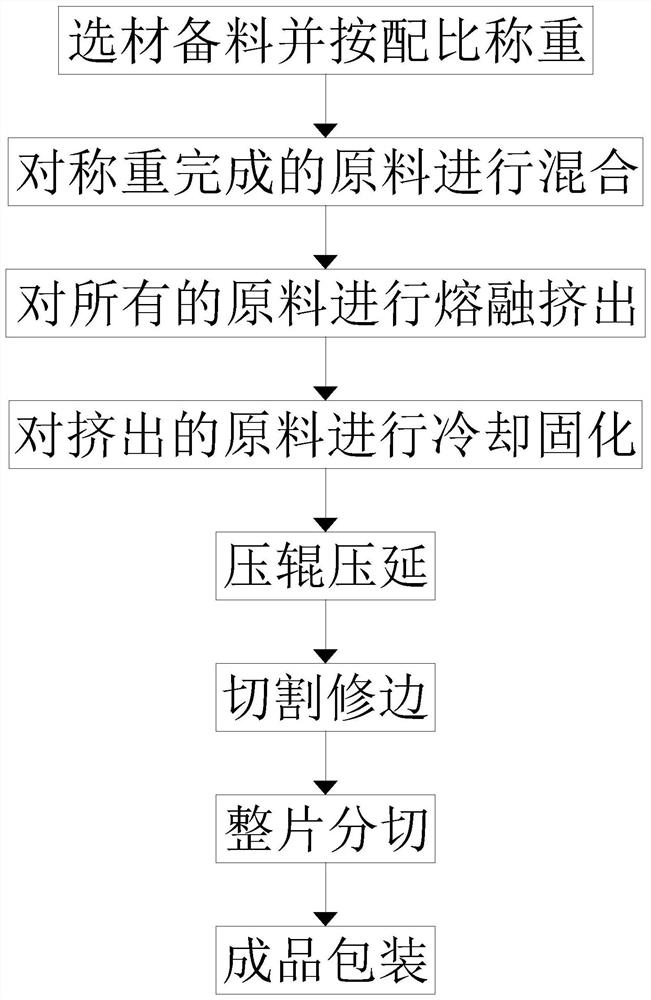

[0029] see figure 1 , the present invention provides a technical solution: a method for preparing an anti-ultraviolet protective card film, comprising the following steps:

[0030] S1: Prepare the raw materials for the preparation of the anti-ultraviolet card film, use the washing machine to clean the raw materials for the preparation of the card film, use the oven to quickly dry all the raw materials, and then use the weighing scale to dry the different raw materials Load-bearing according to the ratio, and stored on the storage rack in turn, the main components of the raw materials for the preparation of the anti-ultraviolet household card film in the step S1 include 5-9 parts of polyethylene terephthalate, 2-4 parts of nano-titanium dioxide, 6-9 parts of polyester cellulose, 10-20 parts of epoxy resin, 2-4 parts of toughening agent, 3-4 parts of dispersant, 3-6 parts of flame retardant, 0.2-0.9 parts of antioxidant, corrosion resistance 5-6 parts of agent, 0.1-9 parts of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com