Novel cold storage board

A cold storage board, a new technology, applied in the field of boards, can solve the problems of poor thermal insulation effect, poor air tightness, poor flame retardancy, etc., and achieve good insulation layer thickness, strong overall tensile strength, and fire prevention effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

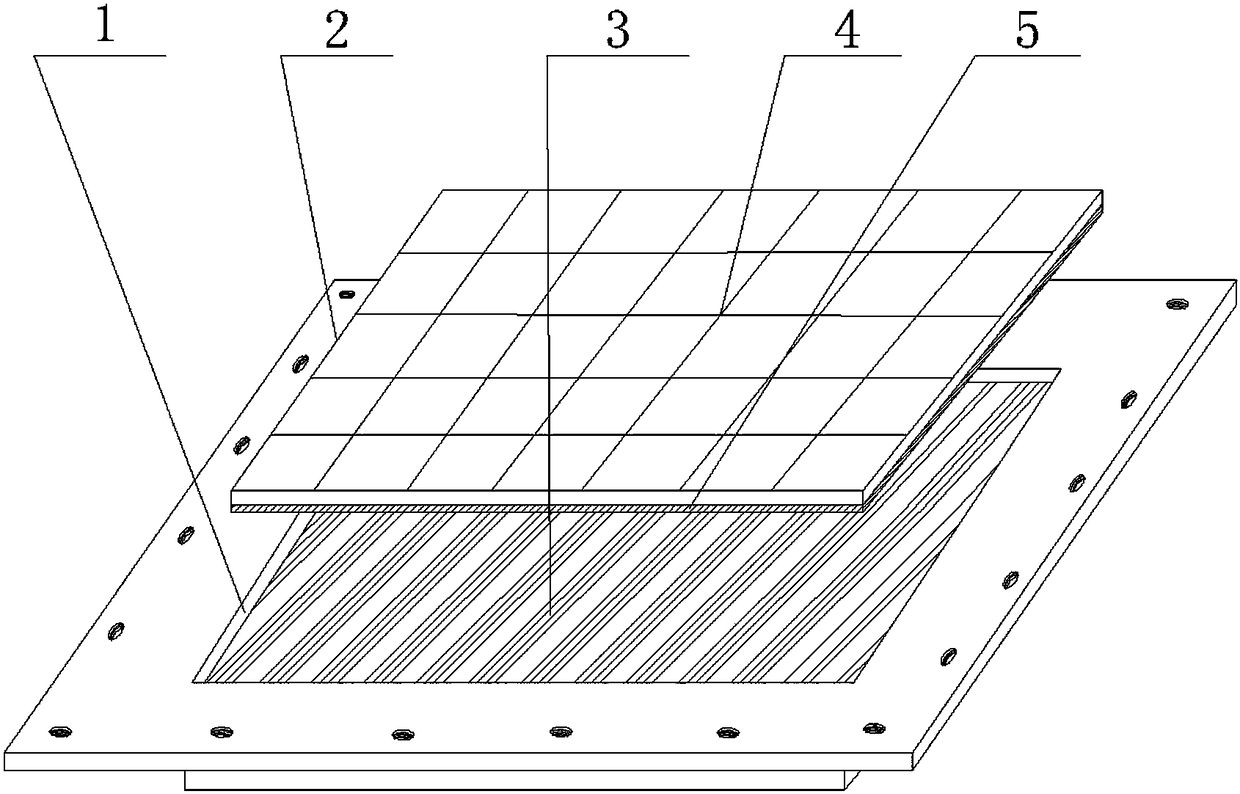

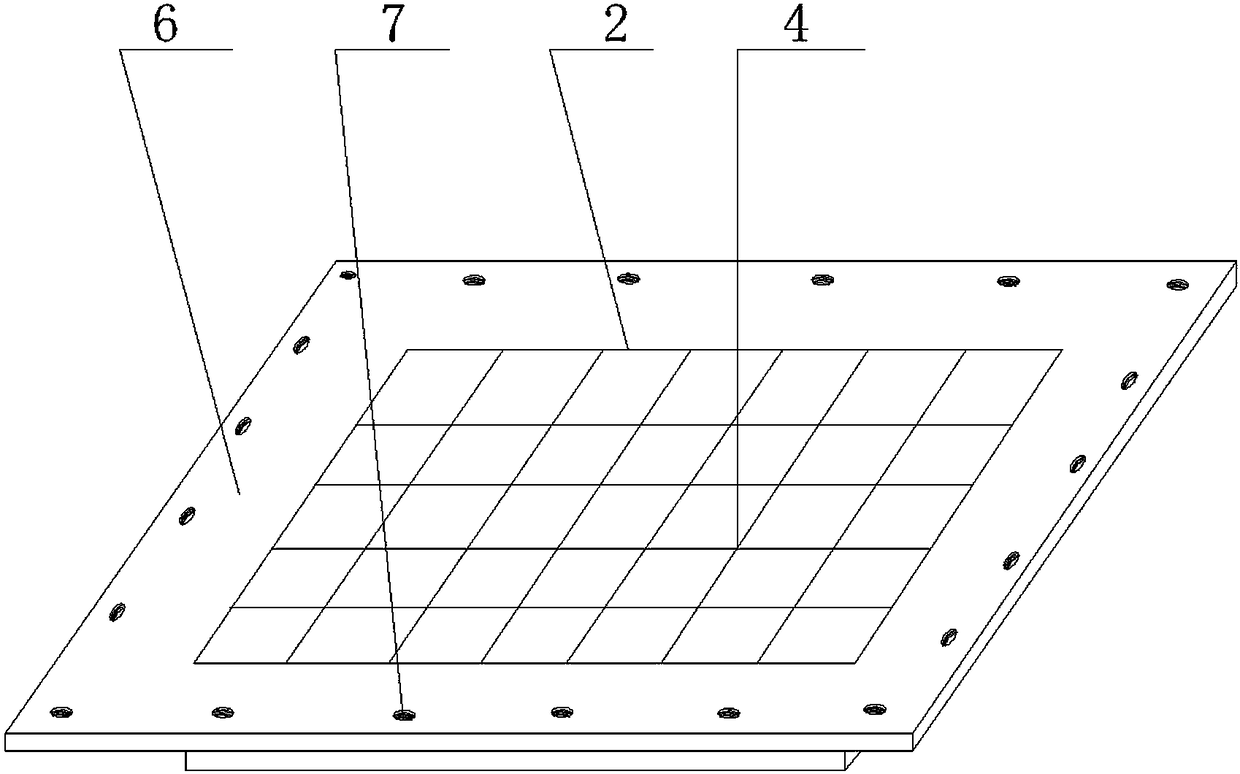

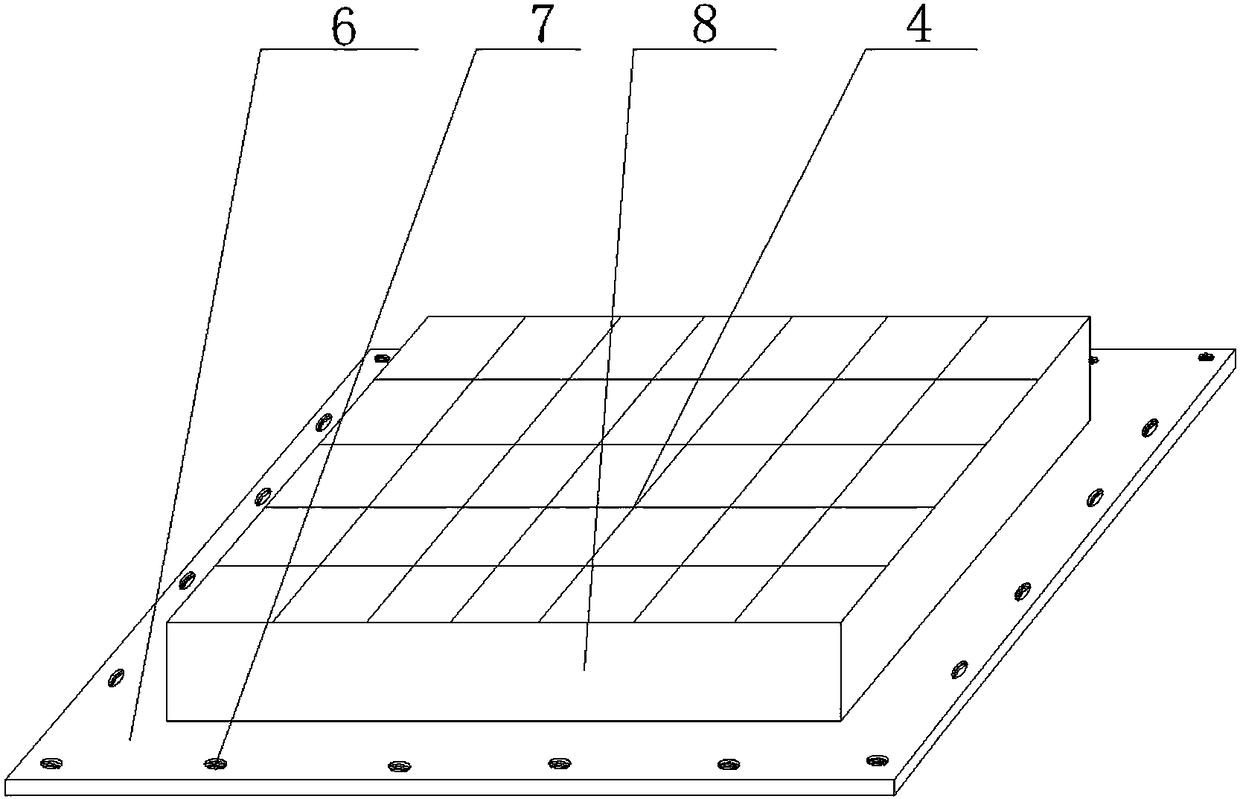

[0019] combined with Figures 1 to 4 As shown, a novel cold storage panel of the present invention is characterized in that: the cold storage panel includes a box-shaped panel 8, the upper part of the box-shaped panel 8 is an opening 1, and the opening 1 is covered with a sealing panel 2. The size of the opening 1 corresponds to the size of the sealing panel 2, the sealing panel 2 is sealed and connected with the box-shaped panel 8, and the periphery of the box-shaped panel 8 is provided with a wing edge 6; the sealing A layer of vacuum insulation panels 5 is provided on the lower surface of the panel 2, a layer of vacuum insulation panels 5 is provided on the inner bottom surface of the box-shaped panel 8, and a filler is provided between the two layers of vacuum insulation panels 5 inside the box-shaped panel 8. layer 3, the filler layer 3 is a rock wool insulation layer; between the lower surface of the sealing panel 2 and the vacuum insulation panel 5, between the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com