Low-yield-ratio thin-gauge high-strength and acid-resistant pipeline steel hot rolled coil plate and manufacturing method thereof

A low yield ratio and manufacturing method technology, applied in the field of pipeline steel manufacturing, can solve problems such as hydrogen cracking, poor economy, difficult control of yield ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

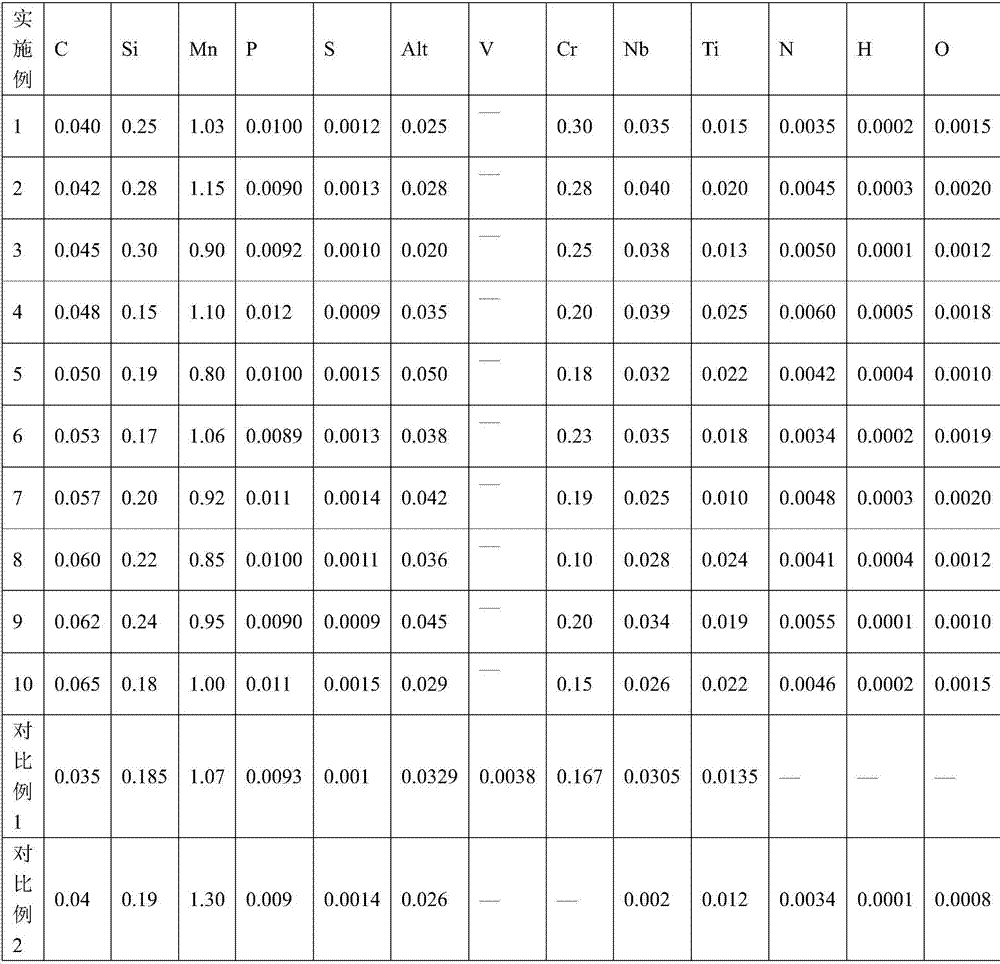

Embodiment 1~10

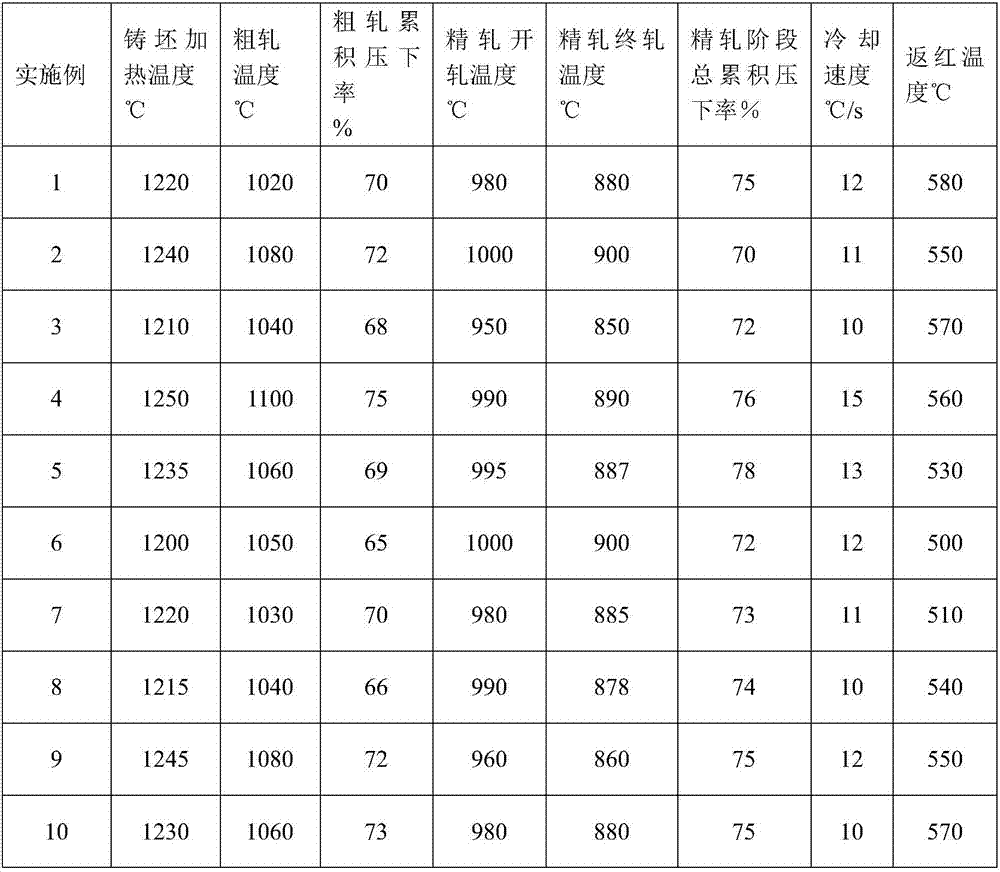

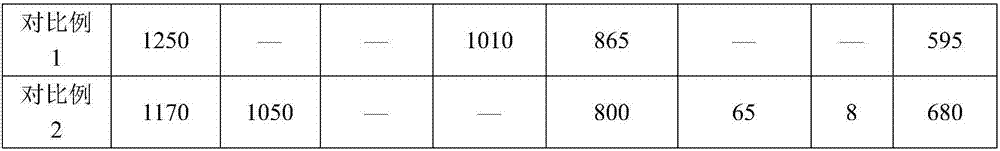

[0044] Embodiment 1 to Embodiment 10 of the present invention are produced in accordance with the following method, and the specific process parameters are shown in Table 2:

[0045] 1) It is smelted by converter-LF furnace-vacuum furnace and cast into billets. Among them, the vacuum treatment time is not less than 15 minutes.

[0046] 2) After slow cooling for 24 hours, install the furnace and reheat to 1150-1250°C, and the total time in the furnace is 140-160 minutes.

[0047] 3) Rough rolling is carried out, the rolling temperature is controlled at 1020-1100°C, and the cumulative reduction rate in the rough rolling stage is ≥65%.

[0048] 4) Carry out finish rolling, the starting rolling temperature is controlled at 950-1000°C, the final rolling temperature is controlled at 850-900°C, and the cumulative rolling reduction rate is ≥70%.

[0049] 5) Cooling: Control the temperature of starting and cooling at 810-850°C, control the temperature of turning red at 500-580°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com