Preparation method of deep and narrow gap gas metal arc welding contact tube

A technology of molten electrode gas and shielded welding, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc. It can solve the problems of difficult coating, influence of welding stability, shedding or cracking, etc., so as to improve the resistance to friction and wear And high temperature resistance, optimized working environment, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

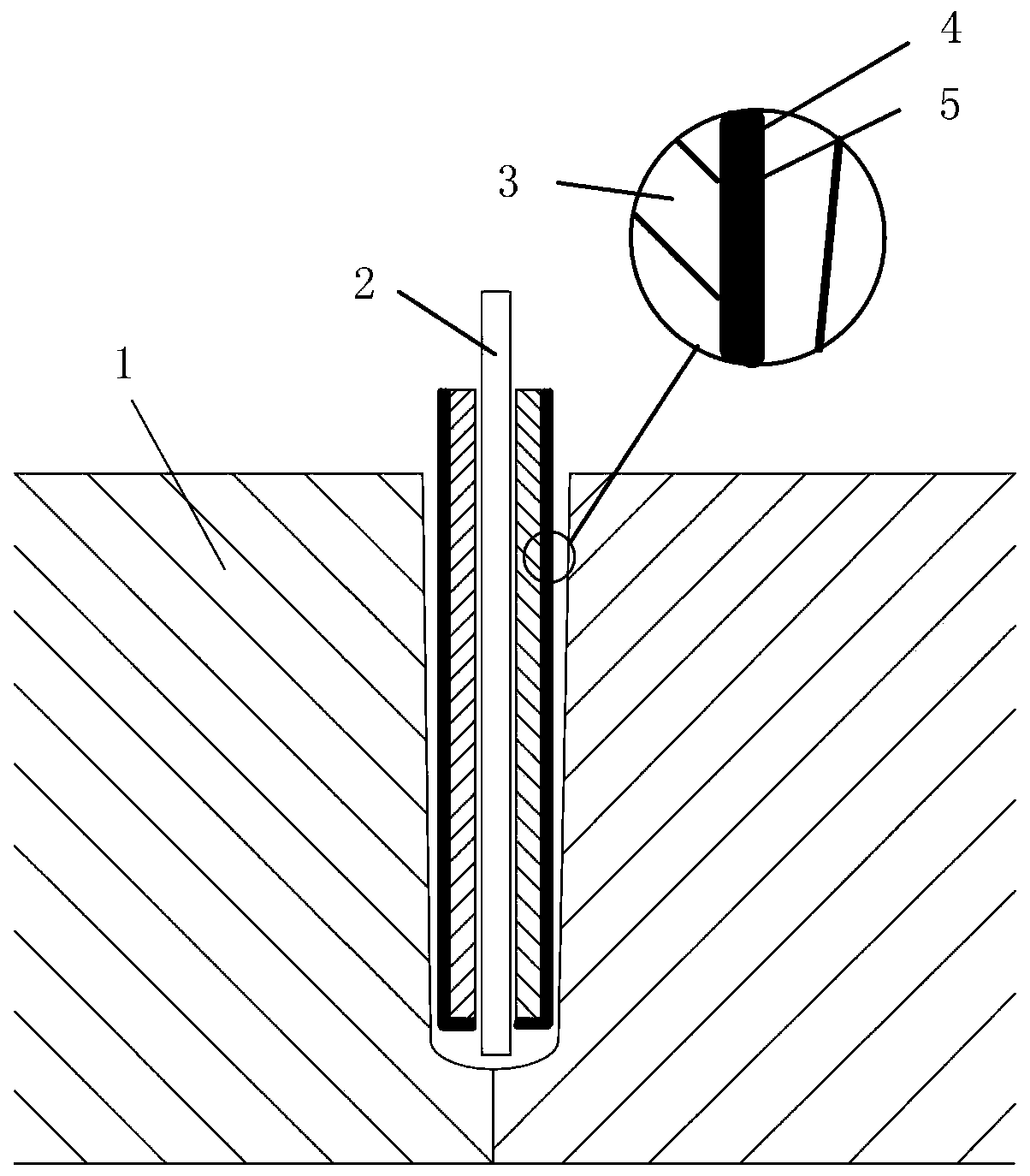

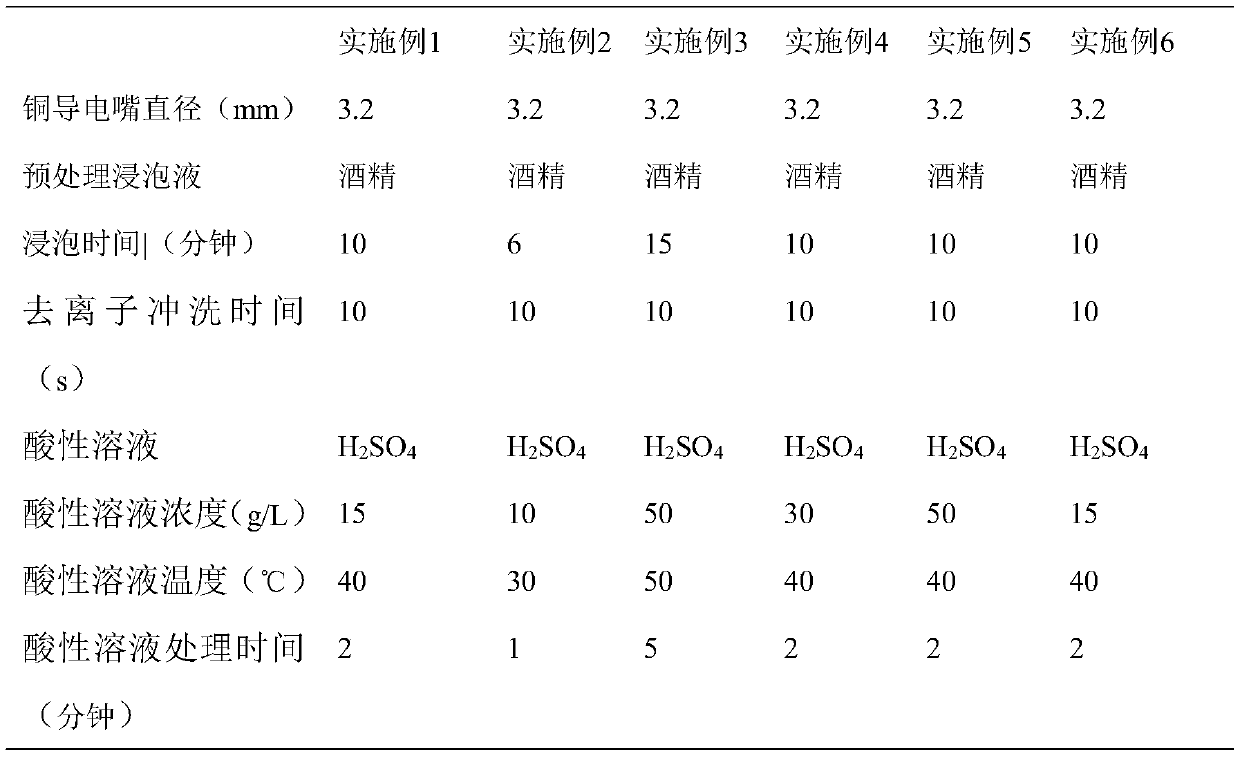

[0033] 1) A solid copper contact tip matched with a narrow gap groove weld is obtained by machining, and the present invention can coat a copper contact tip with a diameter of 3.2 mm with an alumina coating.

[0034] 2) The copper contact tip in step 1) is treated with solvent hot-dip aluminizing:

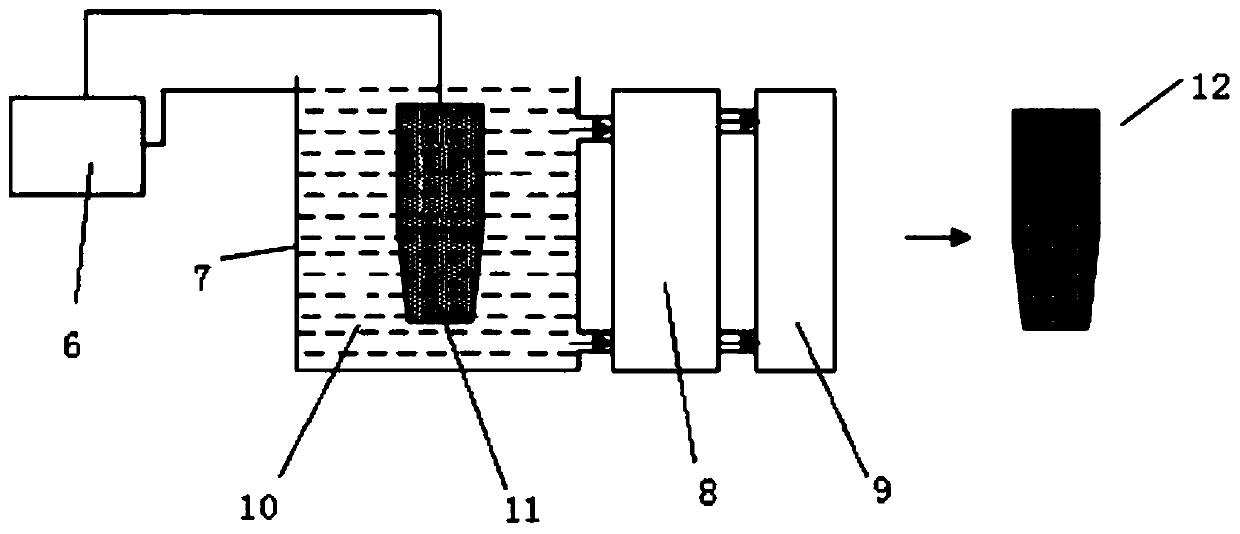

[0035] First polish the copper surface with sandpaper until bright, then clean it with deionized water, then soak the copper surface in alcohol for 10 minutes, then clean it with deionized water, and finally, immerse the copper surface in 40℃, 15g / L H 2 SO 4 In the solution for 2 minutes, then quickly rinsed with deionized water; and placed in a 80 ℃, 3% KF plating flux solution for 3 minutes, then taken out and quickly dried, after holding for a certain period of time, immersed in molten aluminum, hot dipping The plating temperature is about 700 ℃, and the hot dip plating time is 8s, so that the copper surface is coated with a sealing aluminum layer with a thickness of about 10 μ...

Embodiment 2

[0041] 1) A solid copper contact tip matched with a narrow gap groove weld is obtained by machining, and the present invention can coat a copper contact tip with a diameter of 3.2 mm with an alumina coating.

[0042] 2) The copper contact tip in step 1) is treated with solvent hot-dip aluminizing:

[0043] First polish the copper surface with sandpaper until it is bright, then clean it with deionized water, then soak the copper surface in alcohol for 6 minutes, rinse it with deionized water for 10s, and finally, immerse the copper surface in 30℃, 10g / L H 2 SO 4 In the solution for 1 minute, then quickly rinsed with deionized water; and put it in a 70 ° C, 1% KF plating flux solution for 1 minute, then taken out and quickly dried, after holding for a certain period of time, immersed in molten aluminum, hot dipping The plating temperature is about 660 ℃, and the hot dip plating time is 6s, so that the copper surface is coated with a sealing aluminum layer with a thickness of ab...

Embodiment 3

[0049] 1) A solid copper contact tip matched with a narrow gap groove weld is obtained by machining, and the present invention can coat a copper contact tip with a diameter of 3.2 mm with an alumina coating.

[0050] 2) The copper contact tip in step 1) is treated with solvent hot-dip aluminizing:

[0051] First polish the copper surface with sandpaper until it is bright, then clean it with deionized water, then soak the copper surface in alcohol for 15 minutes, rinse it with deionized water for 10s, and finally, immerse the copper surface in 50℃, 50g / L H 2 SO 4 In the solution for 5 minutes, then quickly rinsed with deionized water; and placed in a 80 ℃, 10% KF plating flux solution for 5 minutes, then taken out and quickly dried, after holding for a certain period of time, immersed in molten aluminum, hot dipping The plating temperature is about 750 ℃, and the hot dip plating time is 30s, so that the copper surface is coated with a sealing aluminum layer with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com