Cubic boron nitride self-lubricating coated tool and preparation method thereof

A technology of cubic boron nitride and self-lubricating coating, which is applied in coating, metal material coating technology, etc., can solve the problem of insufficient bonding strength between coating and substrate, limitation of coating thickness on tool surface, and non-self-lubricating coating Efficacy and other issues, to achieve good self-lubricating effect, strong bonding strength, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

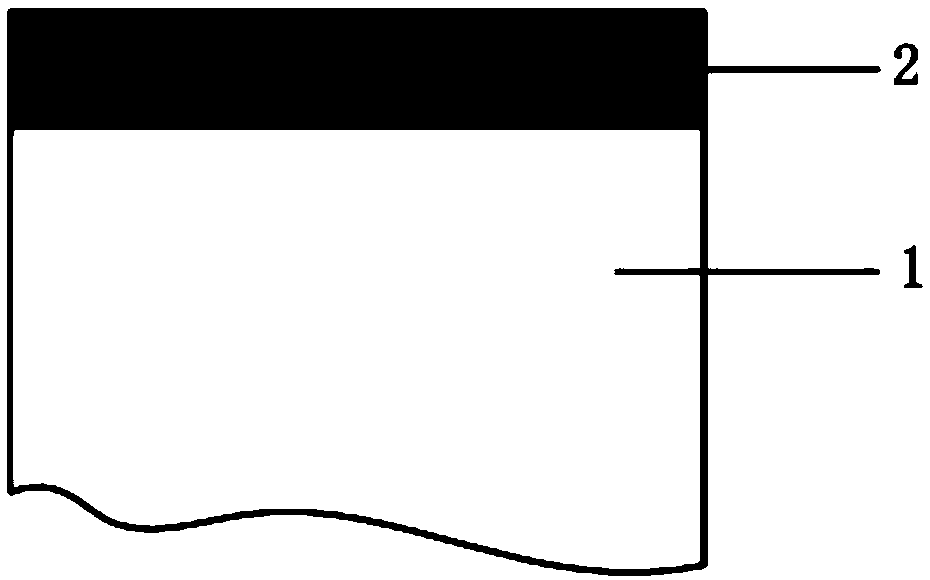

[0018] A cubic boron nitride self-lubricating coating tool, the material of the tool substrate 1 is cemented carbide, and the surface of the substrate 1 has a cubic boron nitride self-lubricating coating 2, wherein the coating contains CsF, Mo and ZrO 2 .

[0019] A method for preparing a cubic boron nitride self-lubricating coating cutter, wherein the cubic boron nitride self-lubricating coating is prepared on the rake face of a cutter substrate by electron beam cladding technology, and the specific preparation steps are:

[0020] (1) Pretreatment: Grind the surface of the tool substrate and place it in alcohol and acetone solutions for ultrasonic cleaning for 20 minutes each to degrease.

[0021] (2) Pre-set boron nitride layer: configure cubic boron nitride mixed powder, the weight percentage of each component is: 55% CBN, 20% Ni, 8% CsF, 8% Mo and 9% ZrO2; Add it into the mixed powder to form a thick shape and pre-place it on the rake face of the tool base. Use the method...

Embodiment 2

[0025] A cubic boron nitride self-lubricating coating tool, the material of the tool substrate 1 is high-speed steel, and the surface of the substrate 1 has a cubic boron nitride self-lubricating coating 2, wherein the coating contains CsF, Mo and ZrO 2 .

[0026] A method for preparing a cubic boron nitride self-lubricating coating cutter, wherein the cubic boron nitride self-lubricating coating is prepared on the rake face of a cutter substrate by electron beam cladding technology, and the specific preparation steps are:

[0027] (1) Pretreatment: Grind the surface of the tool substrate and place it in alcohol and acetone solutions for ultrasonic cleaning for 30 minutes each to degrease.

[0028] (2) Pre-set boron nitride layer: configure cubic boron nitride mixed powder, the weight percentage of each component is: 65% CBN, 18% Ni, 6% CsF, 6% Mo and 5% ZrO2; Add it into the mixed powder to form a thick shape and pre-place it on the rake face of the tool base, and keep it fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com