A preparation method of a deep narrow gap melting electrode gas shielded welding contact tip

一种熔化极气体、保护焊接的技术,应用在电解涂料、阳极氧化、表面反应电解涂层等方向,能够解决涂层难度大、焊接稳定性影响、坡口宽度增加等问题,达到提高抗摩擦磨损及耐高温性能、优化工作环境的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

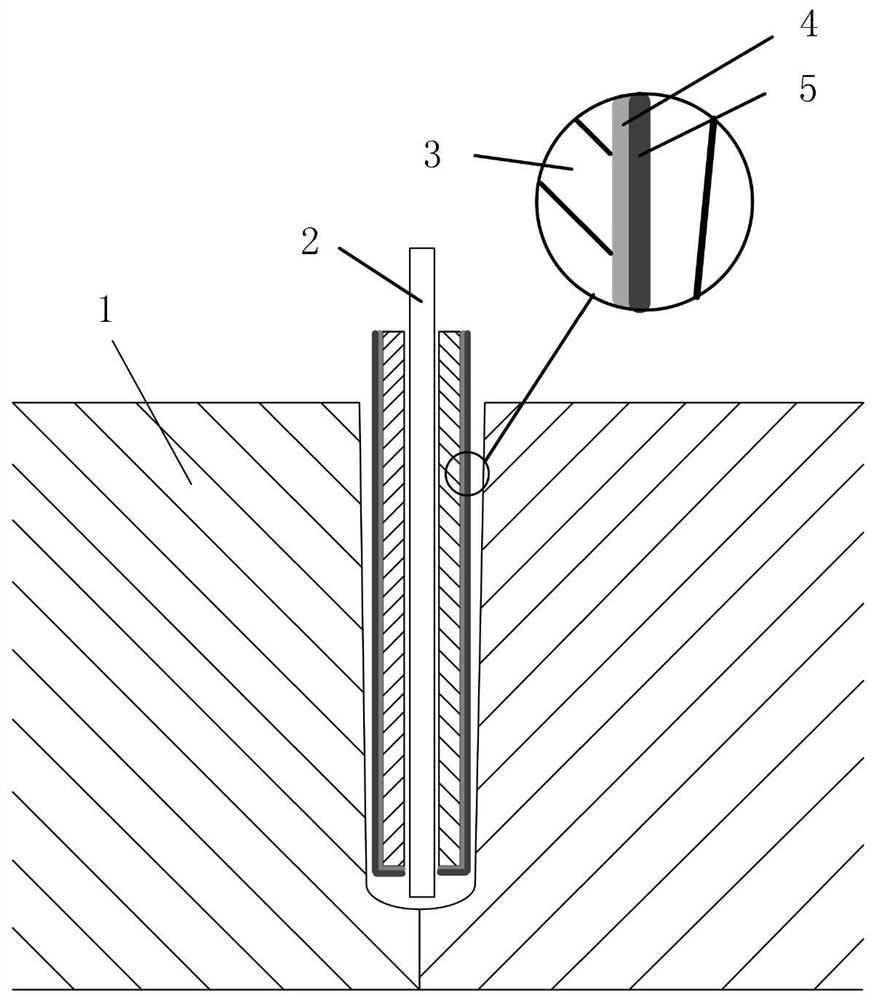

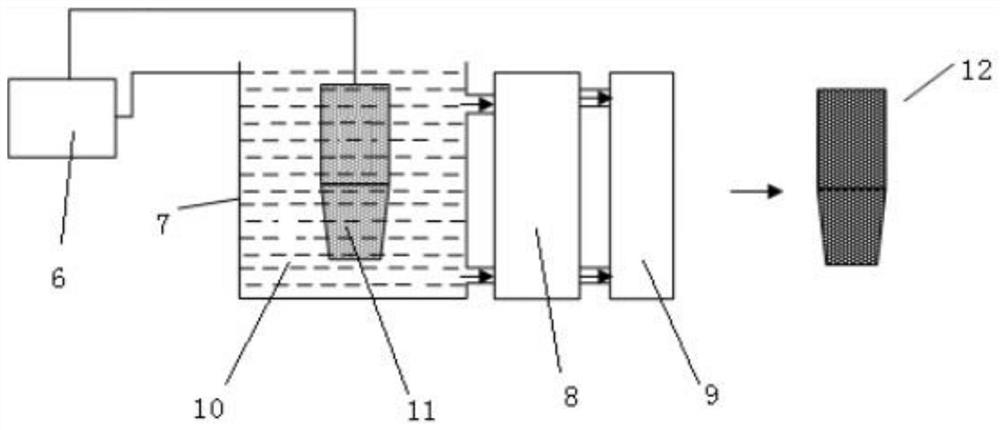

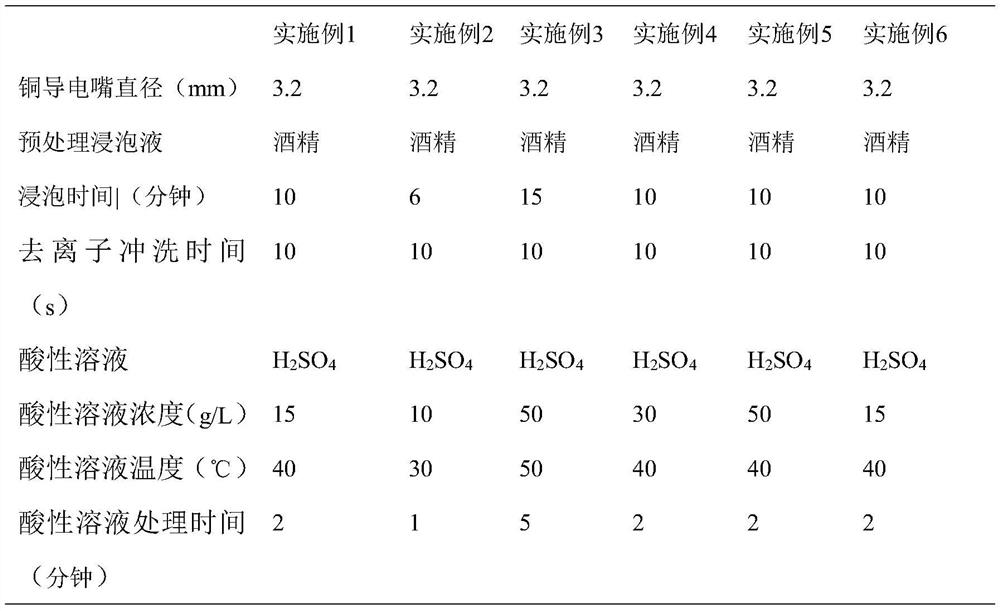

[0033] 1) A solid copper contact tip matching a narrow gap groove weld is obtained by mechanical processing, and the present invention can plate an aluminum oxide coating on a copper contact tip with a diameter of 3.2mm.

[0034] 2) The copper contact tip in step 1) is treated by solvent hot-dip aluminum plating:

[0035] First polish the copper surface with sandpaper until it is bright, then clean it with deionized water, then soak the copper surface with alcohol for 10 minutes, then clean it with deionized water, and finally, immerse the copper surface in 40°C, 15g / L H 2 SO 4 solution for 2 minutes, then quickly rinse with deionized water; and put in 80 ° C, 3% KF flux solution for 3 minutes, then take it out and quickly dry it, keep it warm for a certain period of time, immerse it in molten aluminum, hot dip The plating temperature is about 700°C, and the hot-dip plating time is 8s, so that the copper surface is coated with a sealed aluminum layer with a thickness of about...

Embodiment 2

[0041] 1) A solid copper contact tip matching a narrow gap groove weld is obtained by mechanical processing, and the present invention can plate an aluminum oxide coating on a copper contact tip with a diameter of 3.2mm.

[0042] 2) The copper contact tip in step 1) is treated by solvent hot-dip aluminum plating:

[0043] First polish the copper surface with sandpaper until it is bright, then clean it with deionized water, then soak the copper surface with alcohol for 6 minutes, rinse it with deionized water for 10 seconds, and finally, immerse the copper surface in 30°C, 10g / L H 2 SO 4 Put it in the solution for 1 minute, then quickly rinse it with deionized water; put it into the 70°C, 1% KF flux solution for 1 minute, then take it out and dry it quickly, after holding it for a certain period of time, immerse it in molten aluminum, hot dip The plating temperature is about 660°C, and the hot-dip plating time is 6s, so that the copper surface is coated with a sealed aluminum ...

Embodiment 3

[0049] 1) A solid copper contact tip matching a narrow gap groove weld is obtained by mechanical processing, and the present invention can plate an aluminum oxide coating on a copper contact tip with a diameter of 3.2mm.

[0050] 2) The copper contact tip in step 1) is treated by solvent hot-dip aluminum plating:

[0051] First polish the copper surface with sandpaper until it is bright, then clean it with deionized water, then soak the copper surface with alcohol for 15 minutes, rinse it with deionized water for 10 seconds, and finally immerse the copper surface in 50°C, 50g / L H 2 SO 4 solution for 5 minutes, then quickly rinse with deionized water; and put it in 80 ℃, 10% KF flux solution for 5 minutes, then take it out and dry it quickly, after holding it for a certain period of time, immerse it in molten aluminum, hot dip The plating temperature is about 750°C, and the hot-dip plating time is 30s, so that the copper surface is coated with a layer of sealed aluminum layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com