Semi-steel UTV tire

A technology for tires and treads, applied in tire parts, tire treads/tread patterns, tire sidewalls, etc. Acceleration performance and agility, small loss of rigidity, and enhanced grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

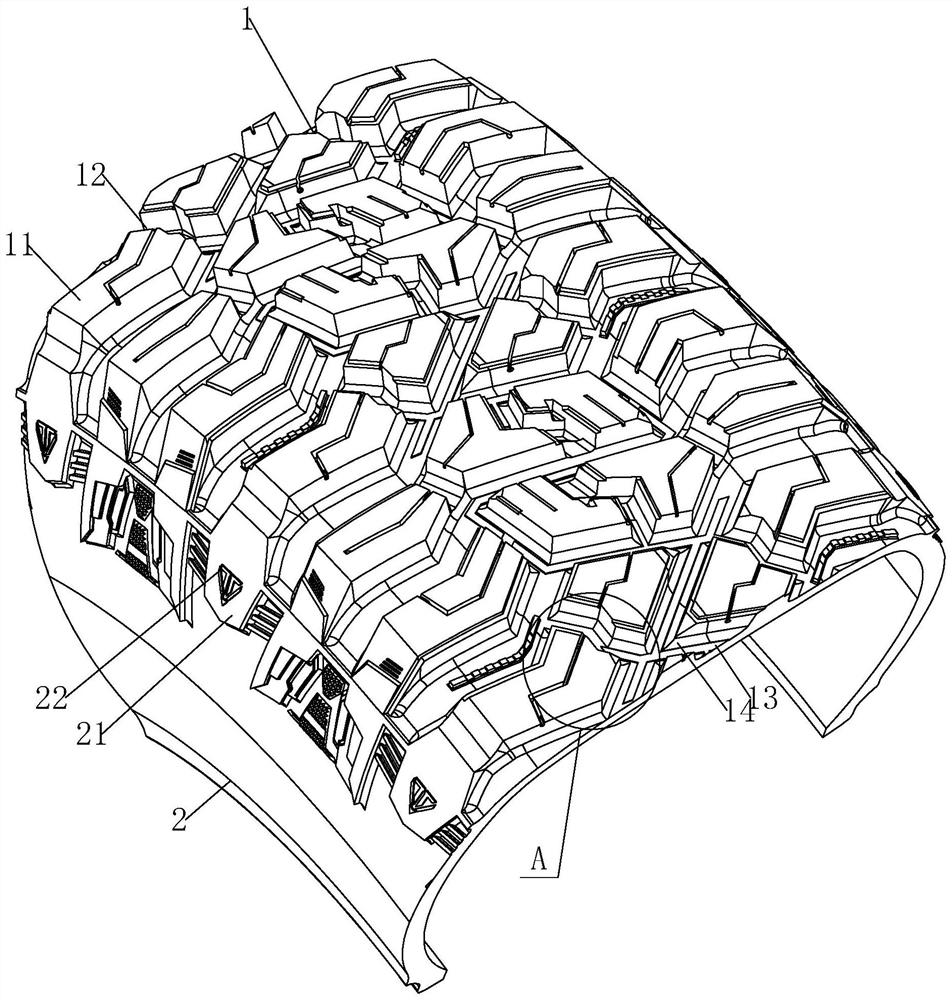

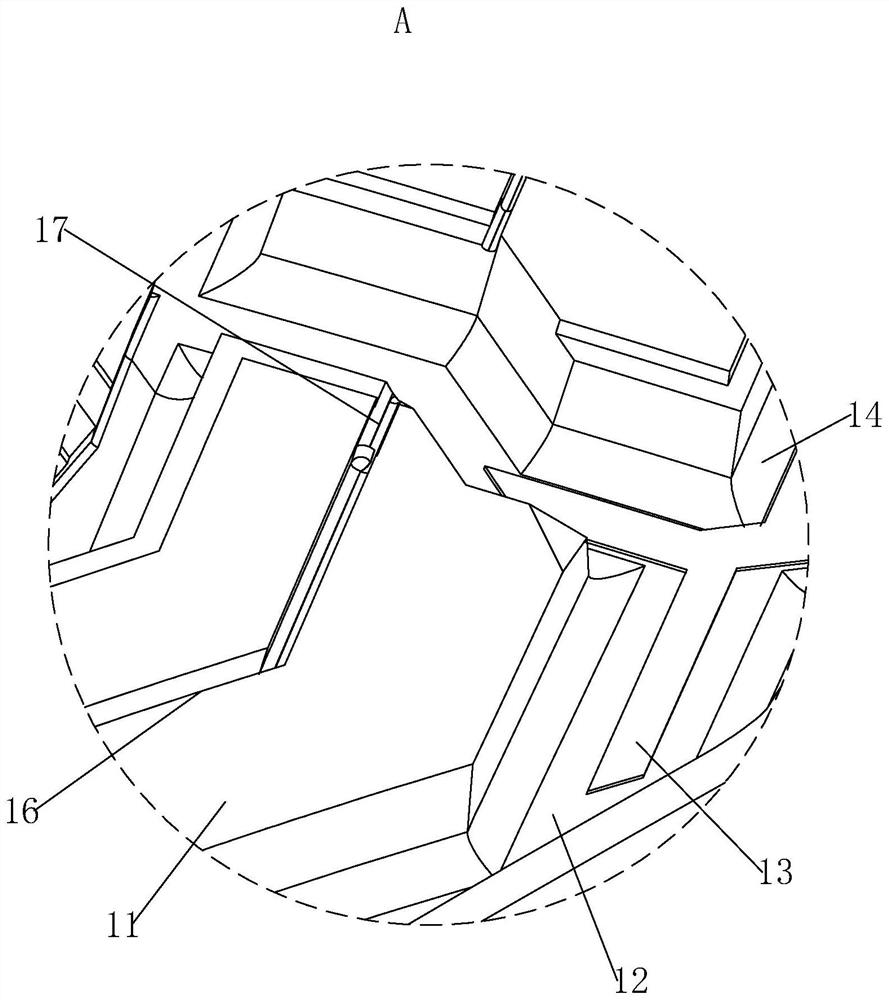

[0042] Example 1: A semi -steel UTV tire, refer to figure 1 Including the tire 1 on the outer layer and the tire side 2, the surface of the tire 1 is set with irregular pattern block 11, adjacent pattern block 11 is separated by groove 12, grooves 12 of the groove 12 The depth is 35 ± 5mm, and the width of the groove 12 gradually decreases from the top to the bottom. The bottom of the groove 12 along the groove 12 direction of the trench 12, the anti -thorn bar 13 is protruded on the bottom surface of the groove 12, The position 12 of the groove 12 of the tire structure with a weak tire structure is strengthened to improve the anti -thorns performance.

[0043]Anti -Stabbing 13 can be processed with the tire 1 and patterned block 11. It can also be supplemented in the groove 12 and uses the same materials as the tire 1. 1 The position of the surface is close to the central axis. The position of the center of the tire 1 is the main contact area of the tire and the ground, and it ...

Embodiment 2

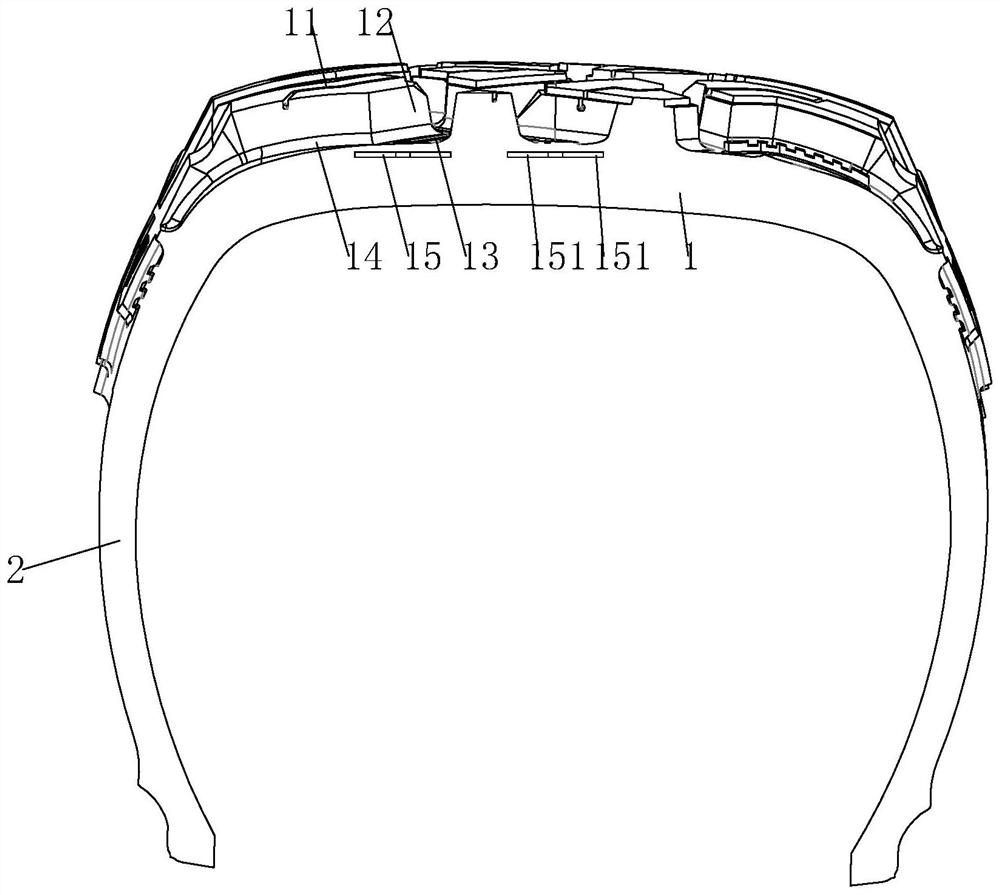

[0050] Example 2: A semi -steel UTV tire, refer to image 3 There is a metal enhanced rack 15 in the structure of the tire 1, and the direction of the metal enhanced rack 15 along the groove 12 of the groove 12, which is concentrated in the lower layer of the thorns 13 to supplement the lower structure of the thorns 13 12 bottom of the bottom. The metal reinforcement rack 15 uses a strong metal material with strong toughness, and the physical width of the metal enhanced frame 15 is greater than the width of the anti -spines 13, and the two sides exceed the sides of the Anti -Stabbing strip 13.

[0051] When UTV tires encounter small -size sharp objects entering the groove 12, sharp objects are likely to pierce the anti -thorn bar 13, but it will be blocked by strengthening metal frames. Protecting the internal tires of the car is not pierced.

[0052] In order to facilitate the processing of the metal enhanced frame 15 in the tire 1, the metal enhanced frame 15 adopts a segmented s...

Embodiment 3

[0054] Example 3: A semi -steel UTV tire, refer to Figure 4 The difference between the embodiments and the embodiment 2 is that the metal enhanced frame 15 points into the upper and lower layers. From the perspective of the section structure, the two parallel metal strips 151 are at different heights. Overlap, and the two metal strips 151 have a gap between 1 rubber filling. The width of the metal bar 151 in this embodiment is less than the width of the groove 12, and the same thickness does not exceed 2mm.

[0055] After the sharp object is assassinated by the thorns 13, there will also be two cases: one is that it will be exposed to the first layer of metal bar 151, and the first layer of metal bar 151 will continue to squeeze down the second metal bar 151 , And blocked by two layers of metal strips 151; another situation is that after the first layer of metal bar 151 is pierced, it cannot continue to squeeze downwards, slide on both sides, and be guided into the pattern block 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com