Tubular beam of torsion beam axle type suspension

A technology of torsion beam suspension and tube beam, applied in suspension, elastic suspension, interconnection system, etc., can solve the problem of difficulty in finding simultaneous requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

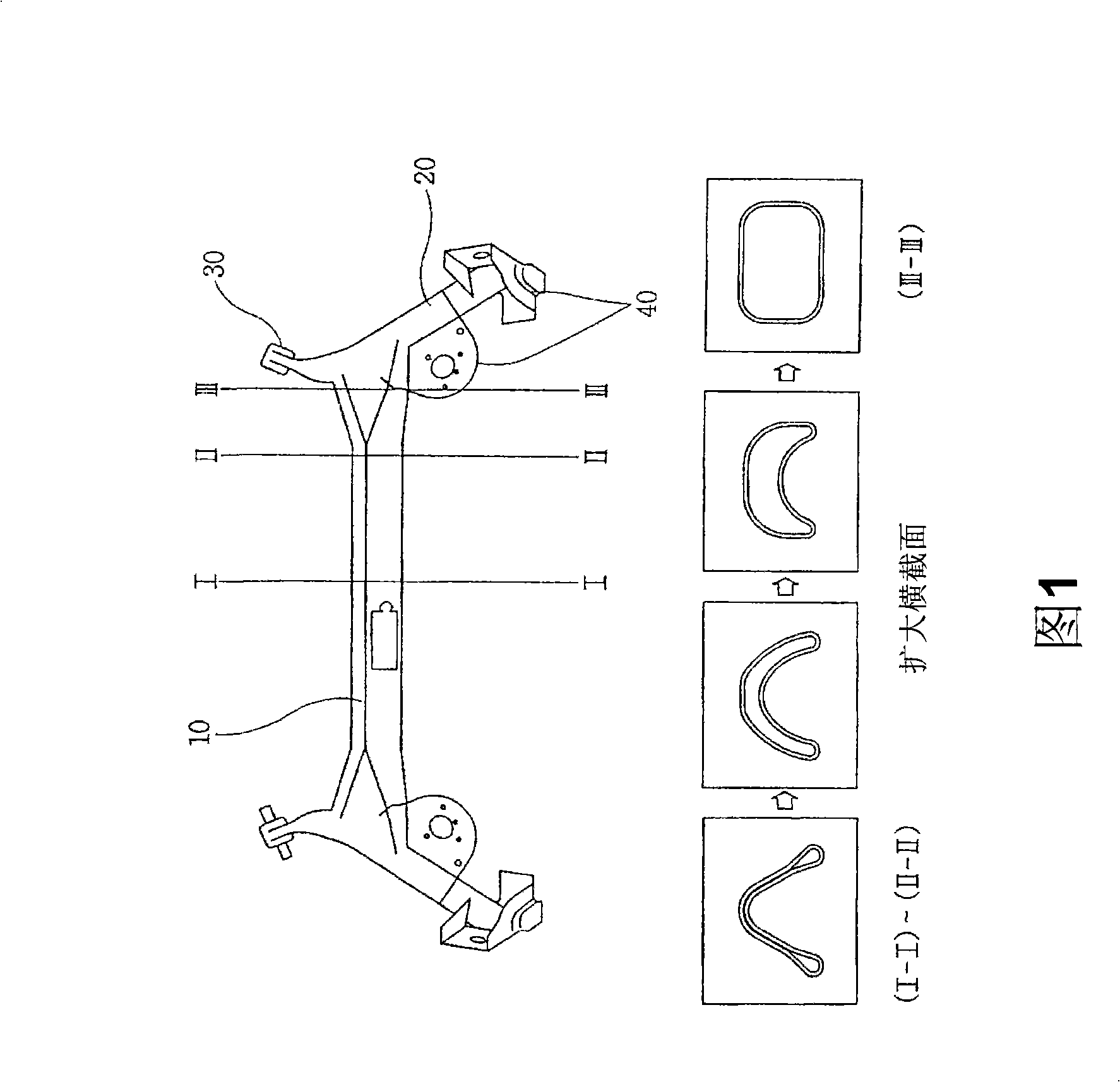

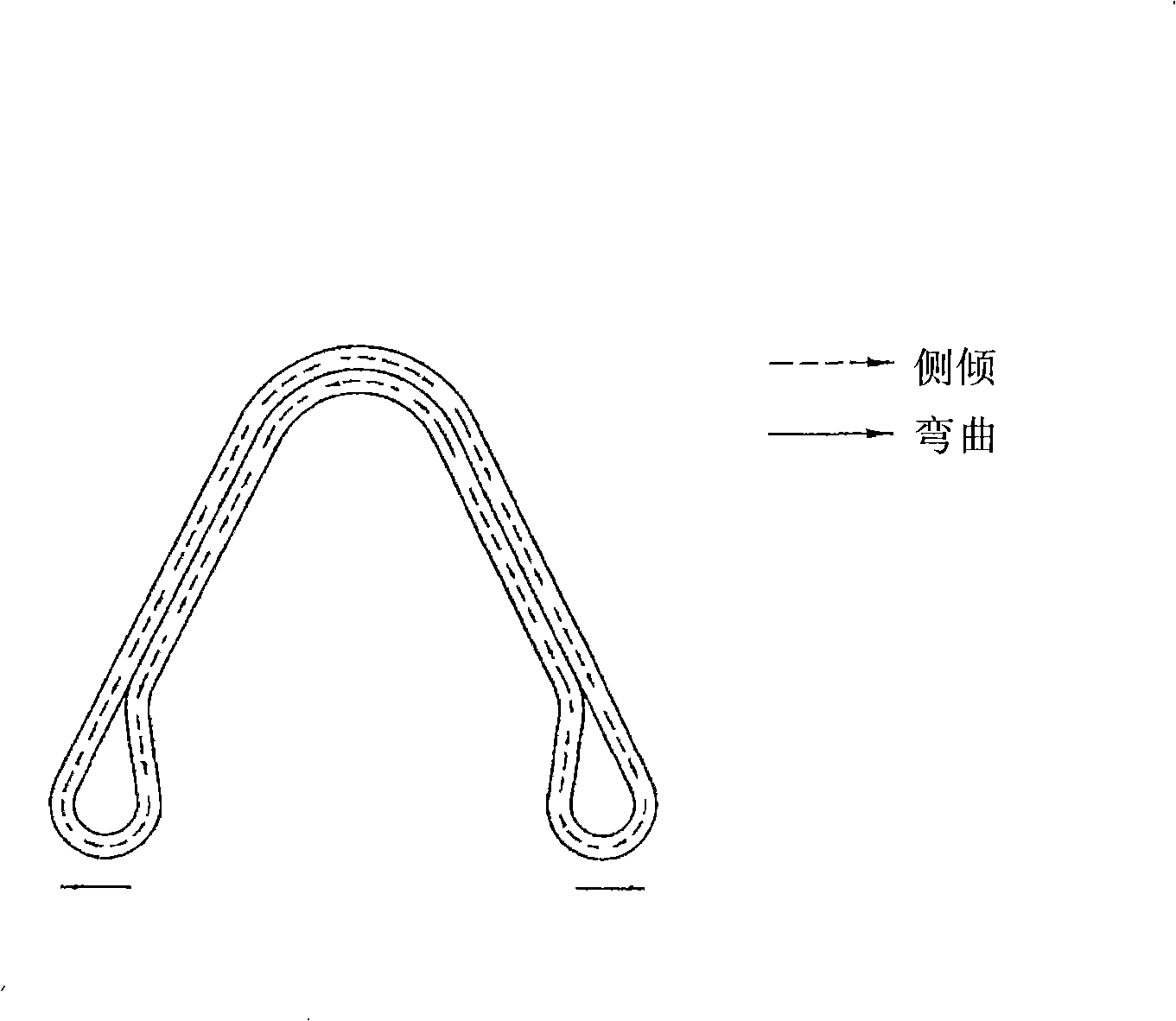

[0030] A preferred embodiment of the present invention will be described below with reference to FIG. 6 .

[0031] A parent tube of a tube beam having a diameter of 101.6 mm and a thickness of 2.8 mm is described by way of example in this embodiment.

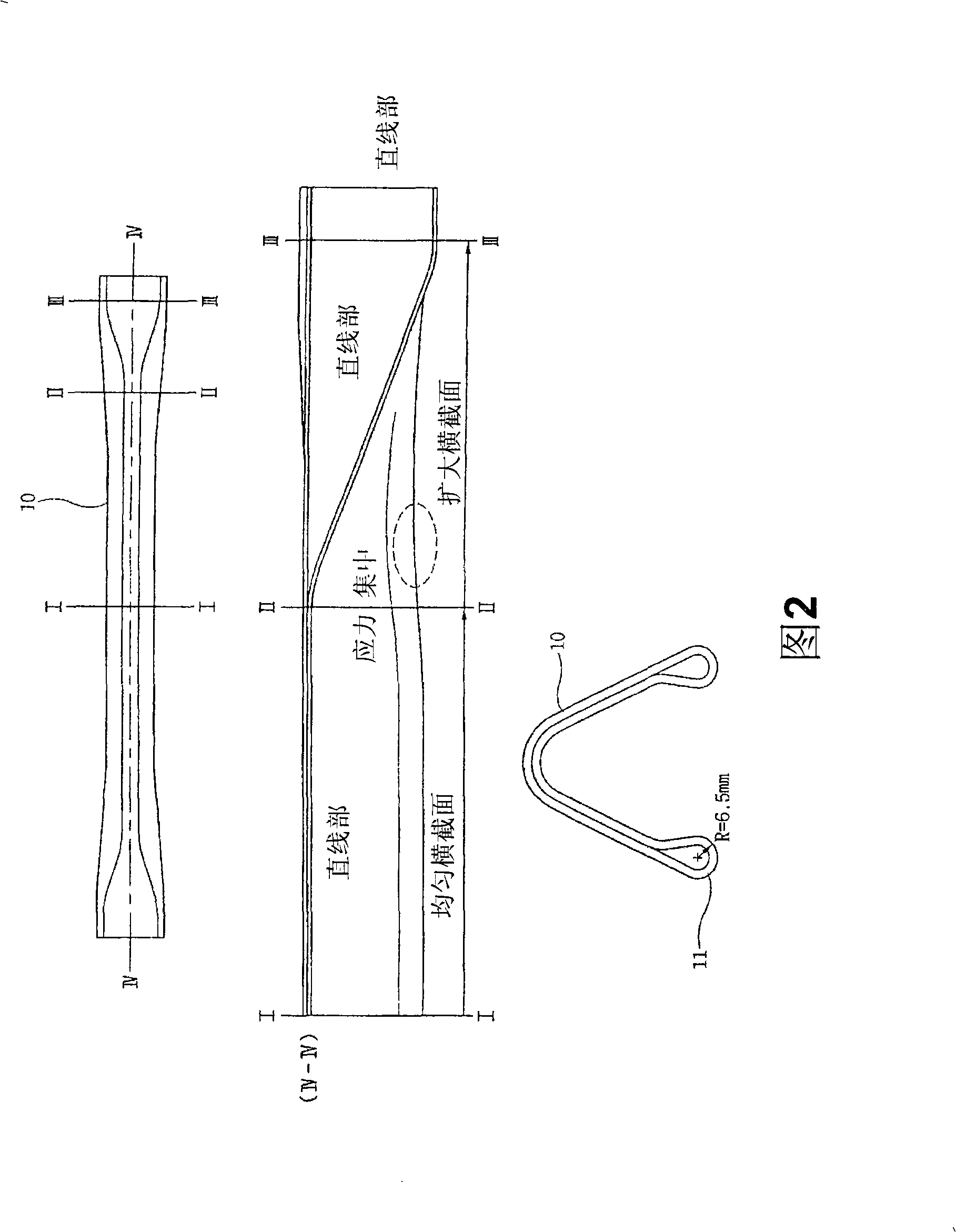

[0032] In related prior art, for tubes of the same size, the tube beam is made with a tail radius R of 6.5 mm (the part from line I-I to line II-II), and then enlarged (from line II-II to line III -Part of line III).

[0033] Furthermore, in the related prior art, the tail radius R and the cross-sectional width are equal except for the enlarged portions (portions from II-II line to III-III line) at both ends of the pipe beam. Since the width of the cross section on this part is constant, the center of shear is also constant.

[0034] On the other hand, in this embodiment of the invention, the uniform cross-sectional portion of the middle portion (the portion from line A-A to line B-B) is formed to have a tail radius R1 of 5 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com