Cast-in-place concrete pile with expanded-diameter threaded pile section, drill bit device for pile forming and pile forming method

A technology for concrete and cast-in-place piles, which is applied to drill bits, earthwork drilling, sheet pile walls, etc., can solve the problems of insufficient use of pile bottom soil stress, many human factors in the reinforcement of original soil layers, and large differences in reinforcement results. Achieve the effect of saving pile material, increasing the effective circumferential area, and strong pull-out ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

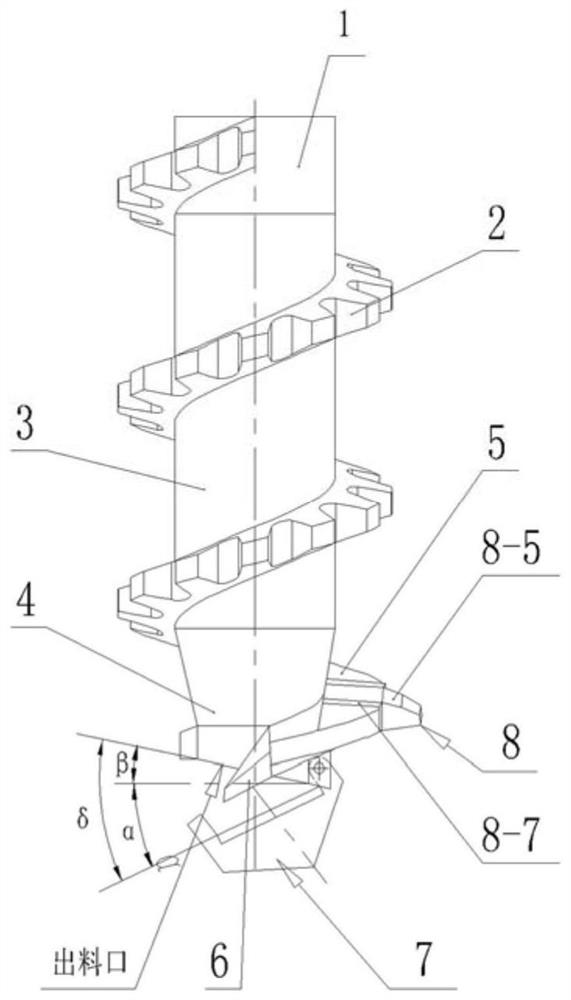

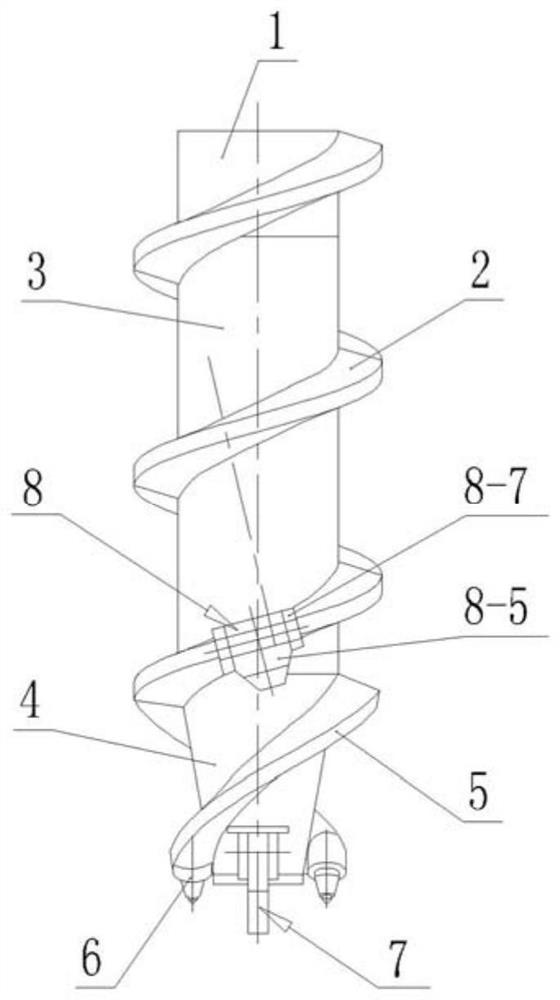

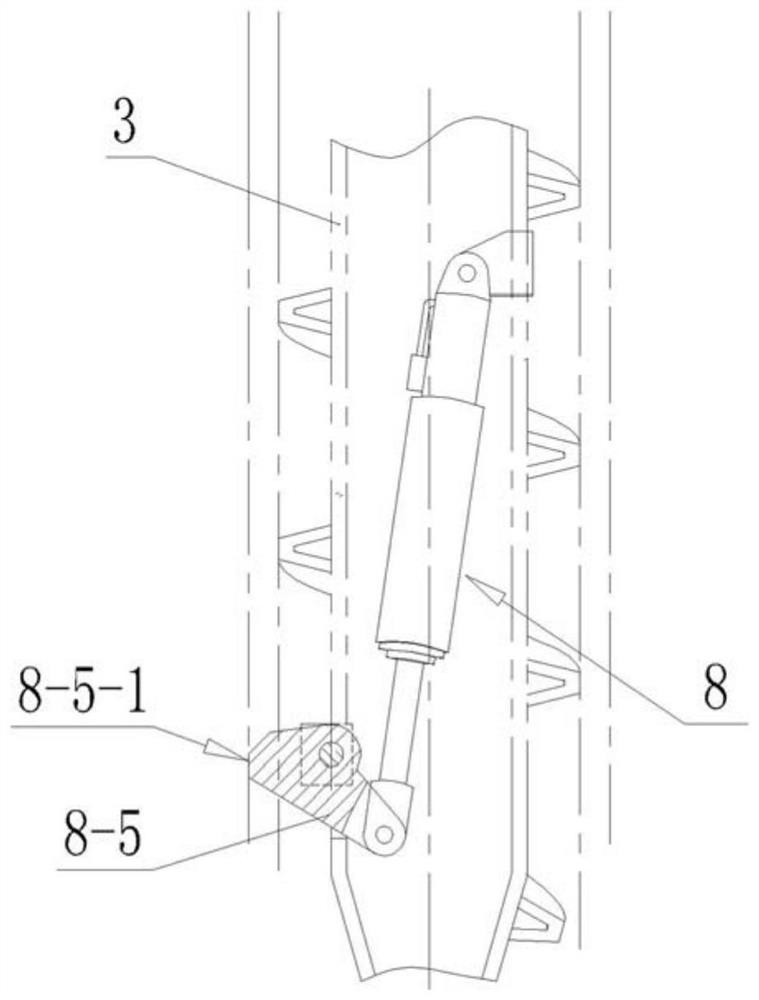

[0060] like Figure 1-Figure 12 As shown, a drill bit device for concrete pouring pile with enlarged diameter screw pile section, including joint (1), spiral blade I (2), core pipe I (3), core pipe II (4), Helical blade II (5), cutting teeth (6), drill point device (7) and rotary slider mechanism (8).

[0061] Joint (1), core pipe I (3) and core pipe II (4) are sequentially fixed coaxially to form an integrated structure, and there is a channel for concrete to pass through inside, and the joint (1) and core pipe I (3) The outer surface of the spiral blade I (2) is wound, the outer surface of the core tube II (4) is wound with the spiral blade II (5), and the upper end surface of the spiral blade II (5) is correspondingly connected with the lower end surface of the spiral blade I (2) , The lower end of the helical blade II (5) is provided with cutting teeth (6). The drill point device 7 is located at the lower end of the core pipe II4.

[0062] In one embodiment, the piling ...

Embodiment 2

[0085] (1) Structure of concrete pouring pile with enlarged diameter screw pile section

[0086] like Figure 13-Figure 18 Shown, a kind of concrete cast-in-place pile with enlarged diameter screw tooth pile section comprises concrete main body pile (10), and described concrete main body pile (10) is made of pile bottom (11), pile body part (12) and pile top ( 13) Composition.

[0087] The shape of the bottom of the pile (11) is an enlarged head structure (14) formed by extending the concrete main pile (10) to the surroundings through multiple compacted concrete.

[0088] A thread pile section (15) is provided, and the thread pile section (15) is an outwardly protruding spirally coiled thread (17) with an integral structure formed on the outer edge of the concrete main body pile (10); The section of the thread (17) is trapezoidal; the threaded pile section (15) is arranged on the pile body (12) and / or the pile top (13).

[0089] There is at least one section of enlarged-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com