Pipe joint structure

A technology for pipe joints and structures, applied in the direction of pipes/pipe joints/fittings, sealing surface connections, passing components, etc., can solve the problems of complex shapes, time-consuming, and large number of parts, and achieve simple shapes of parts and easy operation. The effect of high efficiency and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

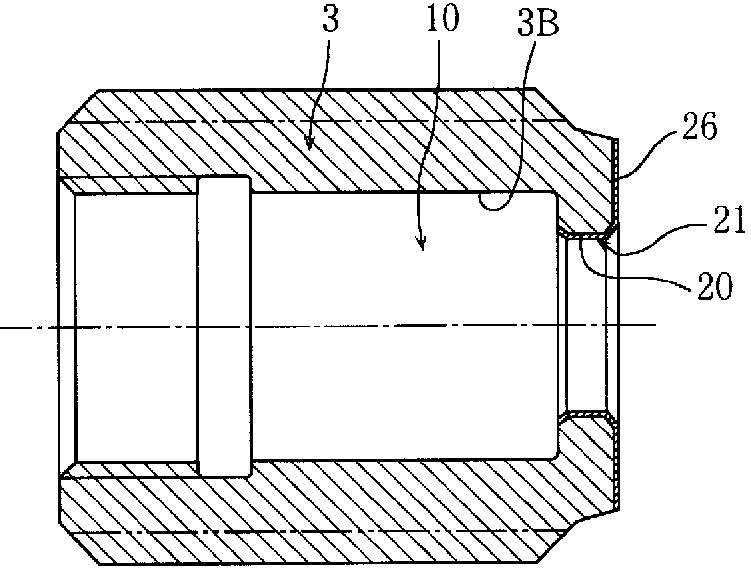

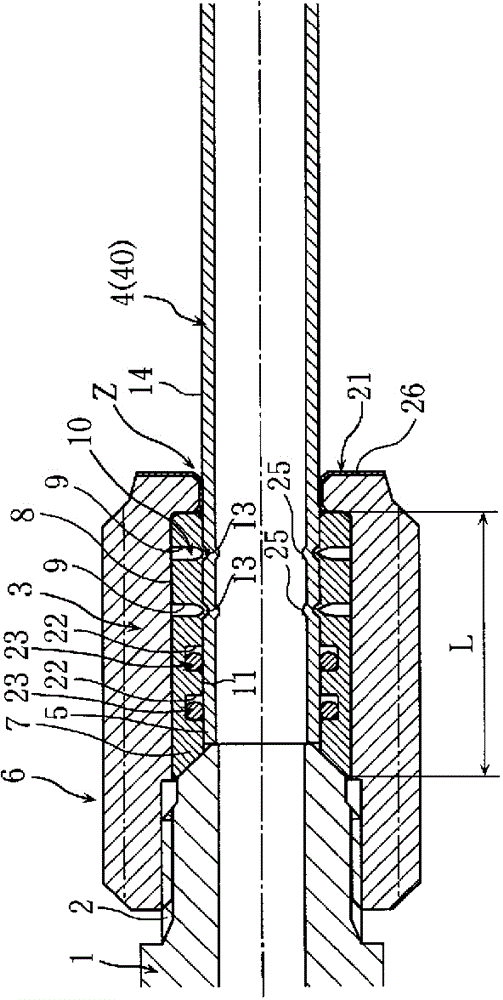

[0037] figure 1 The state before the connection of the aluminum pipe of 1st Embodiment of this invention is shown. figure 2 Shows the connection completion status. The pipe joint structure is a joint body 1 with an external thread and a cap nut 3 screwed on the external thread 2 to connect the aluminum pipe 4, and its structure is especially suitable for piping for refrigerants. The aluminum pipe 4 and the pipe joint 6 can be connected without performing flare processing on the end portion 5 of the aluminum pipe 4 . The joint main body 1 and the cap nut 3 are made of brass, for example. A refrigerant / refrigerant of an air conditioner or the like flows through the aluminum pipe 4 and the pipe joint 6 .

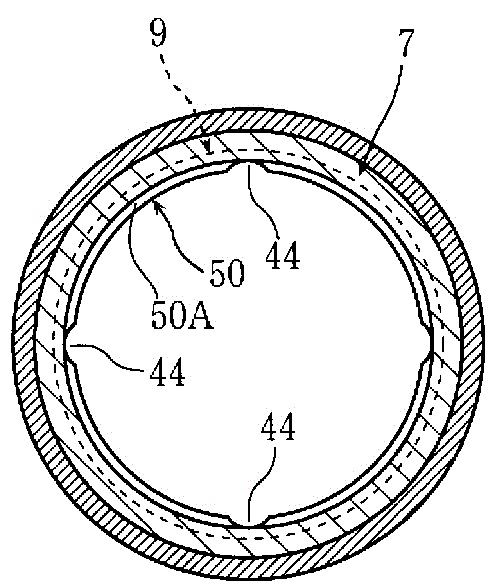

[0038] image 3 (A) shows the sleeve 7 for compression deformation made of aluminum. The sleeve 7 for compression deformation has two U-shaped concave peripheral grooves 9 on the outer peripheral surface 8 . Such as figure 1 , figure 2 As shown, the compression defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com