Full-thread pile pouring machine extruding soil body and pile-forming construction method thereof

A full-threaded, cast-in-place pile technology, applied in sheet pile walls, earth-moving drilling, rotary drilling rigs, etc., can solve the problems of small bearing capacity, complicated construction and operation, poor practicability, etc., and achieve high bearing capacity, increase contact area, The effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

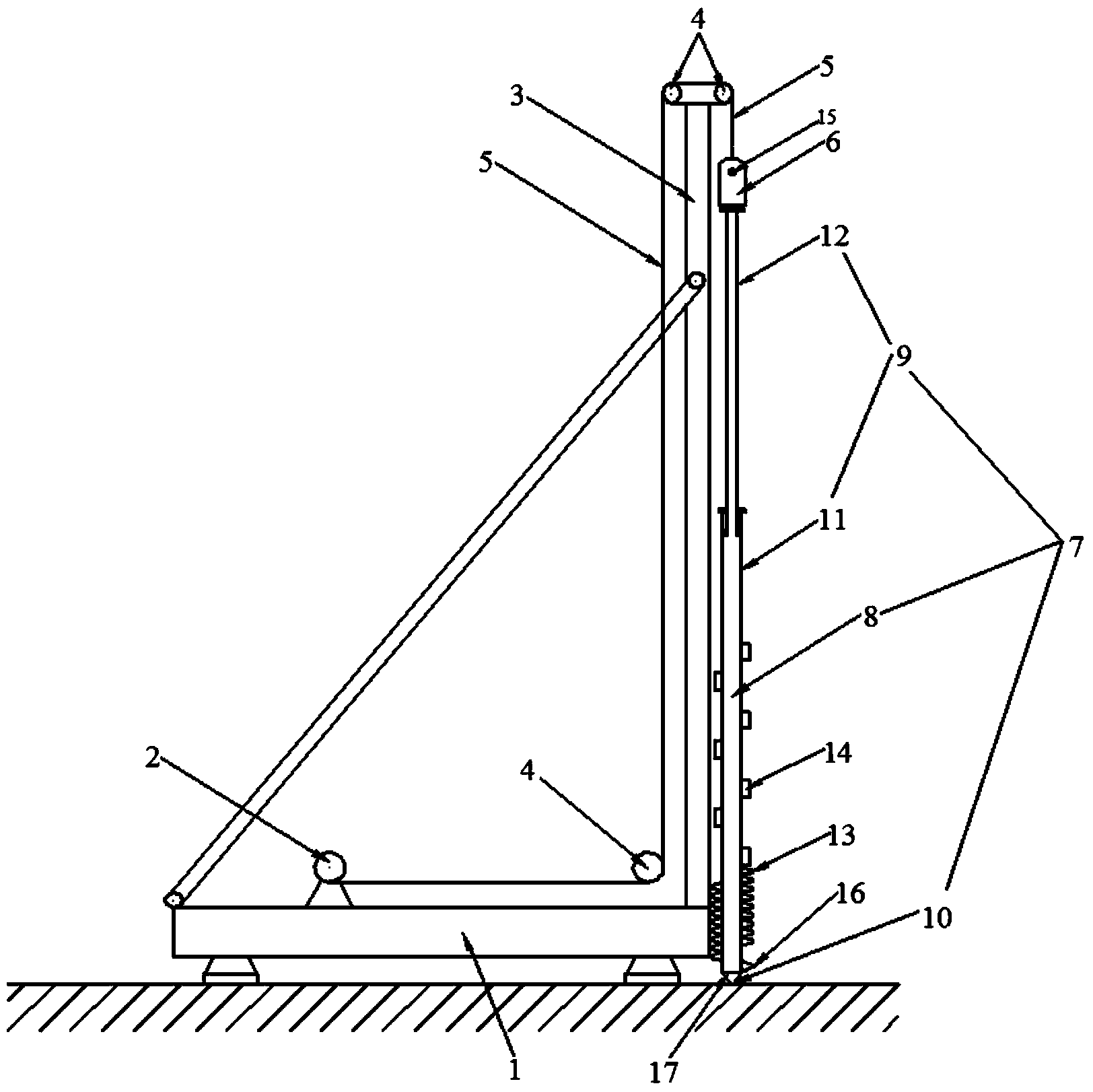

[0029] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

[0030] Please refer to Fig. 1, the present invention provides an extruded soil fully threaded cast-in-situ pile driver, including a base 1, a hoist 2, a vertical frame 3, a pulley 4, a traction rope 5, a motor device 6, and a drill rod 7 , wherein, the erecting frame and hoist are arranged on the base, the motor device is arranged on the guide rail of the erecting frame (not marked in the guide rail figure), and the pulleys are arranged on the top and bottom ends of the erecting frame, One end of the traction rope is fixedly connected to the winch, the middle part is hung on the pulley, and the other end is fixedly connected to the top end of the motor device. The drill pipe includes a vertical drill pipe shaft with a hollow concrete delivery chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com