Assembled steel structure

A steel structure and assembly technology, applied in the direction of building structure, construction, etc., can solve problems such as difficulty in finding a suitable layout position for support, difficult lateral force system of frame column network, and affecting the use function of indoor buildings, etc., to solve the problem of convex column Solve the sun angle problem, avoid buckling and collapse of steel columns, and improve the effect of bearing capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to improve the lateral resistance of the assembled steel structure, improve the bearing capacity and stability of the building, and adapt to the functional requirements of the building, the embodiment of the present invention provides an assembled steel structure. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

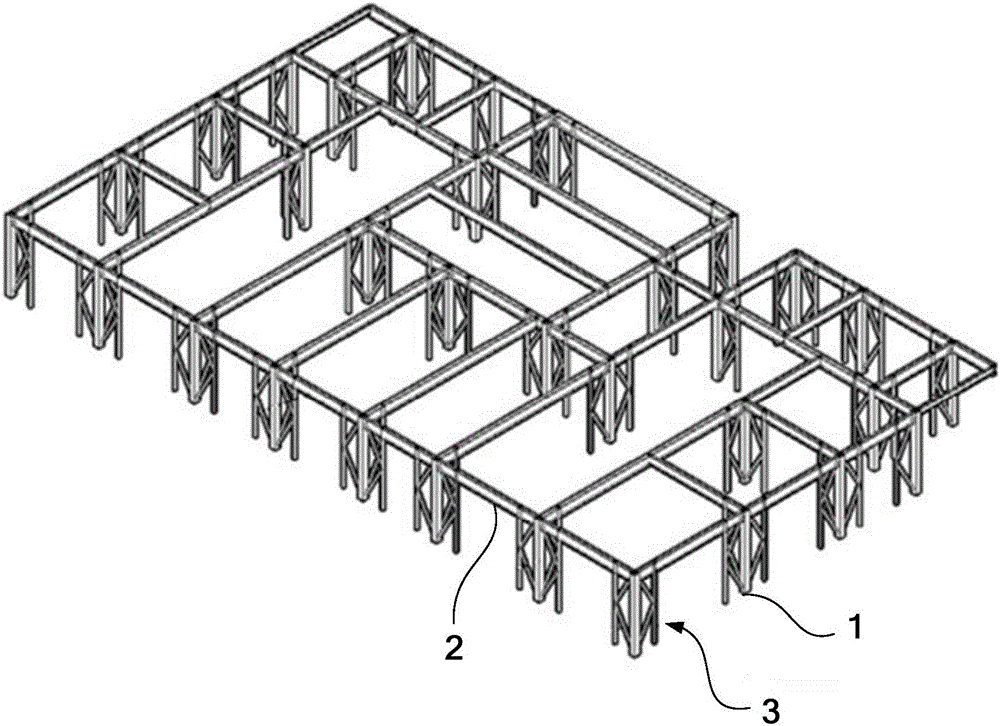

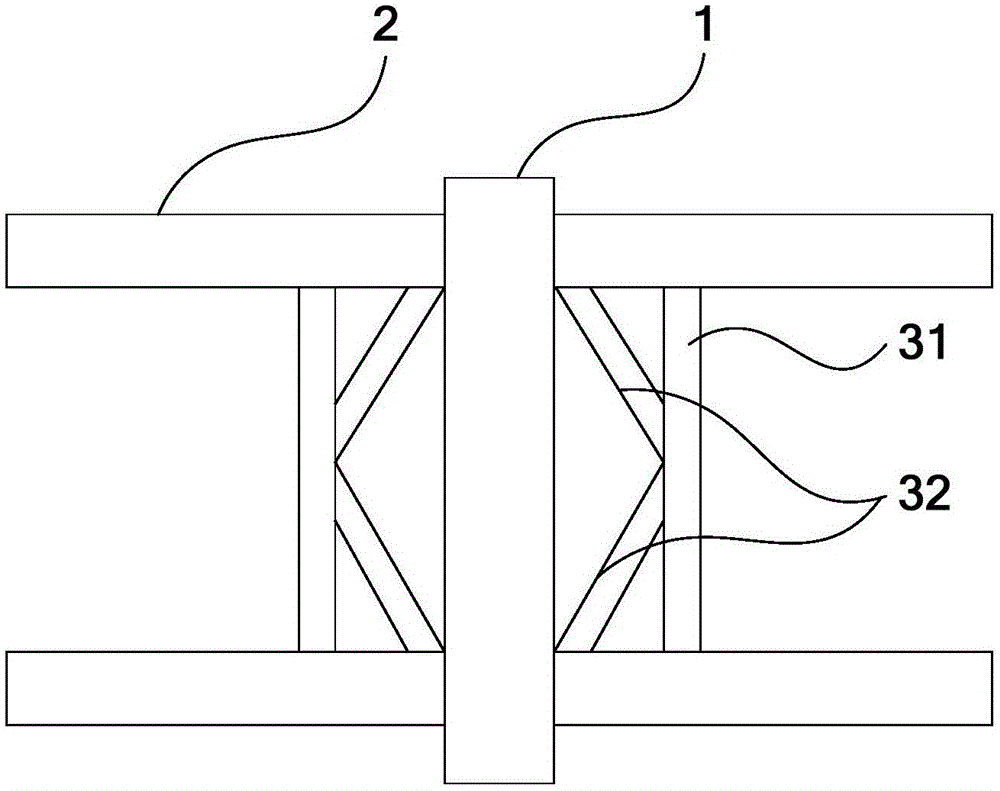

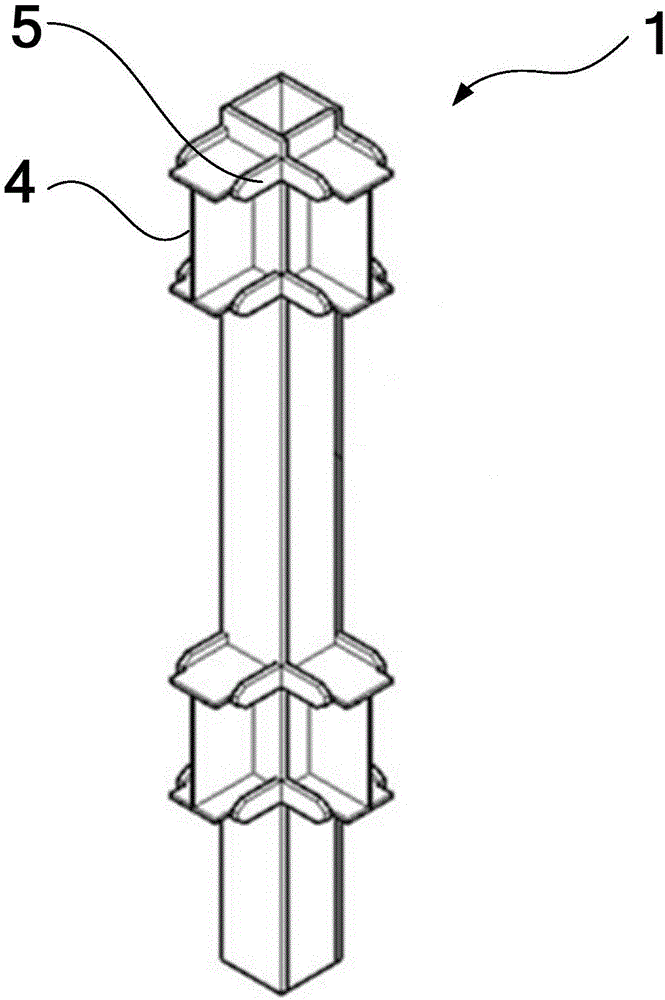

[0038] refer to figure 1 and figure 2 , the fabricated steel structure provided by an embodiment of the present invention includes a plurality of vertical columns 1 erected in parallel, multiple beams 2 arranged horizontally and connecting the multiple columns 1 , and corresponding to each column 1 and each beam 2 The K-shaped bracing frame 3 provided at the junction of each K-shaped bracing frame 3 includes a vertical strut 31 and two diagonal struts 32, and each vertical strut 31 is vertically arranged and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com