Patents

Literature

41results about How to "Uniform force point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

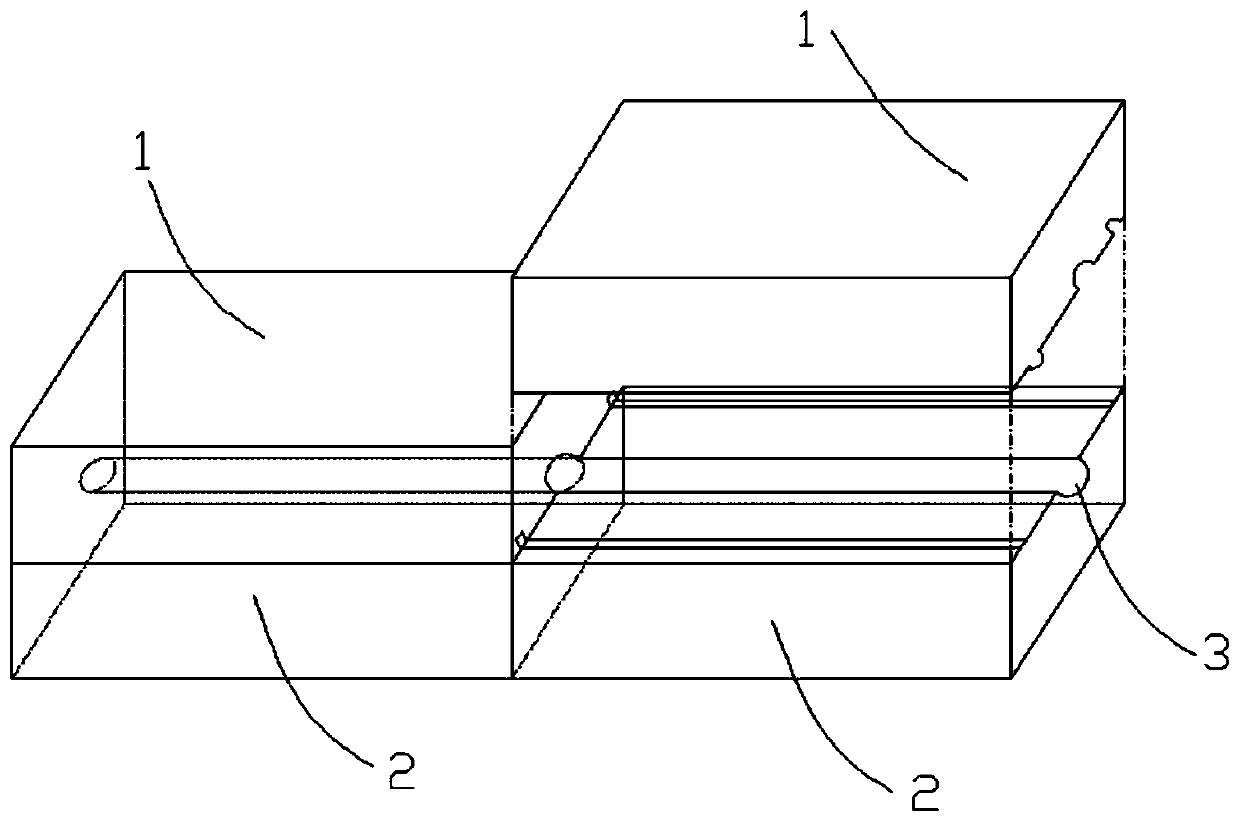

Slot

InactiveCN101997287AGood strengthNo electromagnetic interferenceCable installations on groundElectricityStress point

The invention relates to a slot which comprises a shell used for accommodating a cable, a baffle plate arranged at the middle of the shell, and an openable cover plate matched with the shell, wherein two sides of the shell are provided with first supporting parts used for supporting the cover plate, the upper end of the baffle plate is provided with a second supporting part used for supporting the middle of the cover plate; and the shell is formed by once extrusion of an aluminum alloy. Because the baffle plate is arranged at the middle of the shell, strong electricity and weak electricity are physically isolated without electromagnetic interference; meanwhile, the slot has the advantages of reasonable structure, high process precision, uniform stress point, strong stress, pressure bearing of 500Kg, long service life; due to the arrangement of the openable cover plate, the slot is convenient maintenance; and a decorative material can be attached on the cover plate, thus the slot is attractive and uniform.

Owner:GUANGZHOU HOLDSTORM SCI & TECH

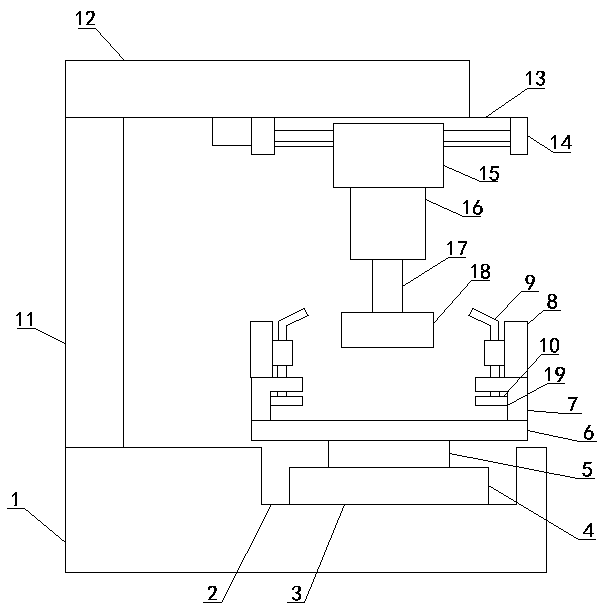

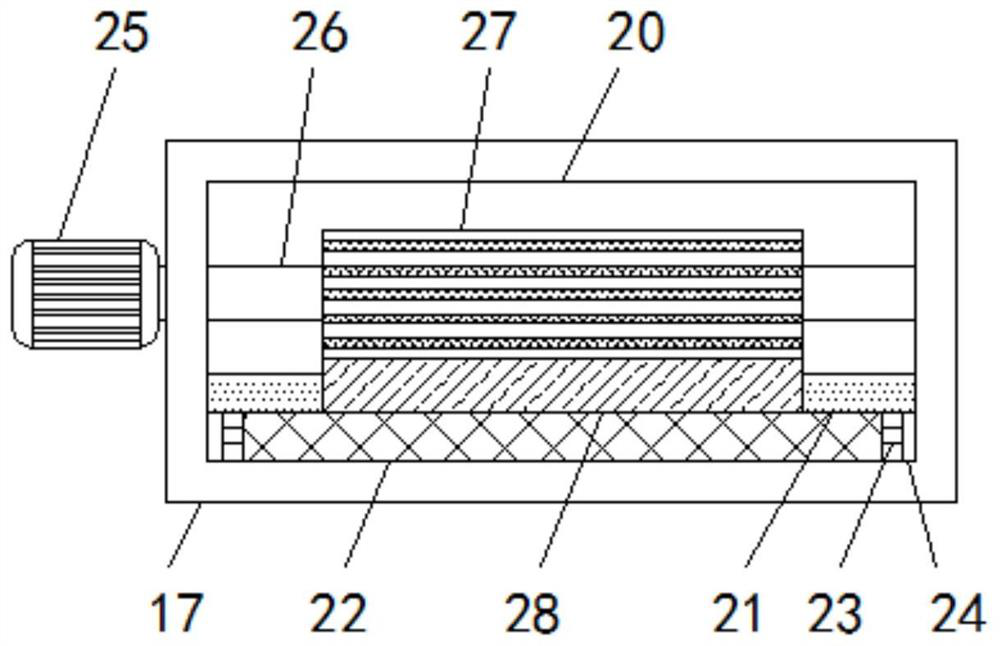

Grinding device applied to glass surface machining

InactiveCN105345645AImprove grinding effectExtended service lifeLapping machinesLapping toolsGlass chipEngineering

The invention discloses a grinding device applied to glass surface machining. The grinding device comprises a working platform, a grinding frame, grinding mechanisms and a grinding fluid mechanism. The grinding frame comprises a first grinding frame body and a second grinding frame body. The grinding mechanisms are arranged above the first grinding frame body and the second grinding frame body. The grinding mechanisms comprise grinding discs, telescopic rods and fixed rods. Pressurizing blocks are arranged above the grinding discs. Grinding skins are arranged at the bottoms of the grinding discs. Grinding grooves are formed in the grinding skins, and scale marks are arranged on the telescopic rods. The grinding device is simple in structure and high in practicality; due to the design of the grinding frame, the situation that glass chips generated in the glass grinding process are splashed out to hurt operators is effectively avoided; due to the design of the first grinding frame body and the second grinding frame body, working efficiency is improved; and due to the design of the pressurizing blocks, the number of the pressurizing blocks can be increased or decreased according to the glass machining sizes and machining requirements, so that grinding pressure is more suitable for current glass grinding, and working quality is further improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

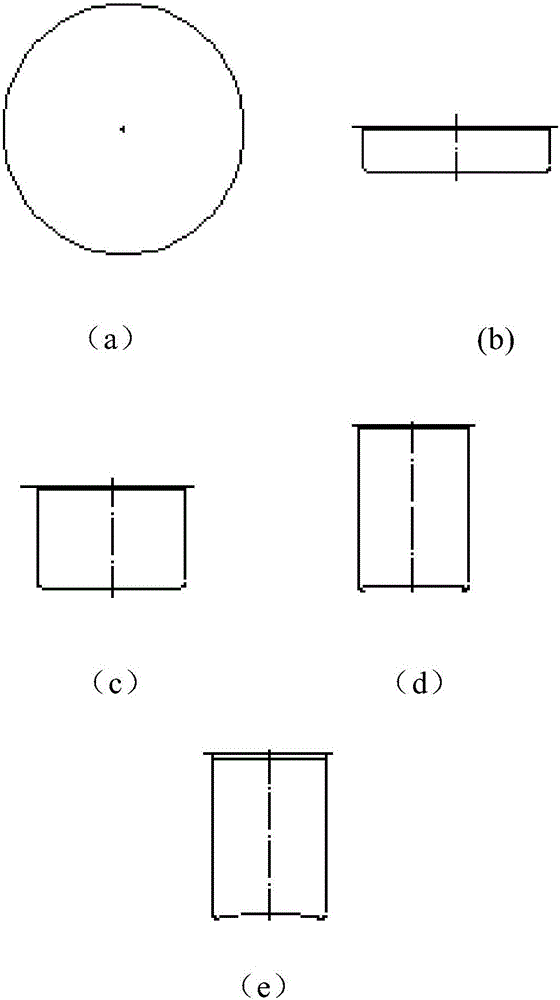

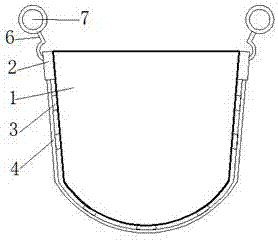

Seamless tank and manufacturing method thereof

InactiveCN105834322ASmooth appearanceAvoid Corrosion ConditionsHollow articlesPunchingBiochemical engineering

The invention provides a seamless tank and a manufacturing method thereof. The manufacturing method includes the following steps that a circular flat plate raw material is obtained by blanking a film-covered material; punching is conducted on the circular flat plate raw material, so that a first U-shaped semi-finished product is obtained, and the external diameter of the first U-shaped semi-finished product is made to be at least 30% smaller than the diameter of the circular flat plate raw material; primary drawing is conducted on the first U-shaped semi-finished product, so that a second U-shaped semi-finished product is obtained, and the external diameter of the second U-shaped semi-finished product is made to be at least 35% smaller than the external diameter of the first U-shaped semi-finished product; secondary drawing is conducted on the second U-shaped semi-finished product till the second U-shaped semi-finished product reaches the tank body dimension, and then a third U-shaped semi-finished product is obtained; the top of the third U-shaped semi-finished product is trimmed, so that a tank body is obtained; and the tank body and a tank cover are connected into a whole to obtain the seamless tank. According to the seamless tank and the manufacturing method thereof, the pressure resistance strength of the tank body can be improved remarkably, and the tank body is not prone to deformation and good in corrosion resistance.

Owner:ORG TECH CO LTD

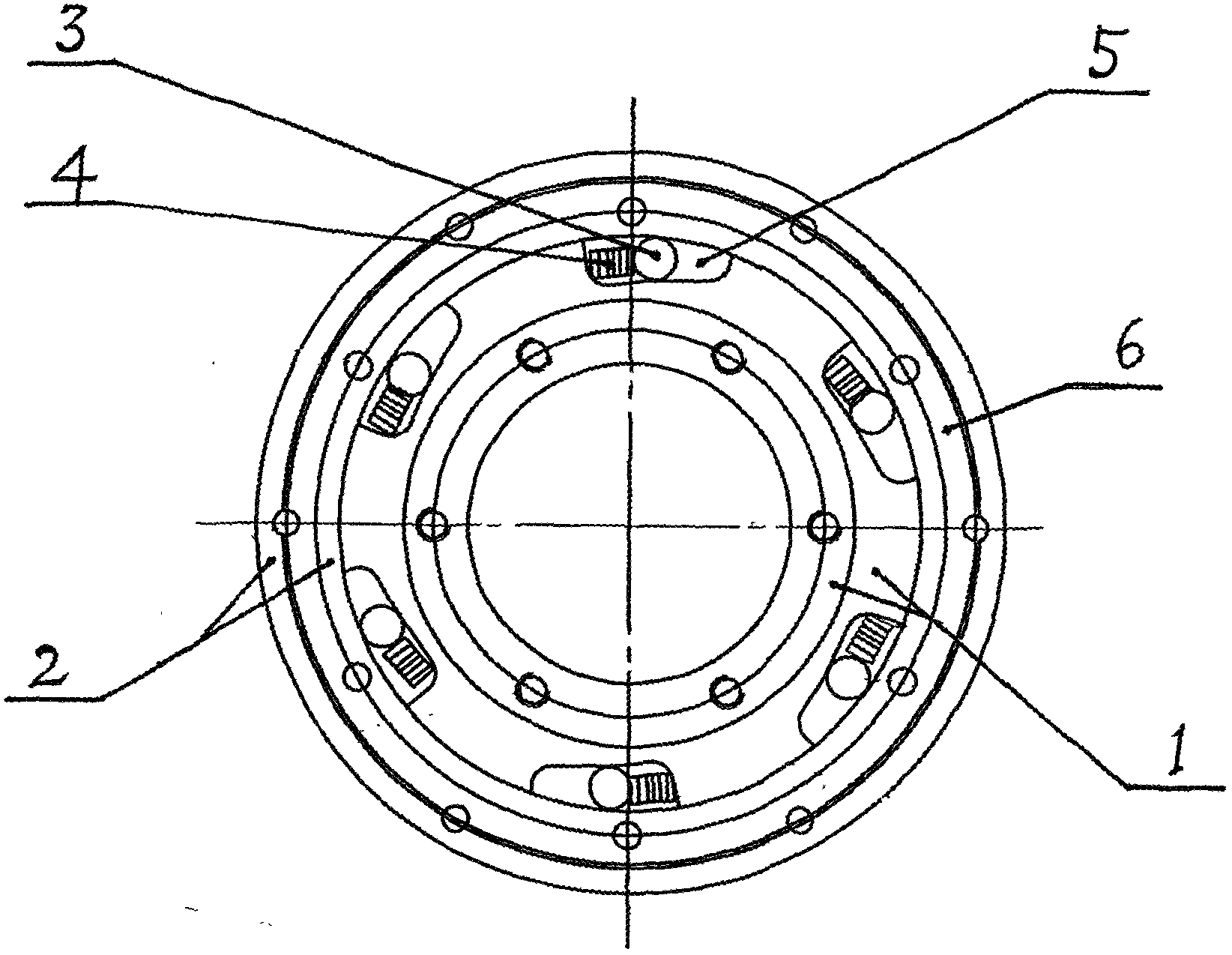

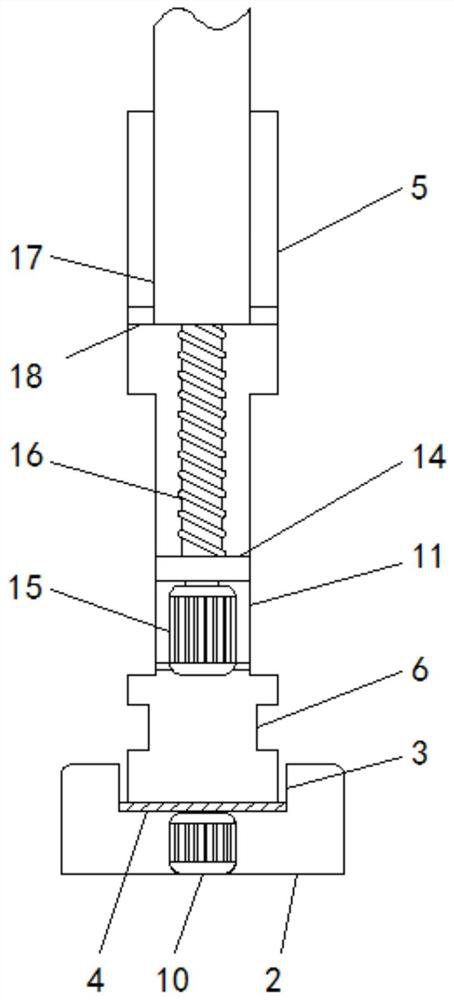

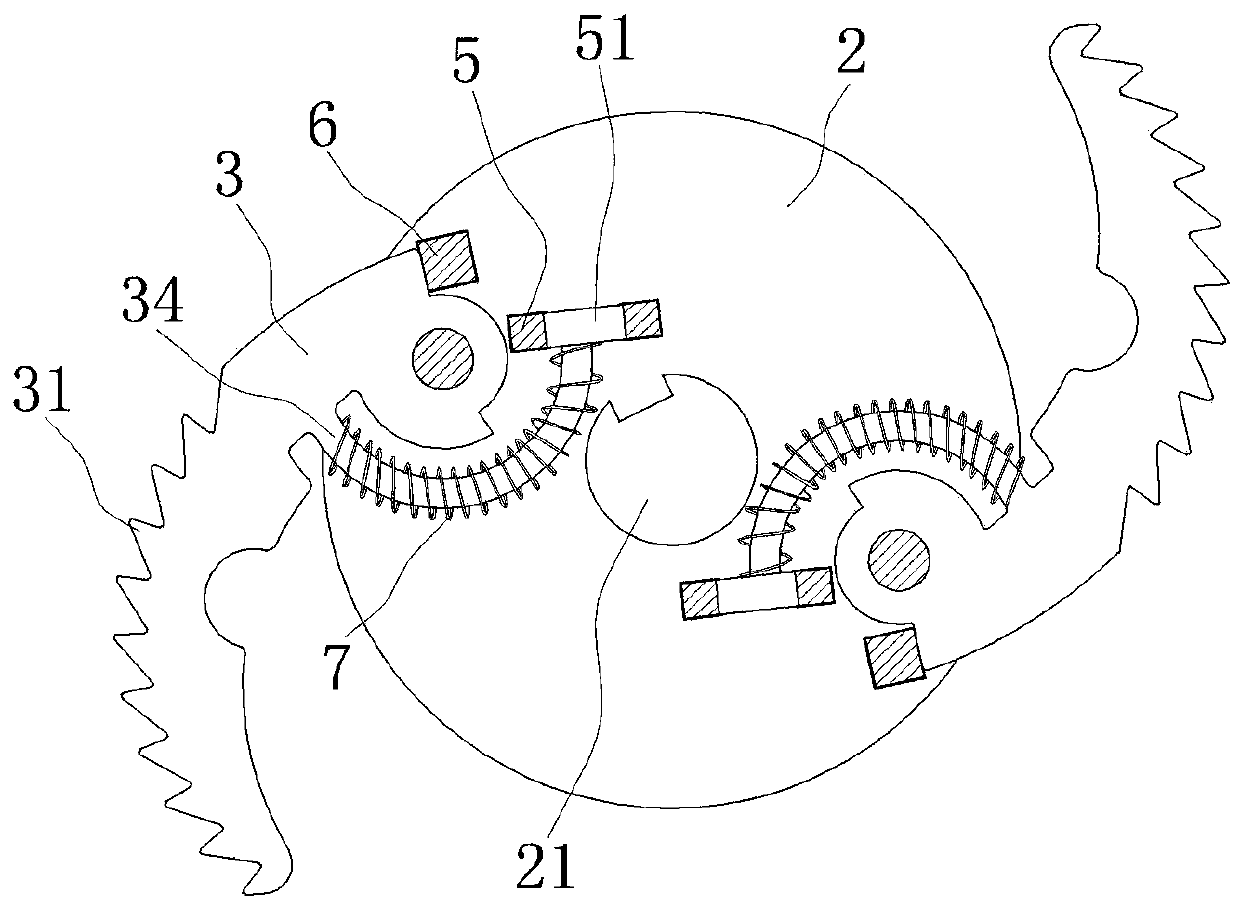

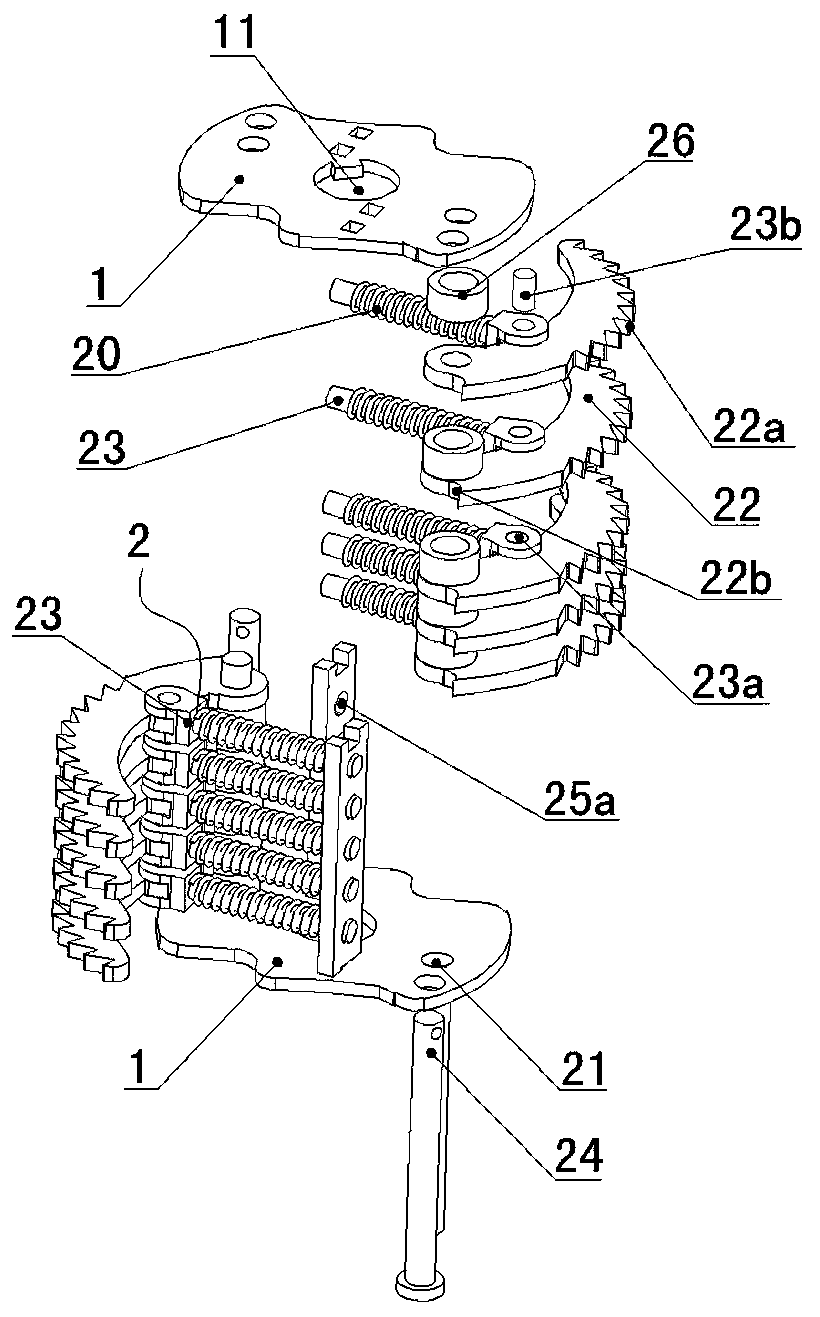

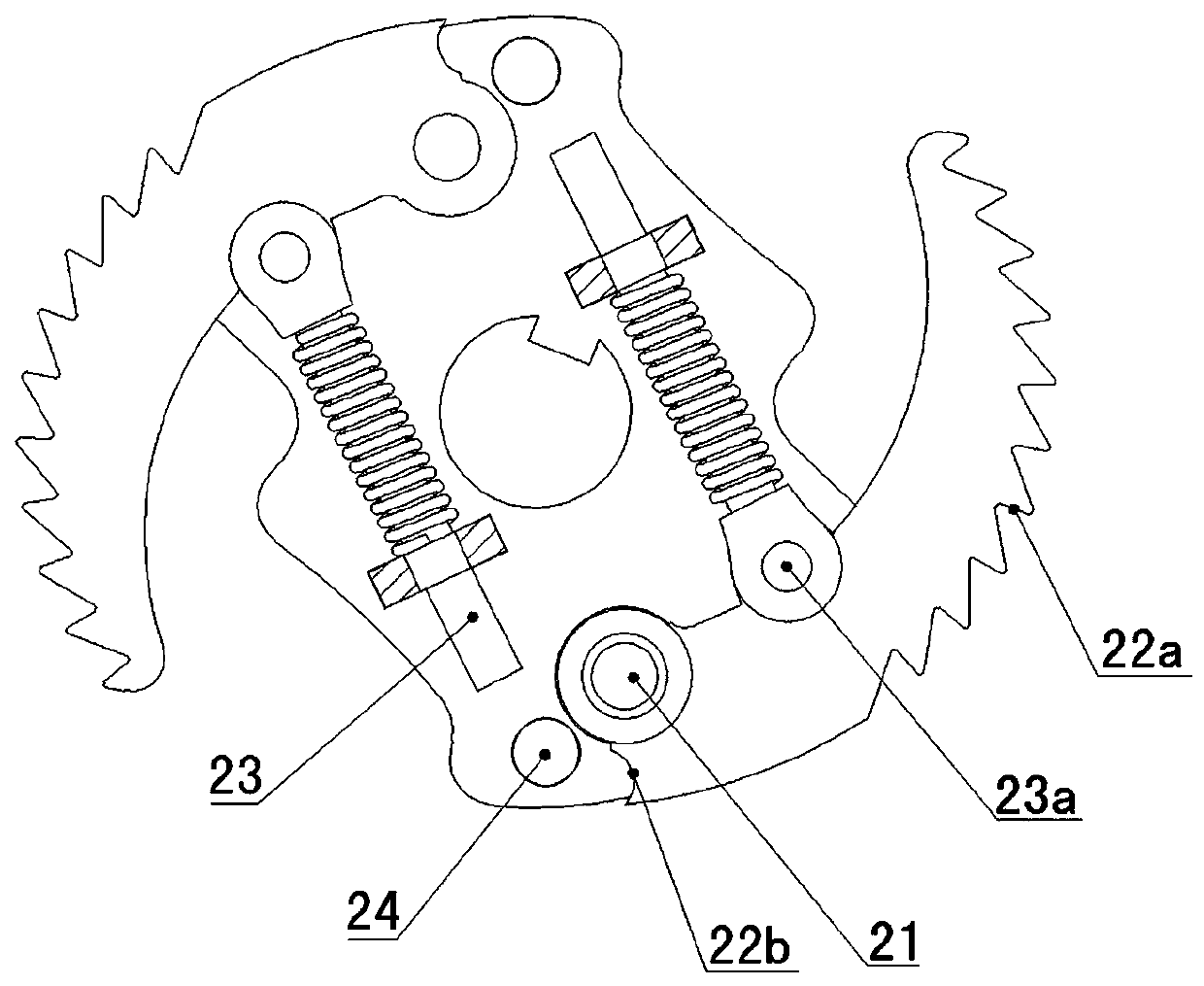

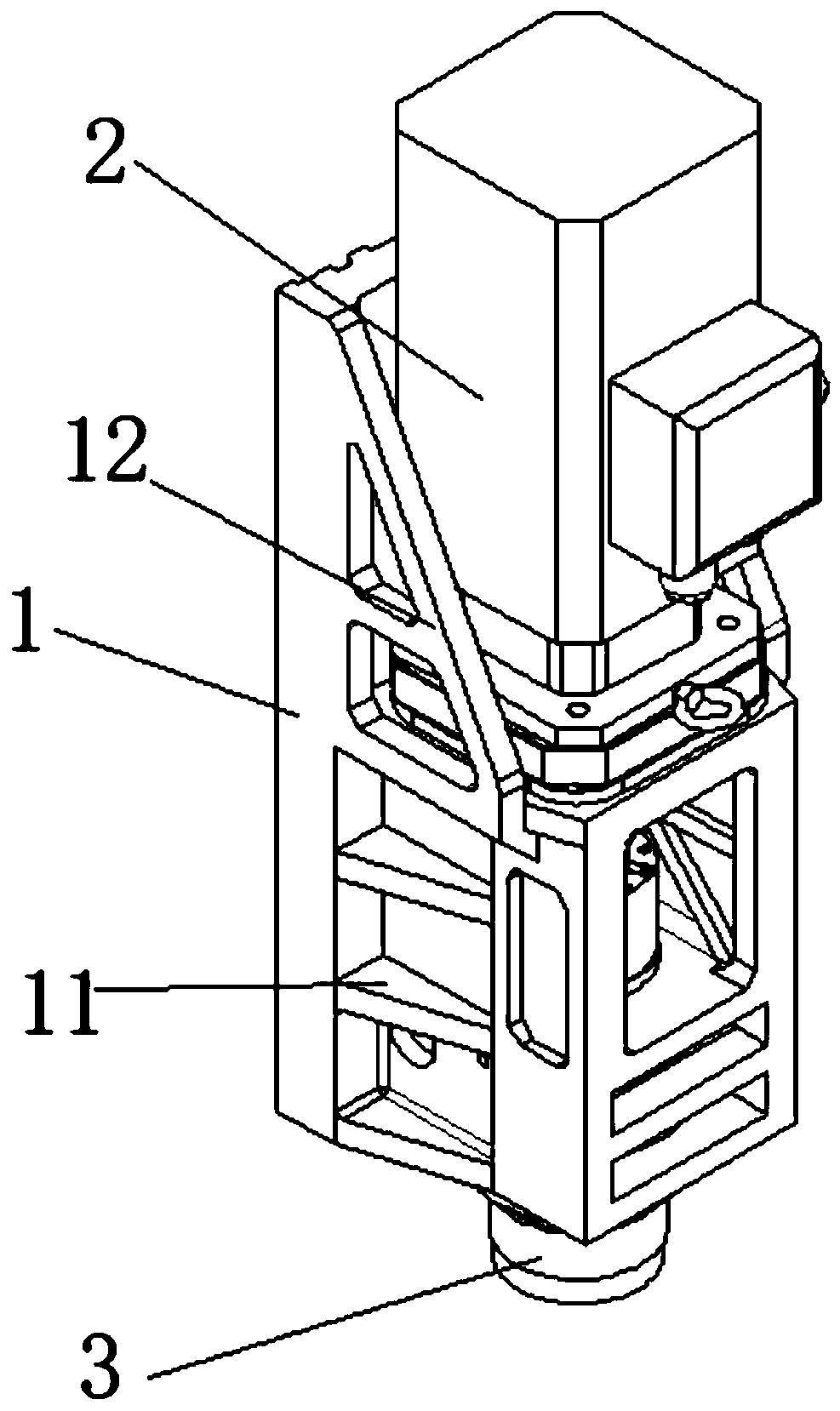

High-reliability clutch mechanism

The invention relates to a high-reliability clutch mechanism which comprises an inner shaft sleeve 1, an outer sleeve ring 2 and a driving component, wherein the outer edge of the inner shaft sleeve 1 is at least provided with a wedge-shaped groove; the driving component is arranged in the wedge-shaped groove, and the driving part, the outer sleeve ring 2 and the wedge-shaped groove form a one-way close fit structure capable of realizing forward-rotation clamping. The high-reliability clutch mechanism can be used for solving the problems of high fault occurrence possibility, poor reliability and high abrasion possibility of an existing clutch mechanism, has the advantages of high operation reliability, high stability, low noise, simple structure, easiness for manufacturing, high durability and the like, and is mainly used for manufacturing clutch devices of various vehicles and power devices.

Owner:马骥 +1

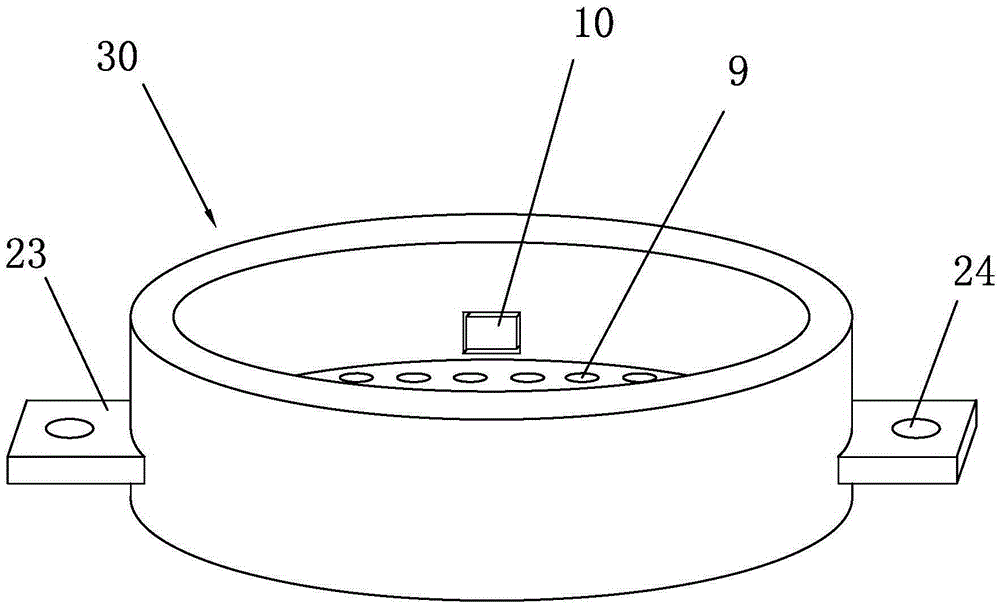

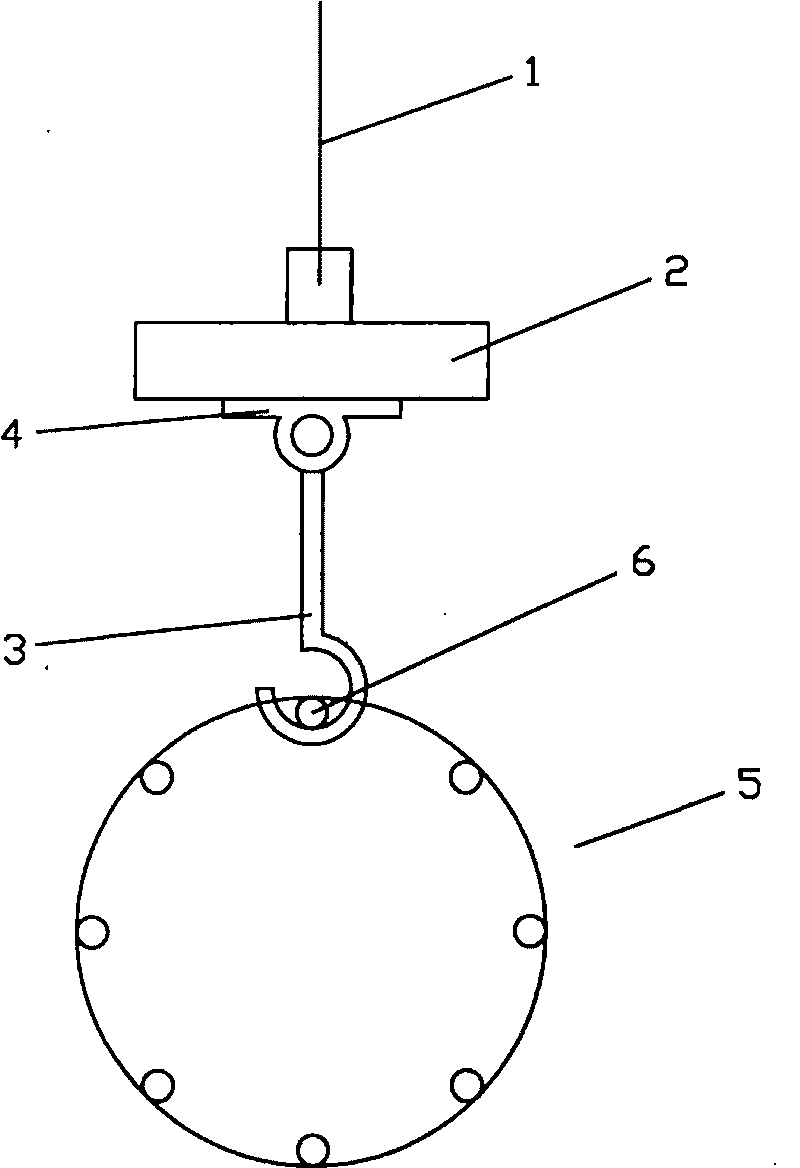

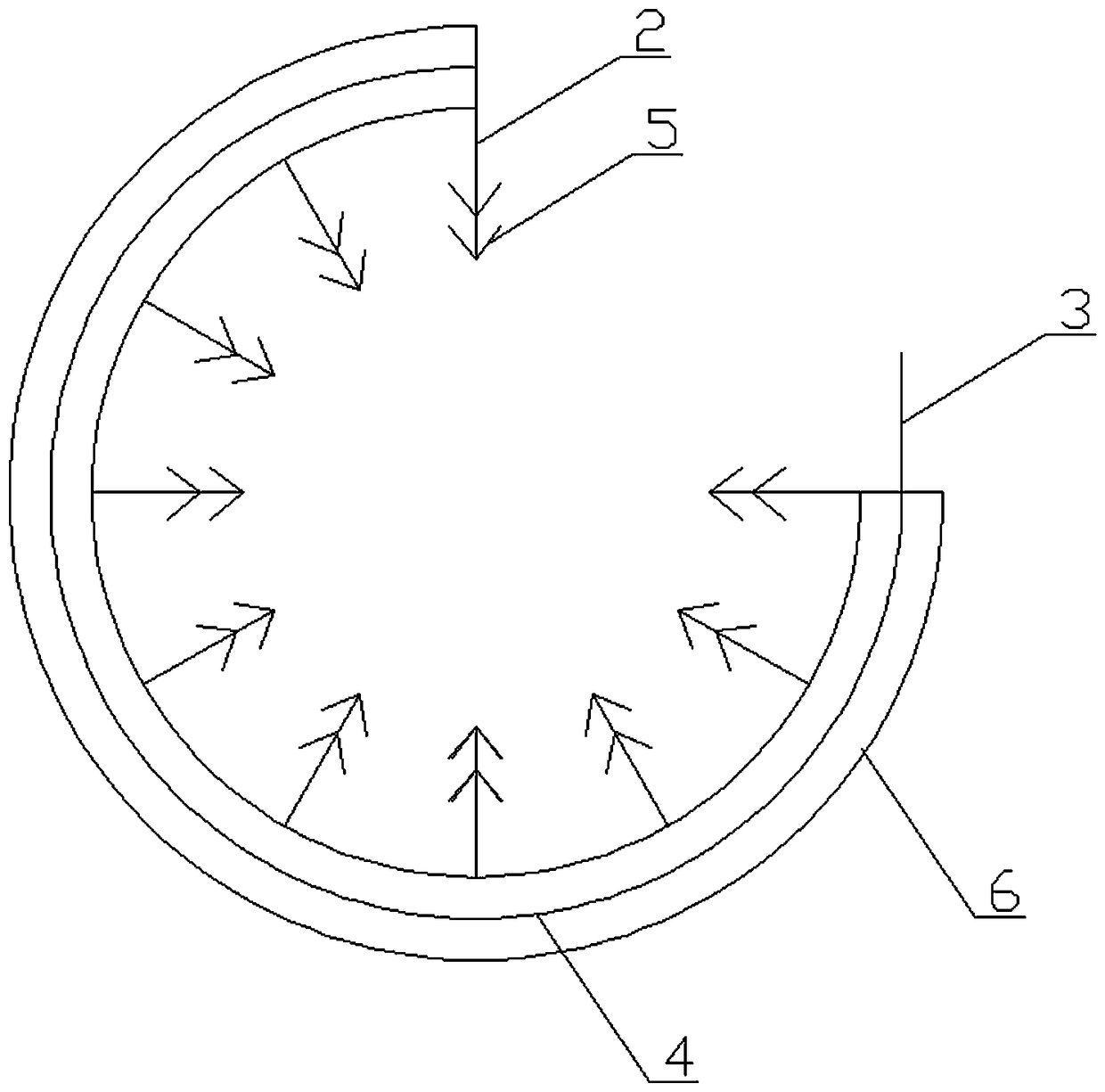

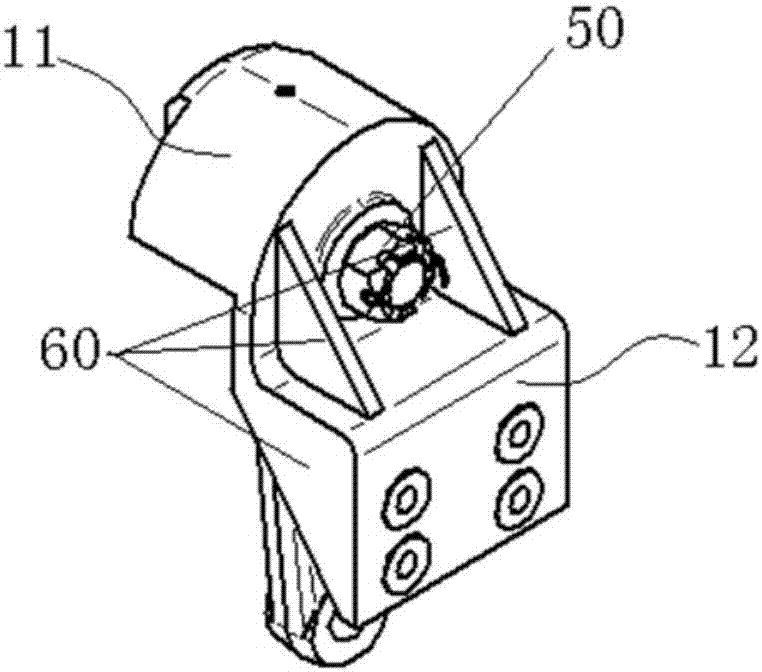

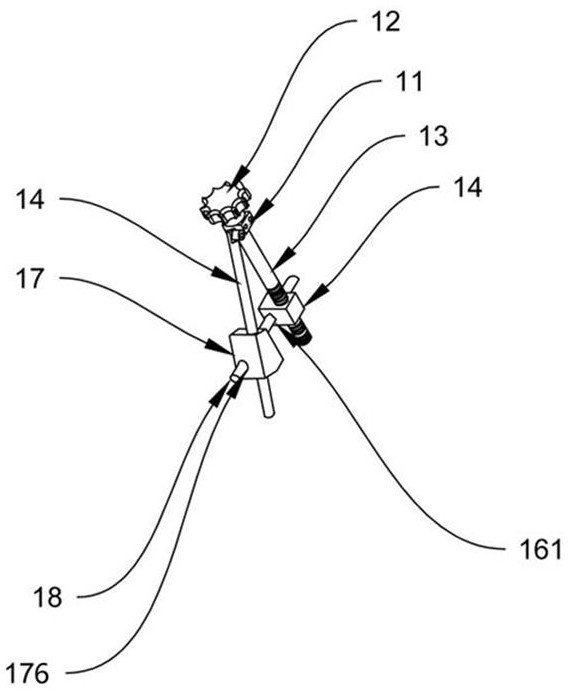

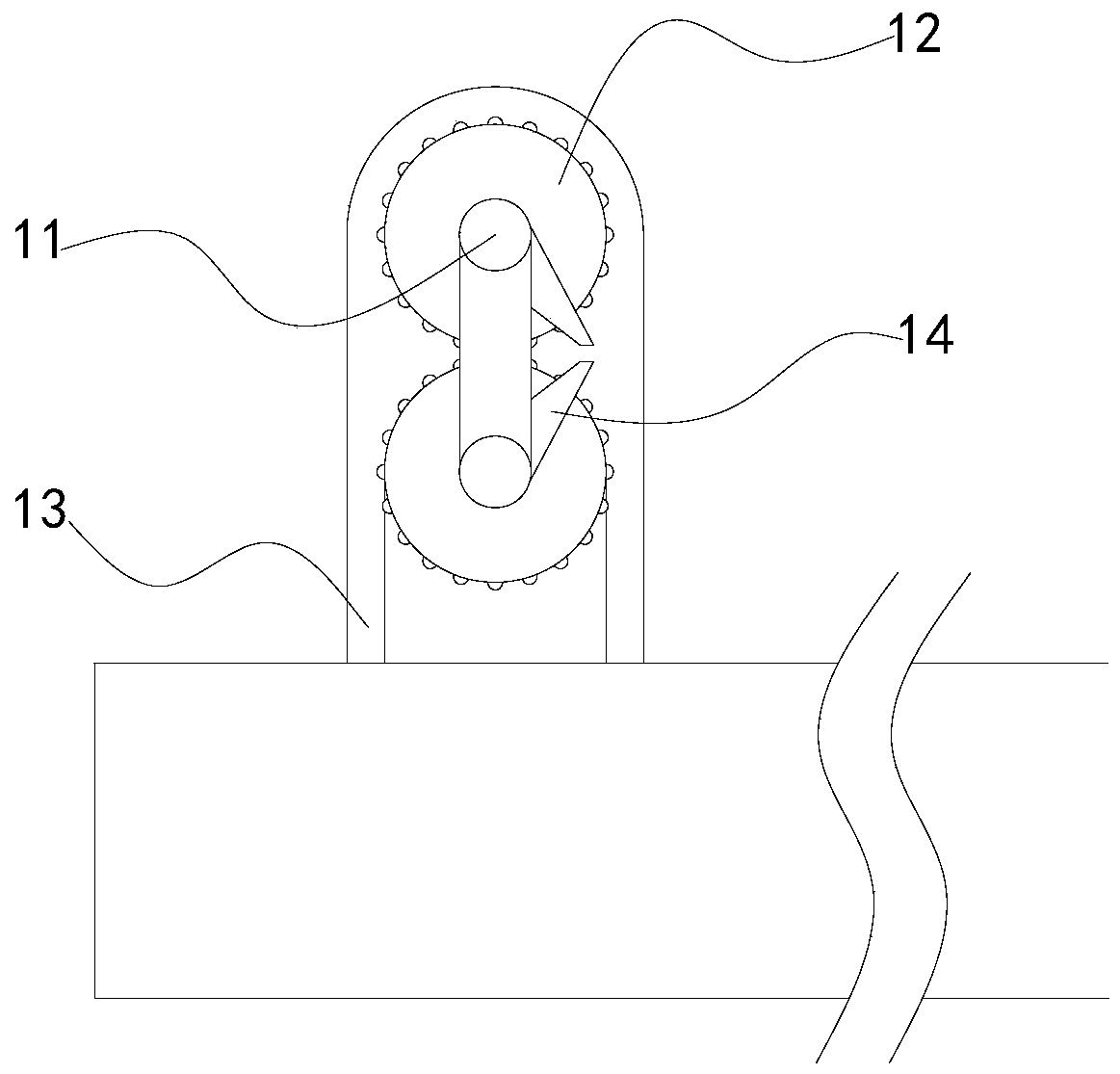

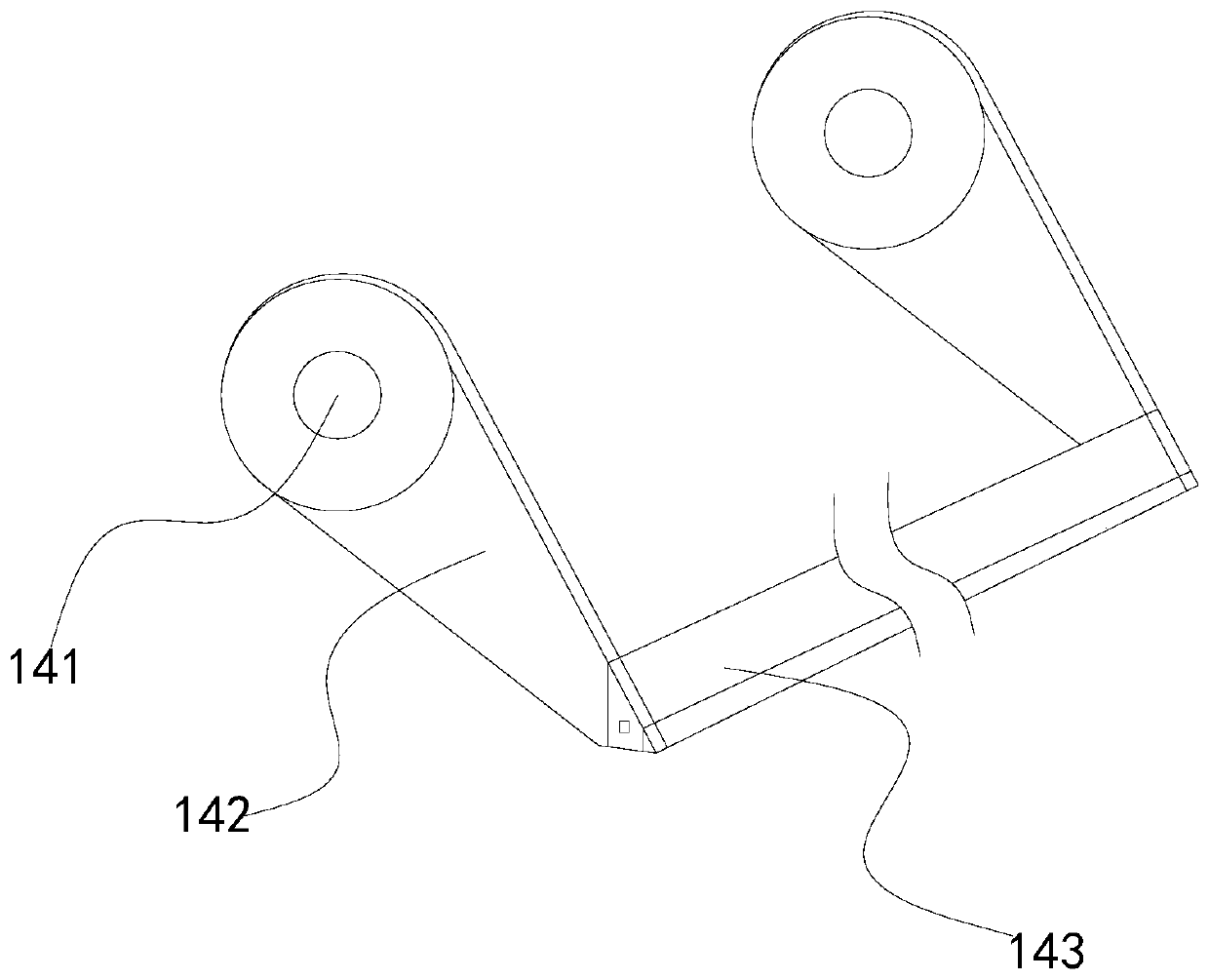

Gripping apparatus of tubular pile steel cage

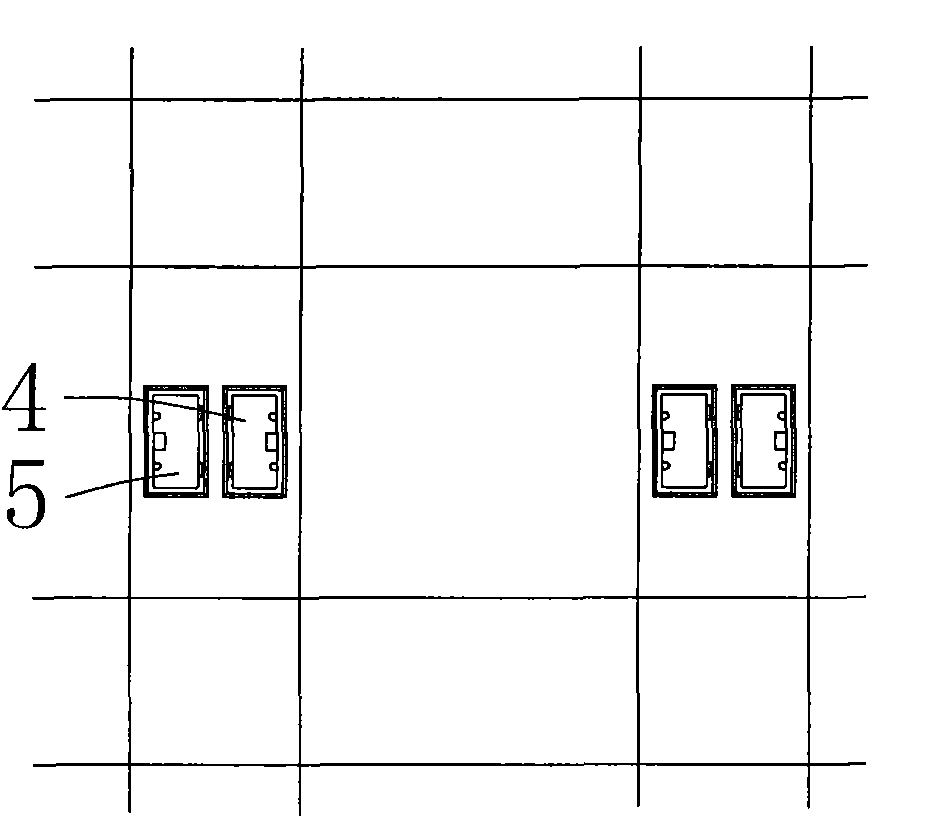

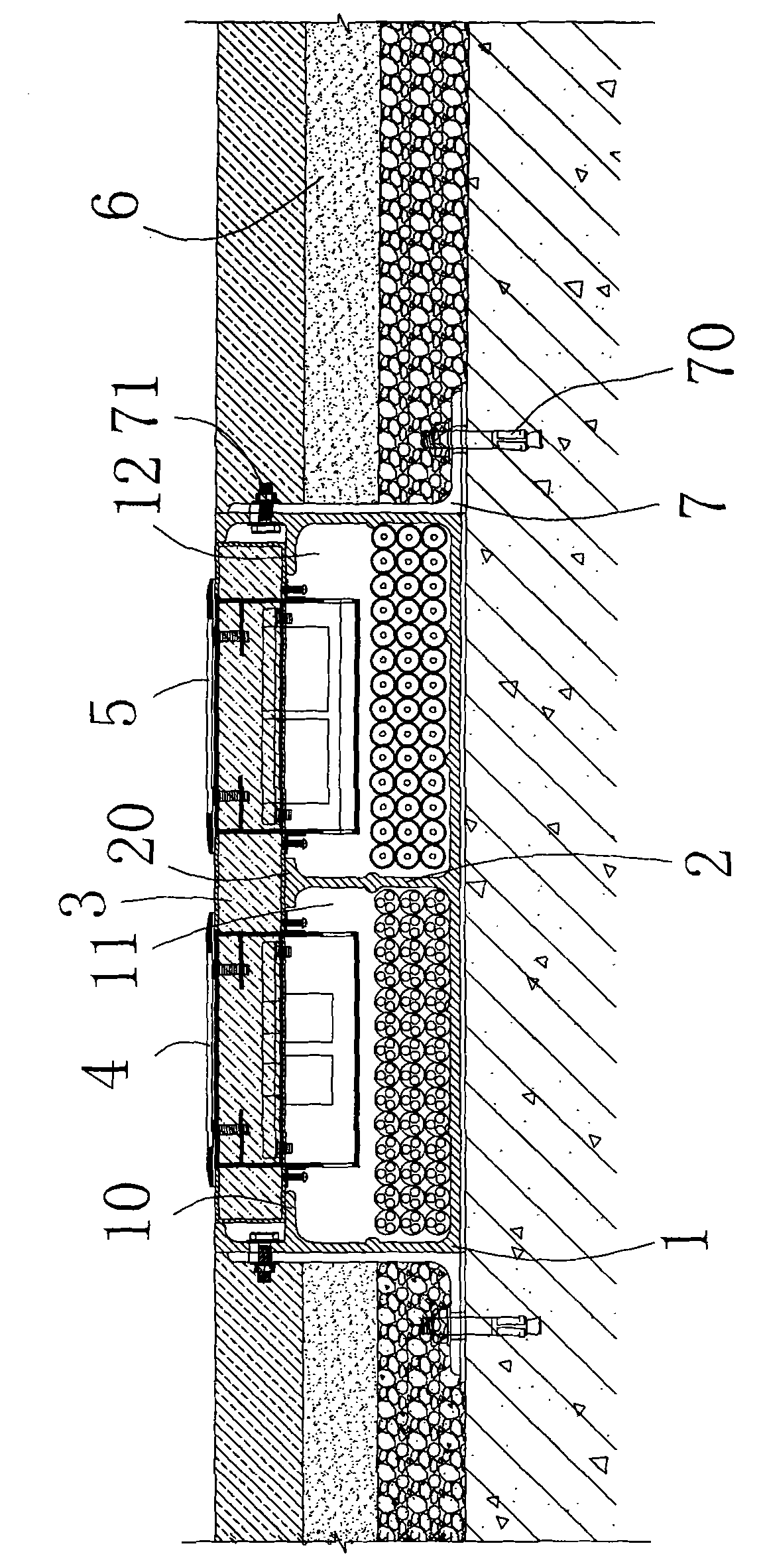

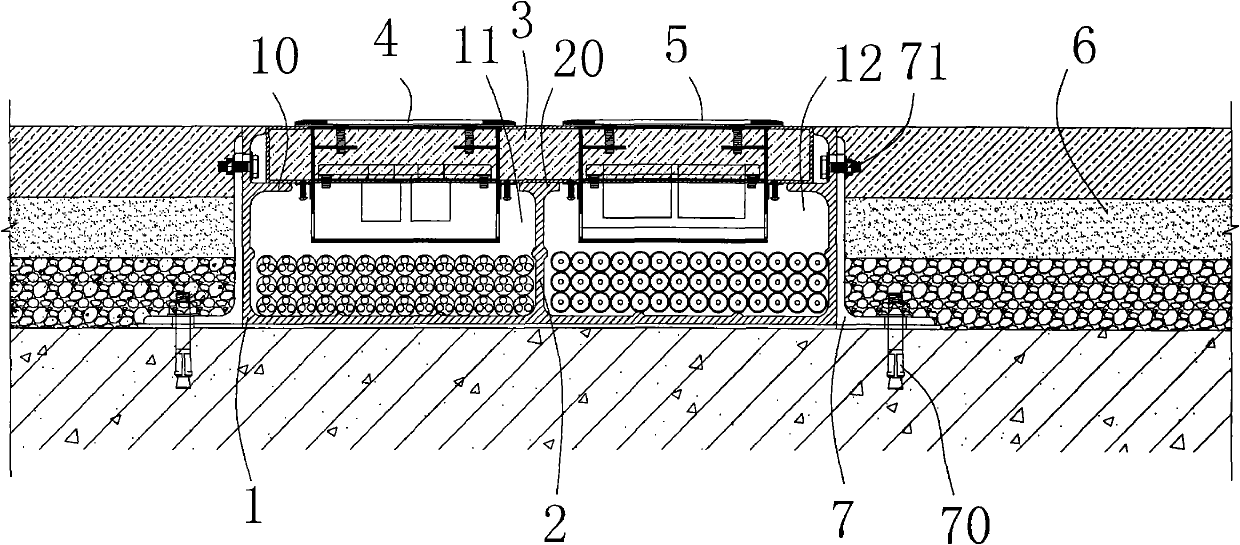

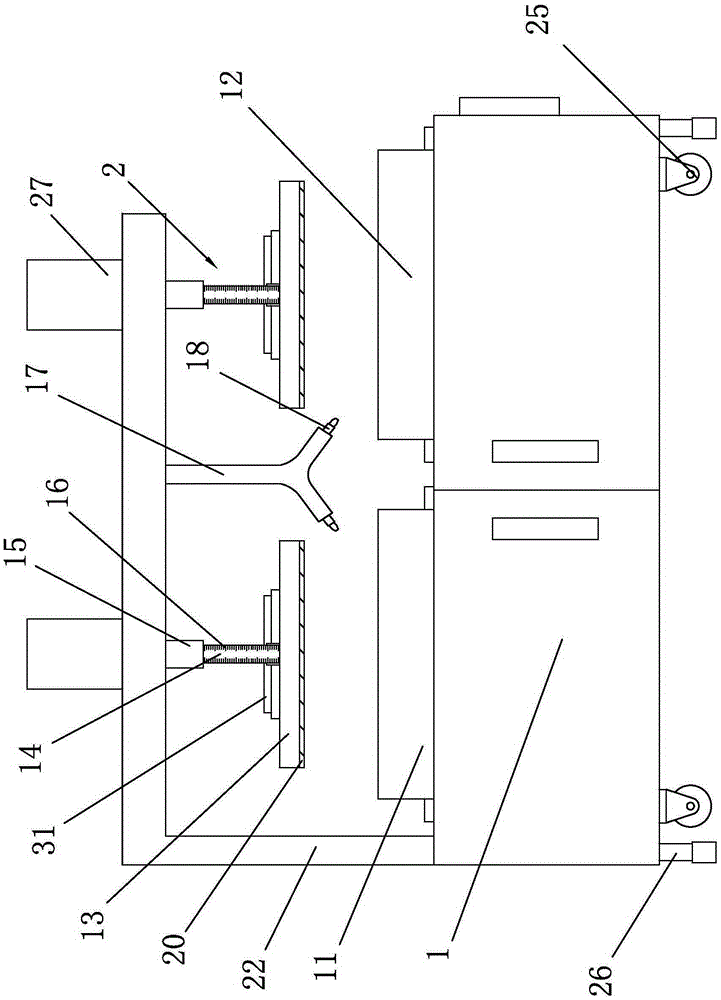

InactiveCN101717036AUniform force pointNot easily deformedLoad-engaging elementsWheel driveEngineering

The invention discloses a gripping apparatus for a tubular pile steel cage, which comprises a bridge crane rope, a bracket connected with the rope and hooks arranged below the bracket, wherein at least two hooks are arranged below the bracket, and a rotating mechanism for driving the hook to rotate is arranged between the hook and the bracket. The hooks are arranged at an equal interval; and the rotating mechanism adopts the driving mode of belt drive, chain drive, frictional wheel drive, hydraulic drive or pneumatic drive. The gripping apparatus ensures that the tubular pile steel cage is difficult to deform during the transportation, avoids damages to the steel cage, can automatically hook the steel cage, is safe in operation, improves efficiency and saves labor cost.

Owner:GUANGDONG SANHE PILE CO LTD

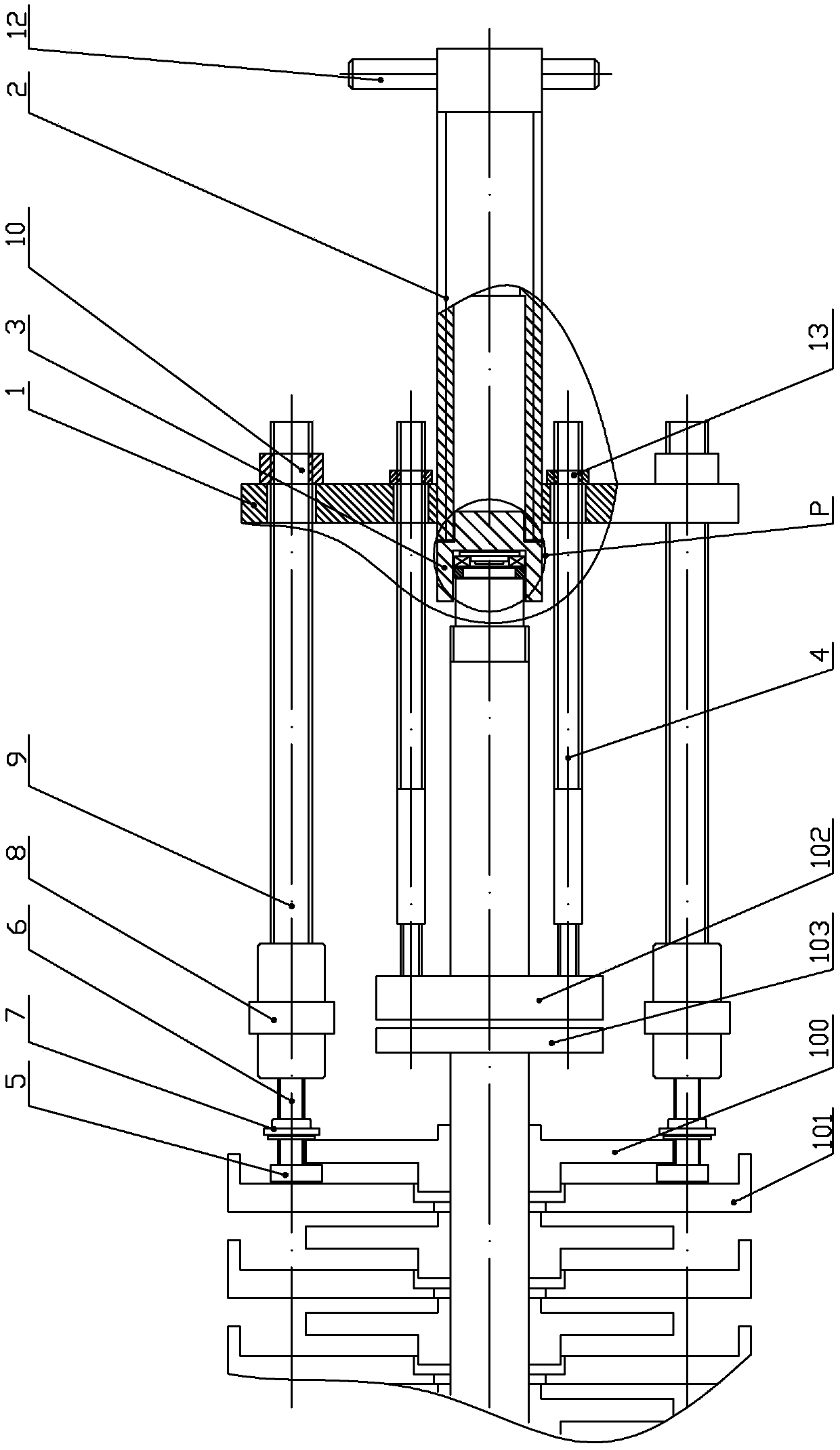

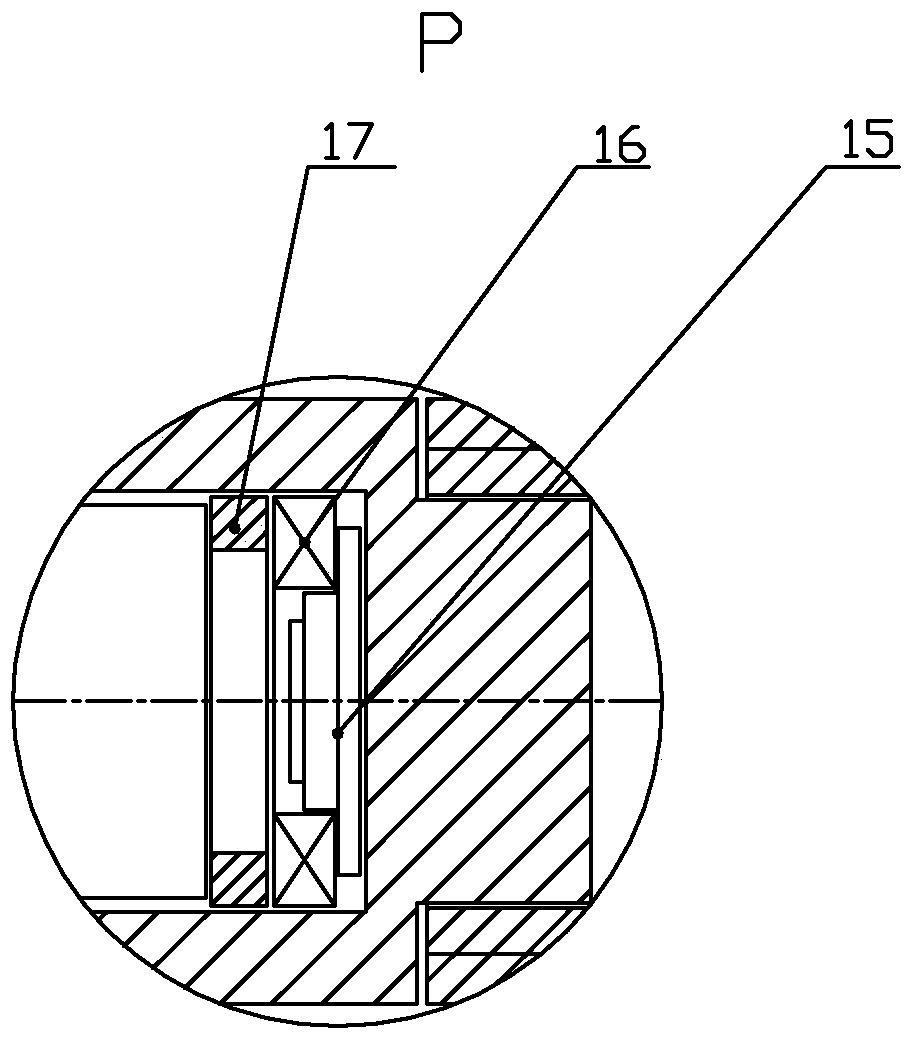

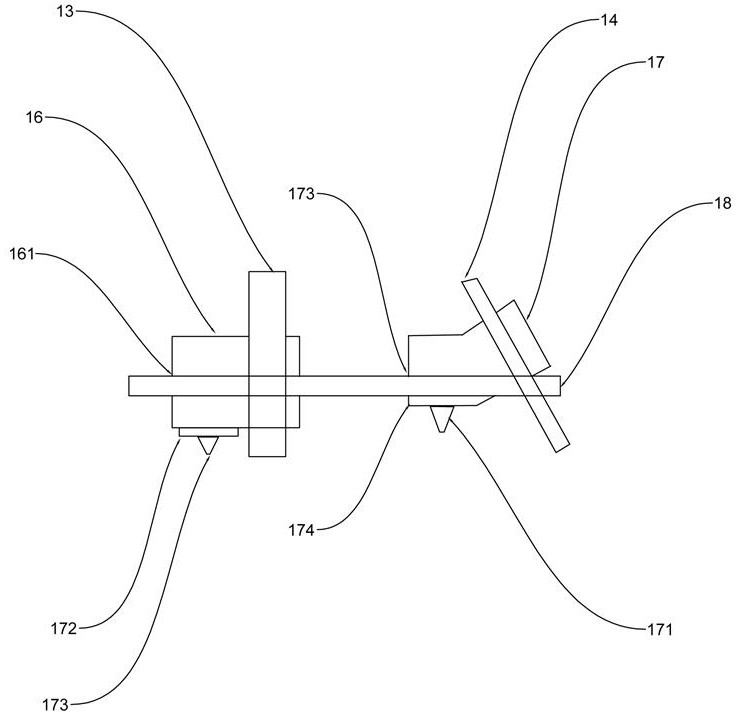

Mechanical puller for disassembling impellers and balance plates

The invention relates to a mechanical puller for disassembling impellers and balance plates. The problem of lacking of a tool capable of effectively disassembling the balance plates, balance disks and the impellers at present is solved. Two impeller disassembling devices are arranged in a symmetrical mode according to a central axis of the impellers, each pulling plate is located between the corresponding first-stage impeller and first-stage pump section, one end of each connecting bolt is connected with the corresponding pulling plate in a threaded mode, each pulling plate makes close contact with one end face of the corresponding first-stage impeller through a first lock nut arranged on the corresponding connecting bolt, the other end of each first lead screw is installed on a corresponding connecting plate in a penetrating mode and locked through a second lock nut, one end of each head jackscrew is matched with one end of a corresponding ejector bush machined with a shoulder, each head jackscrew is installed in the center of the corresponding connecting disk in a penetrating mode and connected with the connecting disk in a threaded mode, and each balance plate is fixedly connected with the corresponding connecting plate through a second lead screw and a third lock nut. The mechanical puller is used for disassembling the impellers and the balance plates.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

Pipeline cutting machine for water conservancy project

InactiveCN111843028AUniform force pointPrevent slidingTube shearing machinesShearing machine accessoriesElectric machineryStructural engineering

The invention discloses a pipeline cutting machine for a water conservancy project. The pipeline cutting machine structurally comprises a motor, a fixing device, a fixator and a control switch, wherein the fixing device is provided with a supporting mechanism, a rotating mechanism, a supporting rod and a fixing base, and two supporting blocks are distributed on the lower surface of a circular pipeline in a left-right mode, so that when an arc-shaped plate is compressed by the circular pipeline, a gap is generated between the supporting blocks, the effect of uneven stress points of the arc-shaped plate is achieved, the stress points of the circular pipeline are prevented from being too even, the circular pipeline is prevented from sliding, a rubber block drives a rotating block to compressa spring downwards, the effect of allowing the circular pipeline to pass through is achieved, a sliding ball slides on the inner side of a clamping ring by manually rotating a rotating rod, then a rotating ring can rotate reversely, the circular pipeline can be disengaged, the sliding ball is clamped to the inner side of the clamping ring when rotation is stopped, the rotating mechanism is distributed at the upper end of the supporting mechanism, the circular pipeline is fixed through a contact point, the situation that the outer side of the circular pipeline slides easily due to vibration isprevented, and cutting unevenness is avoided.

Owner:北京艾雪奥康信息咨询有限公司

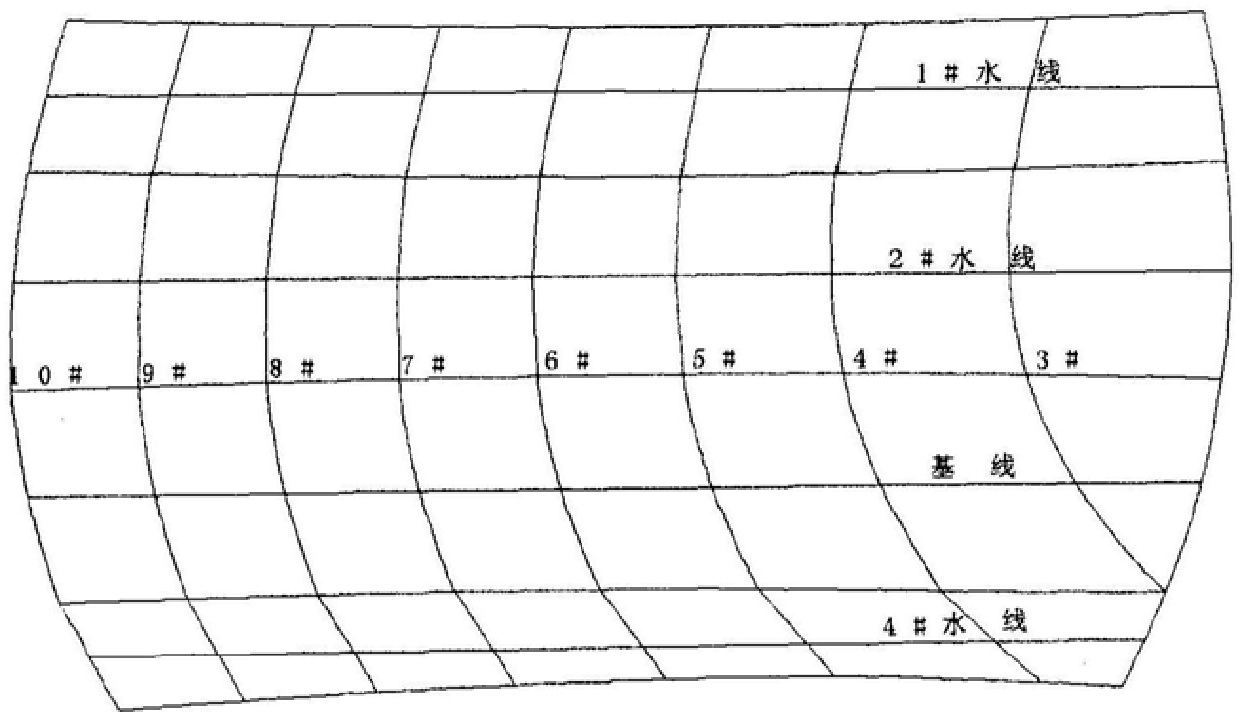

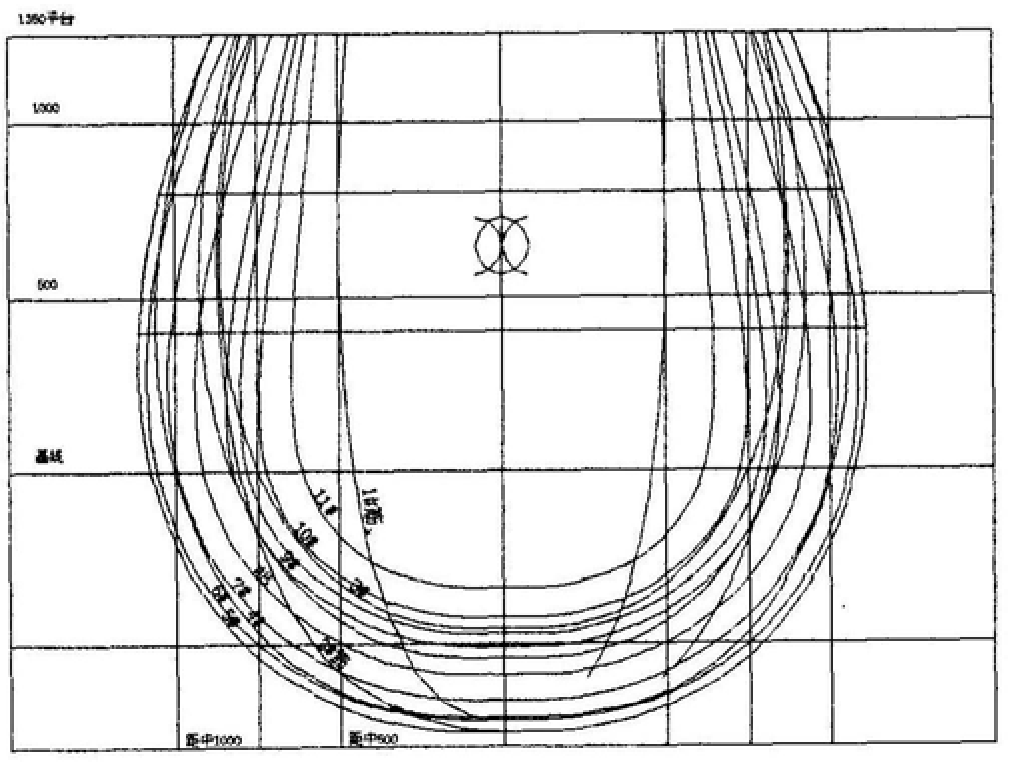

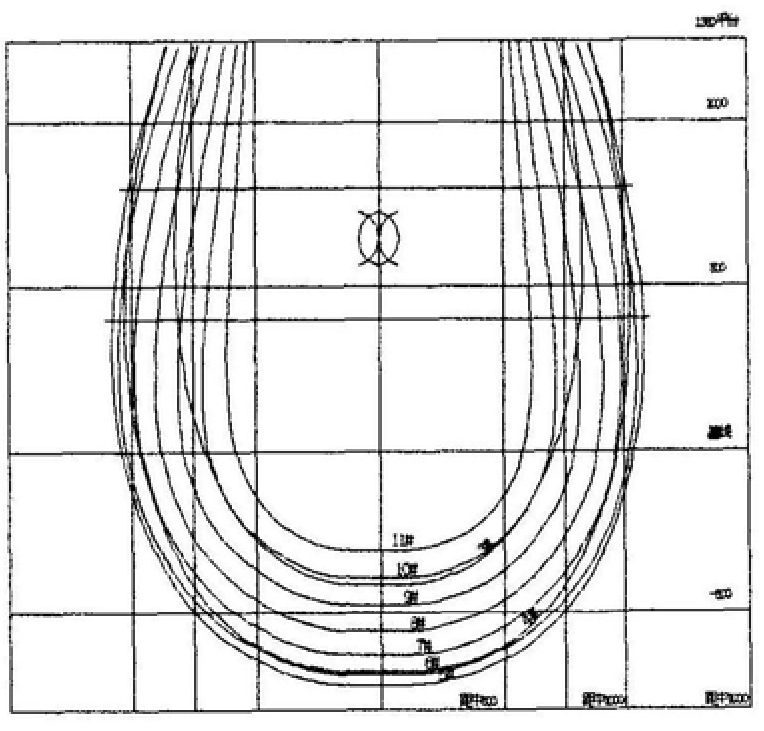

Manufacturing method of titanium alloy ship bulbous bow inner hull

ActiveCN106507746BHigh strengthConsistent spacingHull stemsVessel partsMomentumThree-dimensional space

The invention discloses a manufacturing method for the bulbous bow inner hull of a titanium alloy ship, which comprises the following steps: positioning the inner hull linearly normal to the vertical outer shell; fixing the distance in the three-dimensional space of the tire frame of the inner shell; The method adopted in the present invention can ensure the accuracy of the inner shell molding line, balance the stress points where the inner and outer shells connect, and increase the strength of the shell. The linear normal direction of the inner shell is positioned vertically to the outer shell so that the distance between the inner and outer shells is basically consistent. The tire frame of the inner casing is fixed in three-dimensional space, which effectively controls the difference in curvature of the fan-shaped surface with different widths and heights, and improves the accuracy of coordinate values in different spaces. Implement the combined expansion of parts on the grid of the inner shell, so that the expansion momentum of the shell can be adjusted to be basically the same, and the encrypted waterline and the small straight section of the rib head can improve the sampling rate of the external dimensions of the parts and the curvature of the line shape. The tightness of the structural joints is also increased.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Garment cloth ironing device

InactiveCN108755059AIrons evenly and quicklyImprove work efficiencyIroning apparatusTextiles and paperEngineeringLinear motor

The invention discloses a garment cloth ironing device, and relates to the technical field of garment cloth processing. The garment cloth ironing device comprises a base, wherein a groove is formed inthe right side of the base; the bottom of the groove is fixedly connected with a first linear motor module; a first slide rail is arranged at the lower end of the first linear module; the upper end of the first linear motor group is provided with a first slide table; the first slide rail is glidingly connected with the first slide table; the top of the first slide table is fixedly connected witha work table; clamp plates are fixedly connected with the top of the left and right ends of the work table; fast press tongs are fixedly connected onto the top of the clamp plate. The garment cloth ironing device has the advantages that through the arrangement of the first linear module, the second linear module and the air cylinder, the advantages of uniform and fast ironing and high work efficiency are realized; the air cylinder can be used for regulating the height of an electric iron; the work table can leftwards and rightwards move through the first linear motor module; the electric ironcan forward and backward move through the second linear module, so that the garment cloth can form the comprehensive ironing; the work efficiency is effectively improved.

Owner:湖南浚林服饰有限公司

Connected graphite crucible applied to producing vanadium-nitrogen alloy products

The invention discloses a connected graphite crucible applied to producing vanadium-nitrogen alloy products. The connected graphite crucible comprises a crucible body and a push plate. The crucible body and the push plate are of an integrated structure, wherein the crucible body and the push plate are perpendicular to each other and are coaxially connected. A coaxial crucible cavity is formed in the crucible body, and a coaxial push plate cavity is formed in the push plate. The top of the crucible cavity is flush with the top of the crucible body, the bottom of the crucible cavity is communicated with the top of the push plate cavity, and the bottom of the push plate cavity is located between the bottom of the crucible body and the bottom of the push plate. Preferably, the crucible body, the crucible cavity, the push plate and the push plate cavity are all cuboids. Both the crucible body and the push plate are made of graphite. By the aid of the design, the uniformity of force-bearing points can be guaranteed when the push plate and the crucible body are stressed, the defects such as front-back arching caused by dislocation are overcome, and no gas layer separation exists in the connecting position of the crucible body and the push plate. Heat conduction efficiency is high, the service life is long, and batch manufacturing is easy.

Owner:湖北晶洋科技有限公司 +1

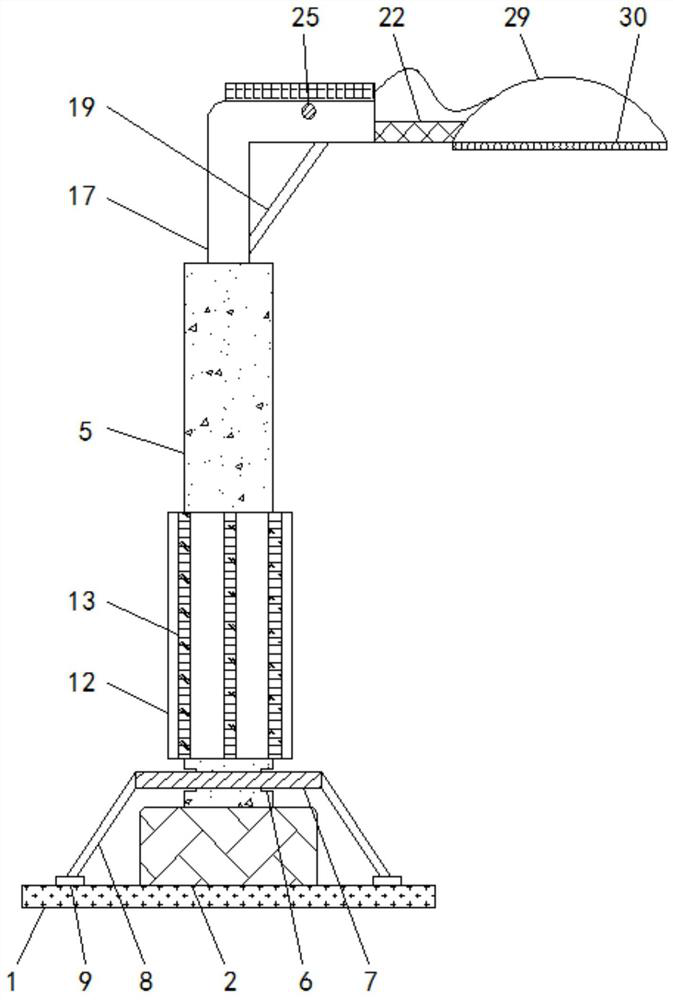

Adjustable windproof stable low-light level photoelectric street lamp

InactiveCN111678094AAdjustable irradiation heightPrevent rolloverMechanical apparatusLighting support devicesElectric machineEngineering

The invention relates to the technical field of photoelectric street lamps, and discloses an adjustable windproof stable low-light level photoelectric street lamp which comprises a base. According tothe adjustable windproof stable low-light level photoelectric street lamp comprises a street lamp body, a groove and a bearing are arranged on a supporting table, primary fixation of a lamp post is realized, a supporting ring, a supporting rod and a fixing block are arranged, the lamp post is movably connected with the base, by a first electric motor, the lamp post is directly driven to rotate inthe bearing, therefore, the irradiation direction of the whole photoelectric street lamp is rotated. By a second electric motor, a threaded rotating rod can be driven to rotate, a sleeve rod is drivento move up and down, so that illumination height of the whole photoelectric street lamp is adjusted to adapt to multiple illumination requirements, and through the arrangement of a windproof barrel,when the lamp post is subjected to lateral strong wind, the wind can be blown into a strip-shaped groove to drive the windproof barrel to rotate on the outer side of the lamp post, lateral thrust generated by the strong wind is offset, and the purposes of being adjustable and good in windproof effect are achieved.

Owner:江苏彩晶光电科技有限公司

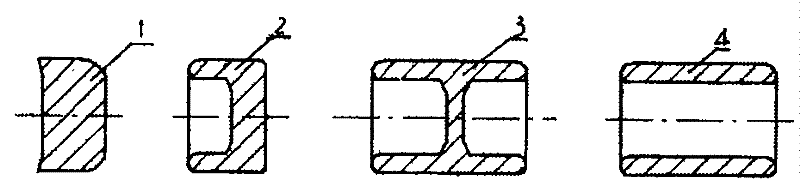

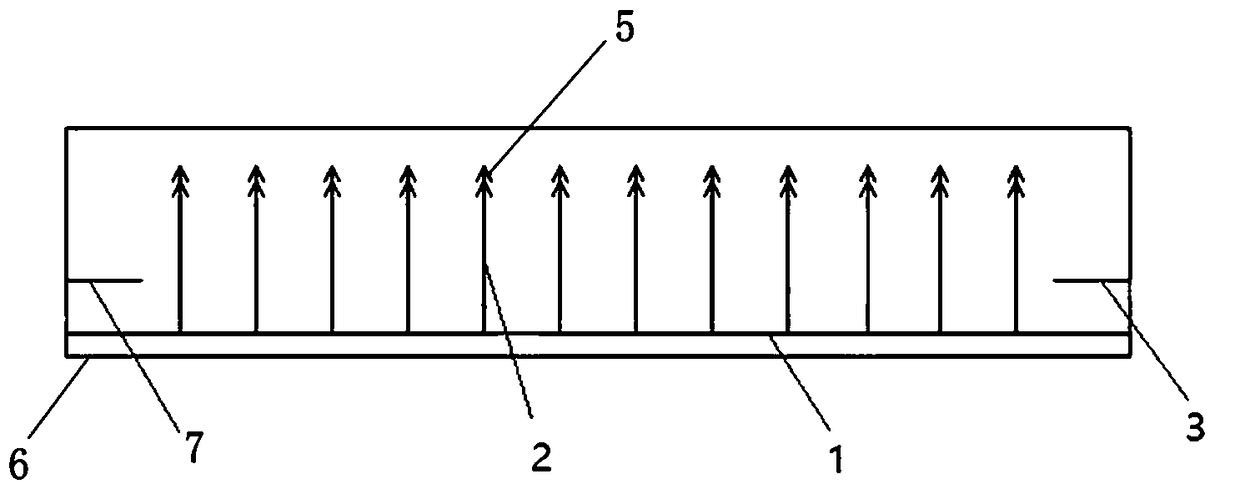

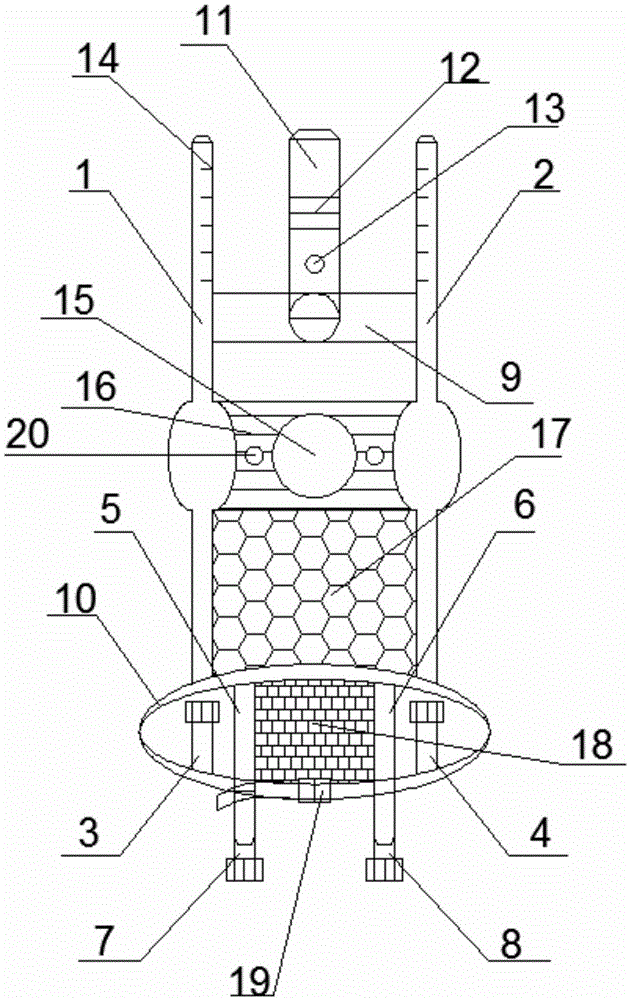

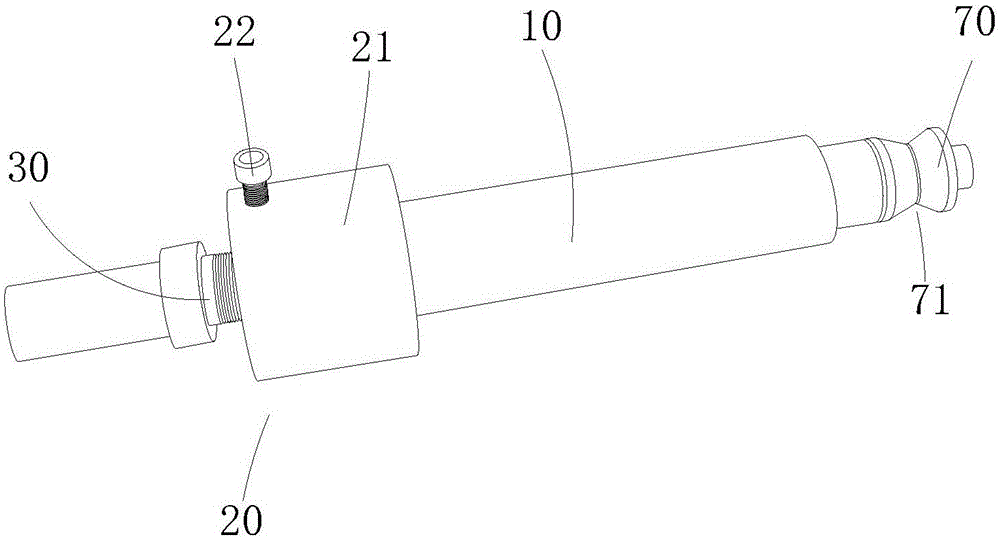

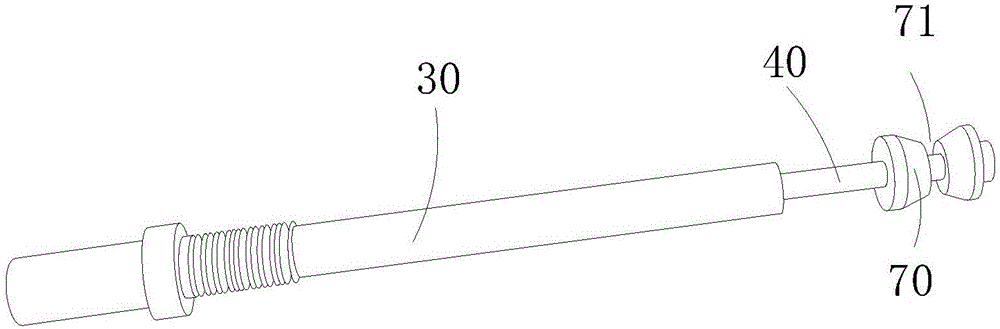

Cold heading forming process for seamless chain roller and punch pin head for cold heading forming bottom punching

InactiveCN102228949AFlow to completeAvoid Damage DefectsForging/hammering/pressing machinesPunchingCombined use

The invention discloses a cold heading forming process for a seamless chain roller and a punch pin head for cold heading forming bottom punching. The cold heading forming process for the seamless chain roller comprises the steps of feeding, cutting, flat heading, blank heading, inversion, head punching, inversion, secondary punching and bottom punching; the depth of the head punching after the blank heading and the inversion is controlled in a range of 2 to 5 millimeters; and the reserved bottom thickness of the secondary punching after the inversion is controlled in a range of 0.5 to 2 millimeters. The punch pin head for the cold heading forming bottom punching comprises a front head of a cylindrical surface, and the rear part of the front head (10) of the cylindrical surface of the punch pin head is a raised spherical surface (20). By combining the cold heading forming process and the punch pin head, one-time precise cold extrusion forming of workpieces can be finished, staggered metallographic structures in the metal and defective metallic plastic formed metal streamlines are repaired, and the mechanical property of a product is further improved.

Owner:JIXI HUANGSHAN IND

Tendon anti-adhesion membrane anastomat for strengthening tendon anastomosis stoma

The invention relates to a tendon anti-adhesion membrane anastomat for strengthening tendon anastomosis stoma. The anastomat comprises an annular housing with an opening, a membrane body and an anchornail; the membrane body is a narrow strip of biomaterial membrane, and the membrane body is uniformly provided with a plurality of micropores; the membrane body is divided into a guiding section anda bonding section in the longitudinal direction thereof, and a plurality of anchor nails are distributed on the inner side surface of the bonding section, the anchor nail is provided with a barb, andthe integral structure of the anchor nail and the barb is made of biological materials; the membrane body is wound in the open annular housing; the guiding section of the membrane body is placed outside the open annular housing; both sides of the annular housing with an opening are devices and are provided with guide grooves guiding to both sides of the membrane body. The inner annular surface ofthe opening annular housing is hollowed to accommodate the position of the anchor nails. The structure is simple, can quickly match the tendon connection, meet the requirement of normal activity of tendon after the tendon rupture surgery, reduce the tension of the tendon anastomosis; patients can immediately exercise after surgery; the risk of tendon adhesion is reduced; the clinical operation effect is improved and secondary surgery is avoided.

Owner:王志勇

Sand blasting technology for hardware

The invention discloses a sand blasting technology for hardware. The technology comprises the following steps: (1) preparing before sand blasting, namely, selecting related sand blasting devices and corresponding sand molds based on an instruction card; (2) sand blasting test, namely, performing pre-blasting test; opening a compressed air valve and a water valve; detecting whether air and water are leaked; and testing whether a blasting gun is capable of normally blasting sand; (3) sand blasting, namely, rotating the hardware to be subjected to sand blasting on a material plate at a position for sand blasting; closing a door of a sand blasting machine; and blasting sand; (4) washing, namely, washing the sand blasted hardware through clean water; soaking in an antirust solution for 5-6min;and blowing to dry through compressed air; and (5) inspecting, namely, inspecting the sand blasting quality of the hardware; and reworking unqualified products. According to the sand blasting technology for the hardware, the processes are simple and are reasonably and coordinately arranged; the roughness and uniformity of the hardware can be improved; the stressing points of the hardware are uniform; the corrosion resistance of the hardware is improved; the fatigue resistance of the hardware is high; and the service life of the hardware is long.

Owner:江苏东恒光电有限公司

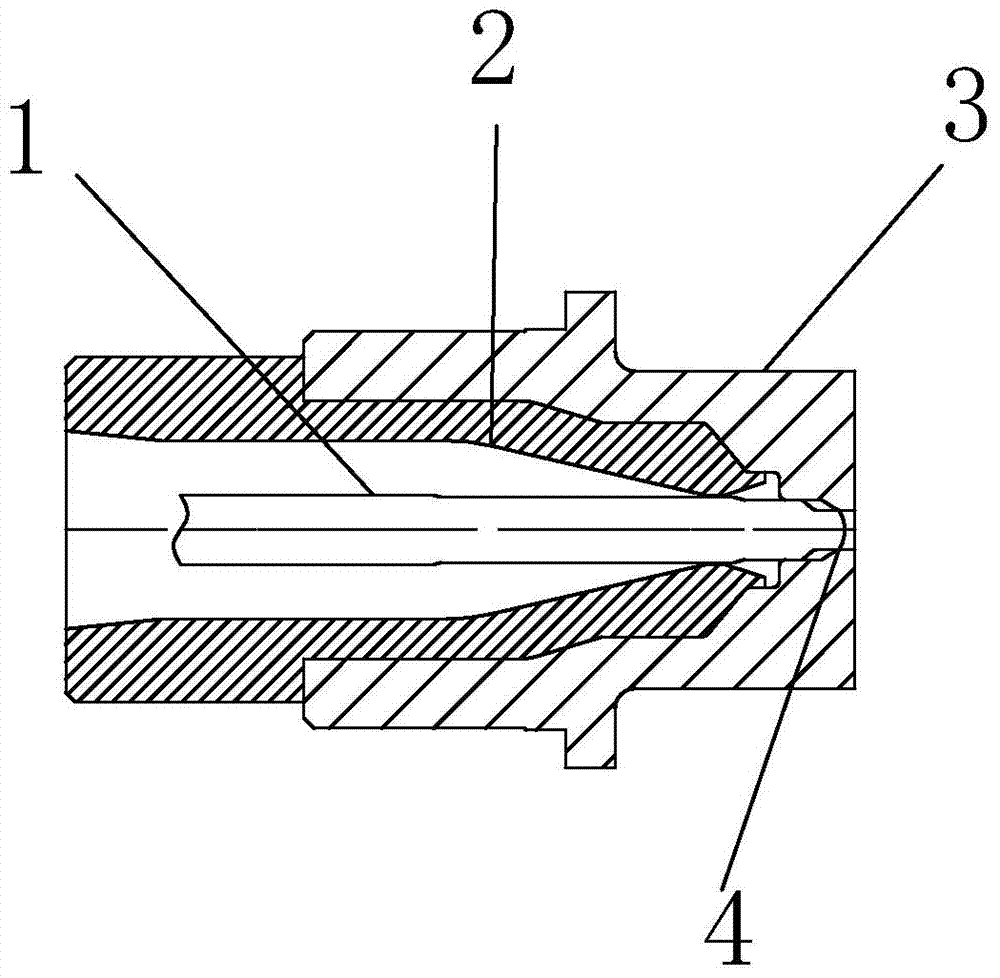

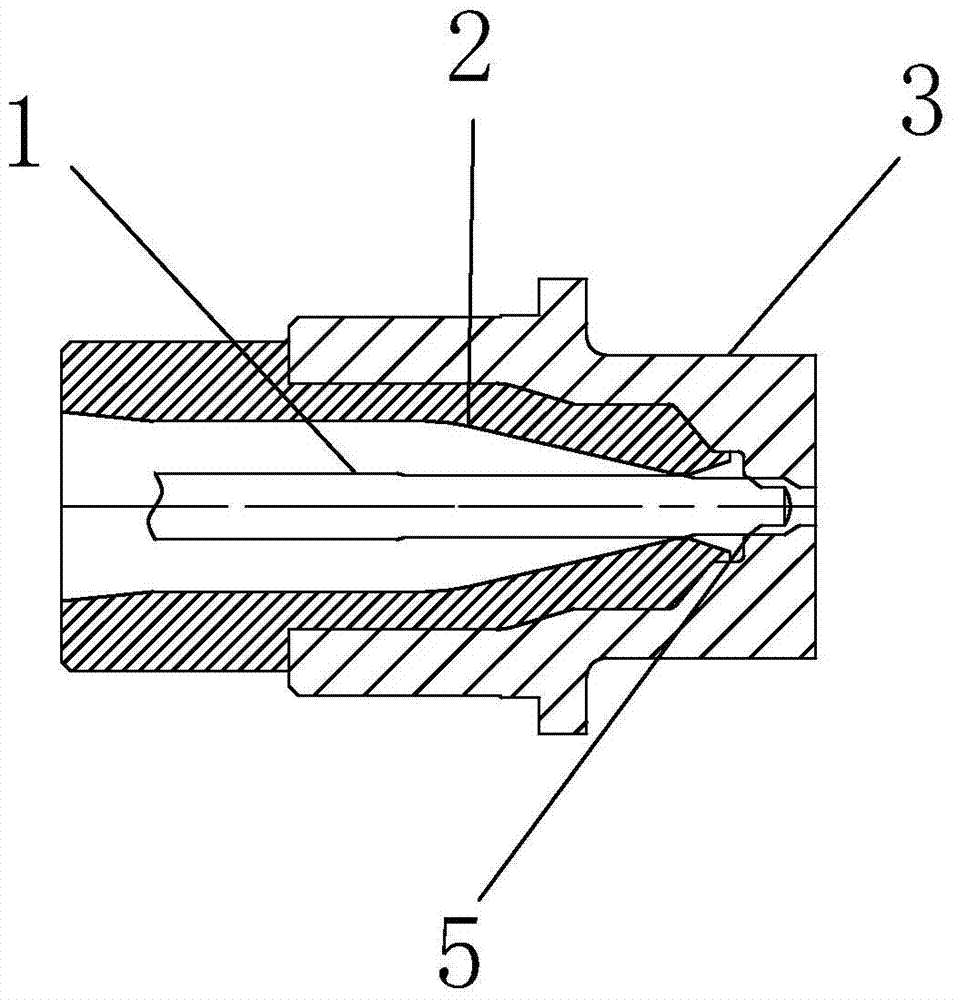

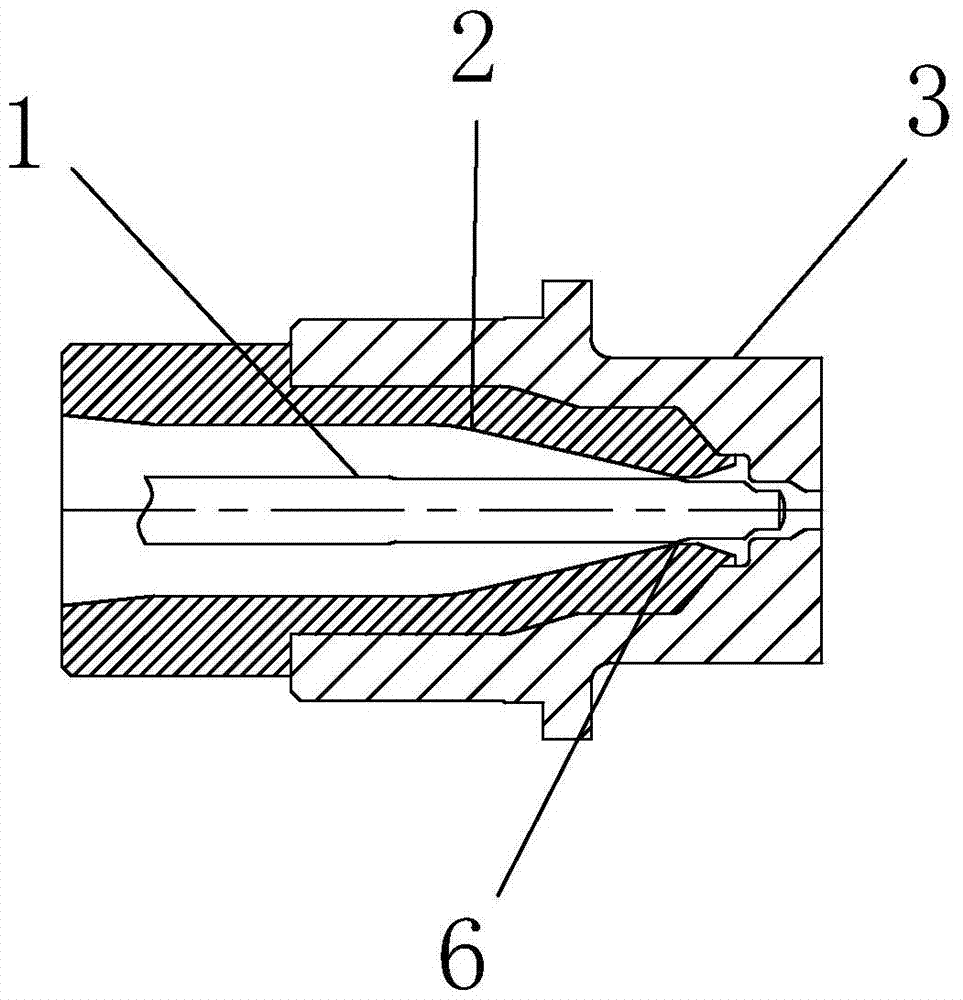

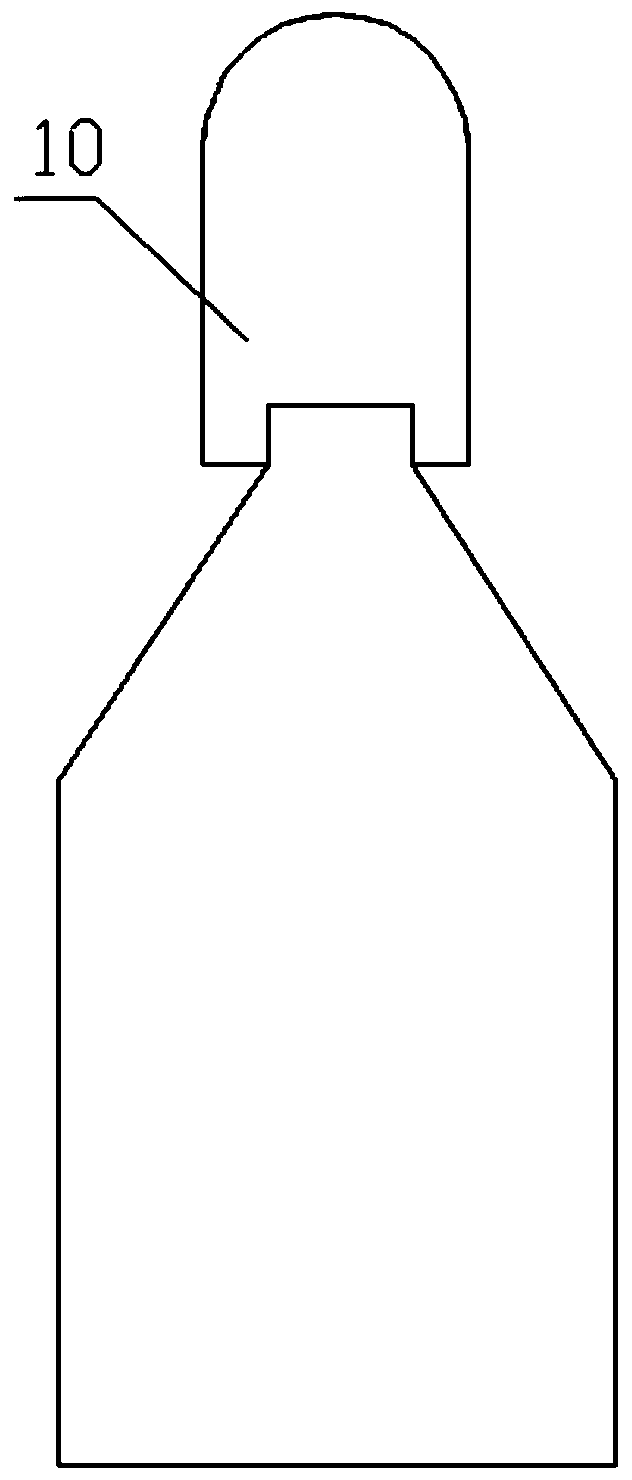

A pilot-operated valve needle sealing system

The invention discloses a pilot-operated type valve needle glue sealing system. The system comprises a valve needle, a core and a core cover. The core is arranged in the core cover. The valve needle is arranged in the core. A first step at the head of the valve needle is in a clearance fit relationship with a round glue gate of the core cover. The single edge of the fit gap has the size of 0.002-0.005mm. A second step of the valve needle is in a clearance fit relationship with a second step of the core cover and the single edge of the fit gap has the size of 0.01-0.02mm. A third step of the valve needle is in a clearance fit relationship with the core and the single edge of the fit gap has the size of 0.1-0.2mm. Through the pilot-operated type valve needle glue sealing system, stress points of the head of the valve needle and the round glue gate are uniform, the round glue gate is not changed into an elliptical structure, the valve needle and the round glue gate resist wear and have long service lives, the product glue gate is complete and burr or aberration around the glue gate is not produced.

Owner:SUZHOU HTS MOLD

Active positioning door rolling machine

InactiveCN106812454AAct as a driving forceOvercome the problem of explosive disassemblyDoor/window protective devicesExplosive forceClutch

The invention provides an active positioning door rolling machine. The machine comprises a reel assembly and two supports, wherein the two ends of the reel assembly are arranged on the two supports respectively. The reel assembly is internally provided with one or more non-rotating parts, and the non-rotating parts are fixedly arranged on one of the supports, so that the non-rotating parts do not rotate relative to the supports; the machine is characterized in that a normally closed clutch mechanism is arranged between one fixedly arranged support and one non-rotating part, when the normally closed clutch mechanism is in an open state, the non-rotating parts can rotate relative to the fixedly arranged support, and an inner power system of the reel assembly does not motivationally drive a reel any more. When a motor and a gearbox or other power parts or transmission components within the reel assembly can not work normally, the normally closed clutch mechanism can be opened, an emergency power mechanism or an external power mechanism drives the reel assembly to rotate, a door curtain is then driven to move up and down at any time, and the problem that traditional similar products need to be dissembled with explosive force is solved.

Owner:漳州市亿锦进出口有限公司

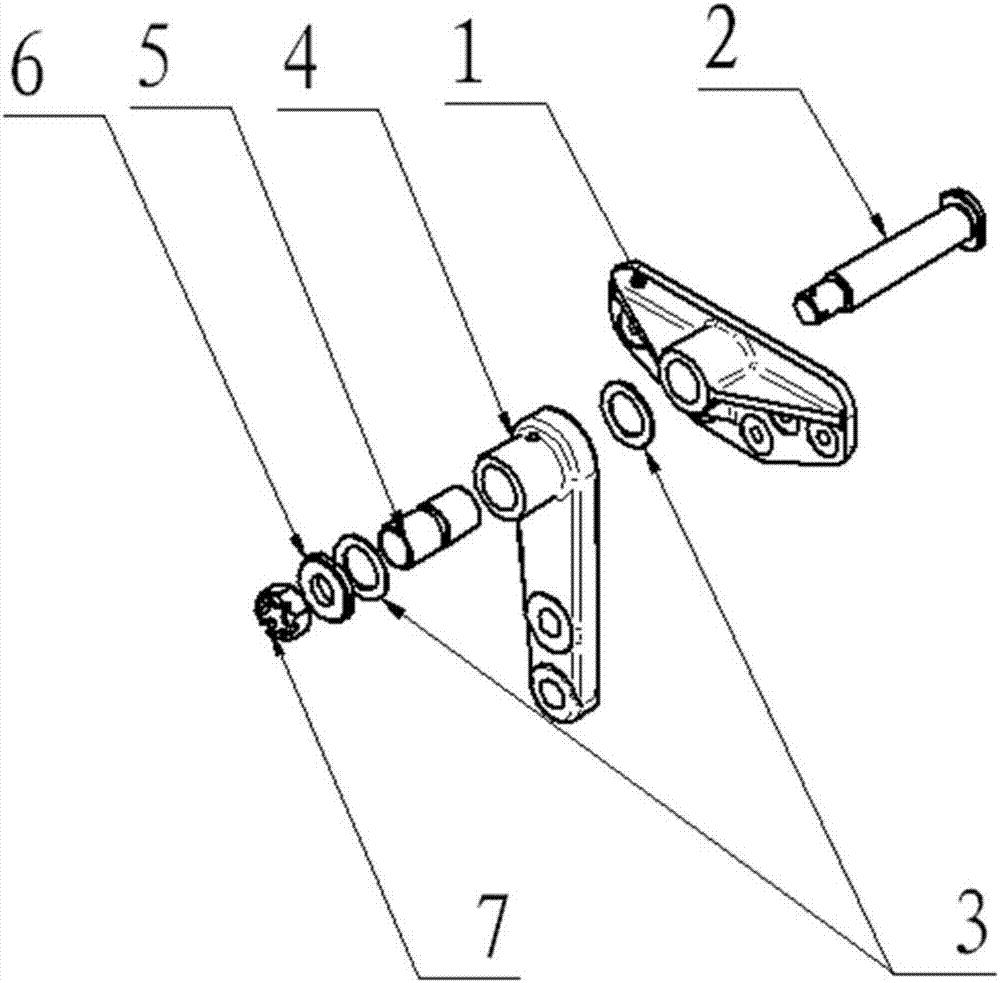

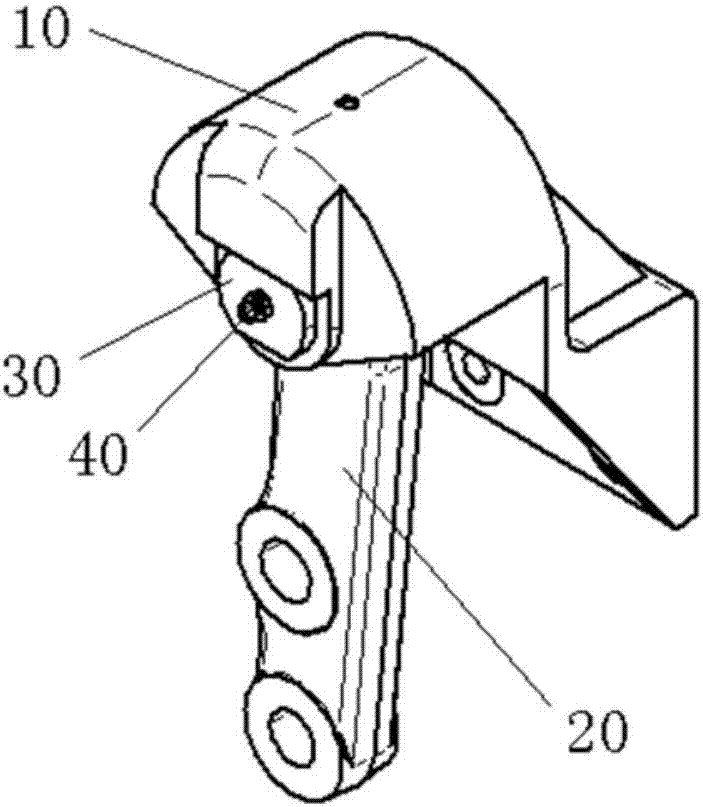

Automobile steering transition rocker arm assembly

The invention relates to an automobile steering transition rocker arm assembly which comprises a rocker arm bracket, a transition rocker arm, a rocker arm shaft, a lining and a fixing nut. A rocker arm shaft perforation is formed in the upper end of the transition rocker arm; the lining is fixed in the rocker arm shaft perforation; the rocker arm bracket comprises a rocker arm shaft connecting part and a rocker arm bracket fixing part; an opening is formed in the lower end of the rocker arm shaft connection part; the upper end of the transition rocker arm is movably arranged in the opening; the rocker arm shaft penetrates through a rocker arm shaft through hole and the lining and then is fastened through a fixing bolt; the rocker arm bracket fixing part is fixedly connected with the inner side wall of the rocker arm bracket; and a rocker arm bracket mounting hole is formed in the rocker arm bracket fixing part. According to the automobile steering transition rocker arm assembly, by improving the rocker arm bracket structure, the two ends of the rocker arm shaft are subjected to the same supporting force, the force-bearing points of the rocker arm shaft and the lining are basically uniform, the abrasion speed between the rocker arm shaft and the lining is reduced, and deformation of the rocker arm shaft is relieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Multipurpose safety belt and use method thereof

The invention relates to a multipurpose safety belt and a use method thereof. The multipurpose safety belt comprises shoulder belt bodies, a chest belt body, a waist belt body and leg belt bodies. The shoulder belt bodies comprise the left shoulder belt body and the right shoulder belt body. The left shoulder belt body comprises a front left shoulder belt unit and a rear left shoulder belt unit, and the right shoulder belt body comprises a front right shoulder belt unit and a rear right shoulder belt unit. The chest belt body is fixed between the rear left shoulder belt unit and the rear right shoulder belt unit. The lower end of the front left shoulder belt unit, the lower end of the rear left shoulder belt unit, the lower end of the front right shoulder belt unit and the lower end of the rear right shoulder belt unit are all connected with the upper edge of the waist belt body. The lower edge of the waist belt body is connected with the leg belt bodies. The leg belt bodies comprise the left leg belt body and the right leg belt body. The left leg belt body comprises a front left leg belt unit and a rear left leg belt unit, and the right leg belt body comprises a front right leg belt unit and a rear right leg belt unit. The multipurpose safety belt is simple in structure and convenient to use; a buffering belt body is arranged to guarantee that stress points are uniform in falling, and impact force is effectively absorbed; a back protection net and a buttock protection net are arranged to guarantee comfort, and personal safety of operators is effectively guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

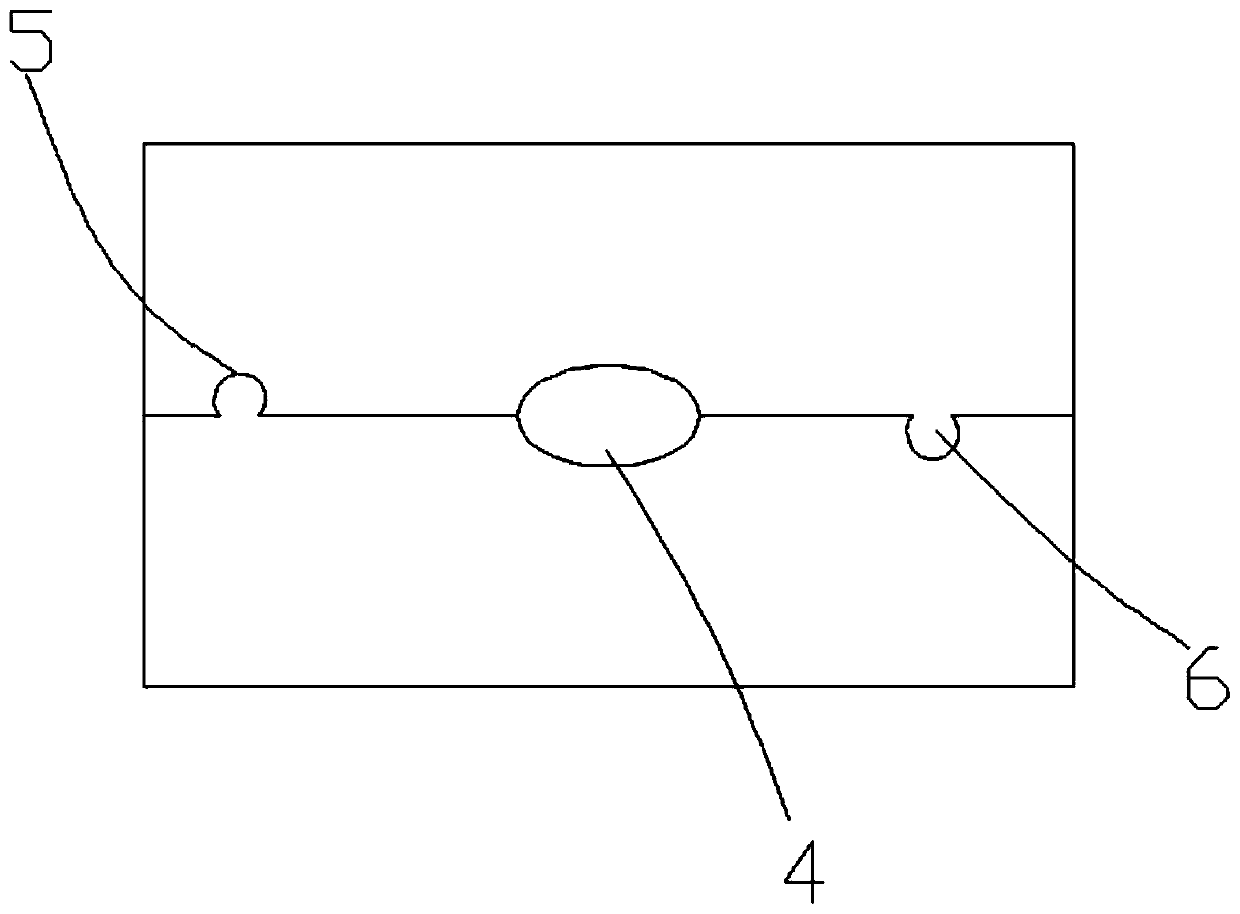

Thermocouple combined brick with deformation damage preventing function

InactiveCN110982975AFor installationUniform force pointThermometer detailsThermometers using electric/magnetic elementsPhysicsEngineering

The invention relates to a thermocouple combined brick with a deformation damage preventing function, and belongs to the field of thermocouple combined bricks. The thermocouple combined brick with thedeformation damage preventing function is formed by splicing two thermocouple brick bodies, wherein the two thermocouple brick bodies are arranged in an up-and-down mode and are spliced with each other. According to the thermocouple combined brick with the deformation damage preventing function, the combined brick with an elliptical groove hole replaces an original reserved square hole, and the elliptical hole is prefabricated in the middle when a square brick is manufactured through firing to be used for mounting of the thermocouple.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

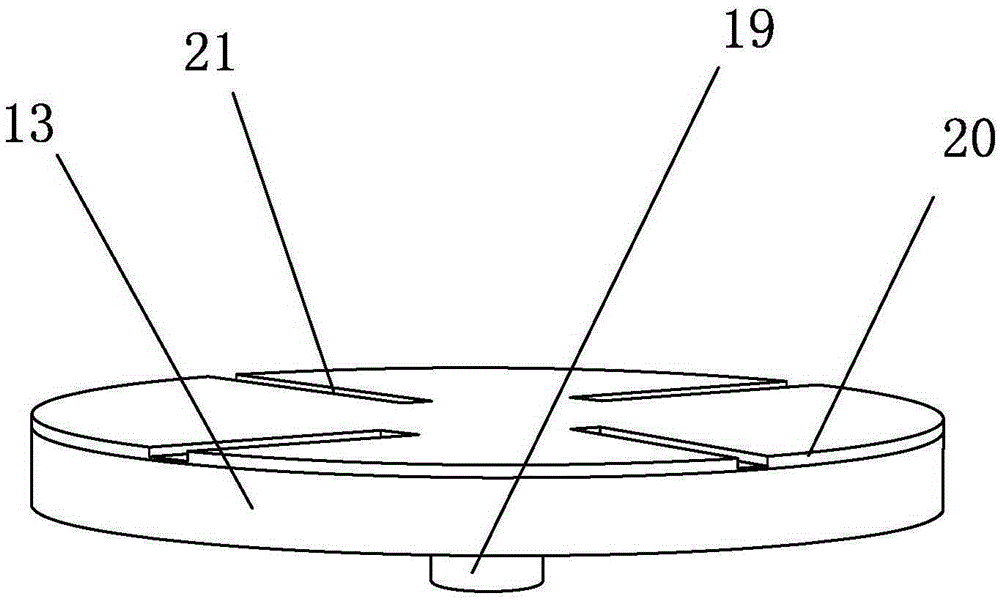

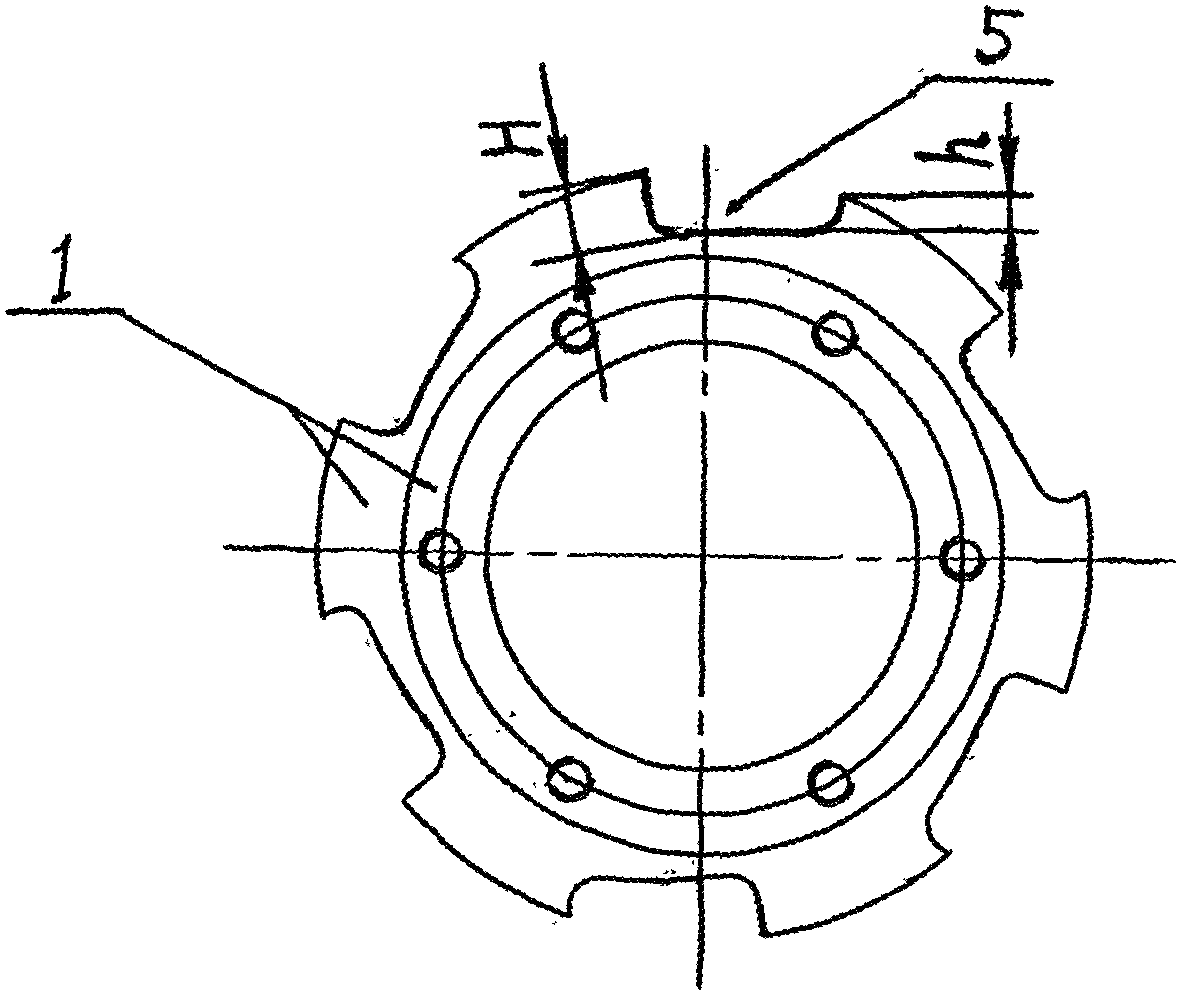

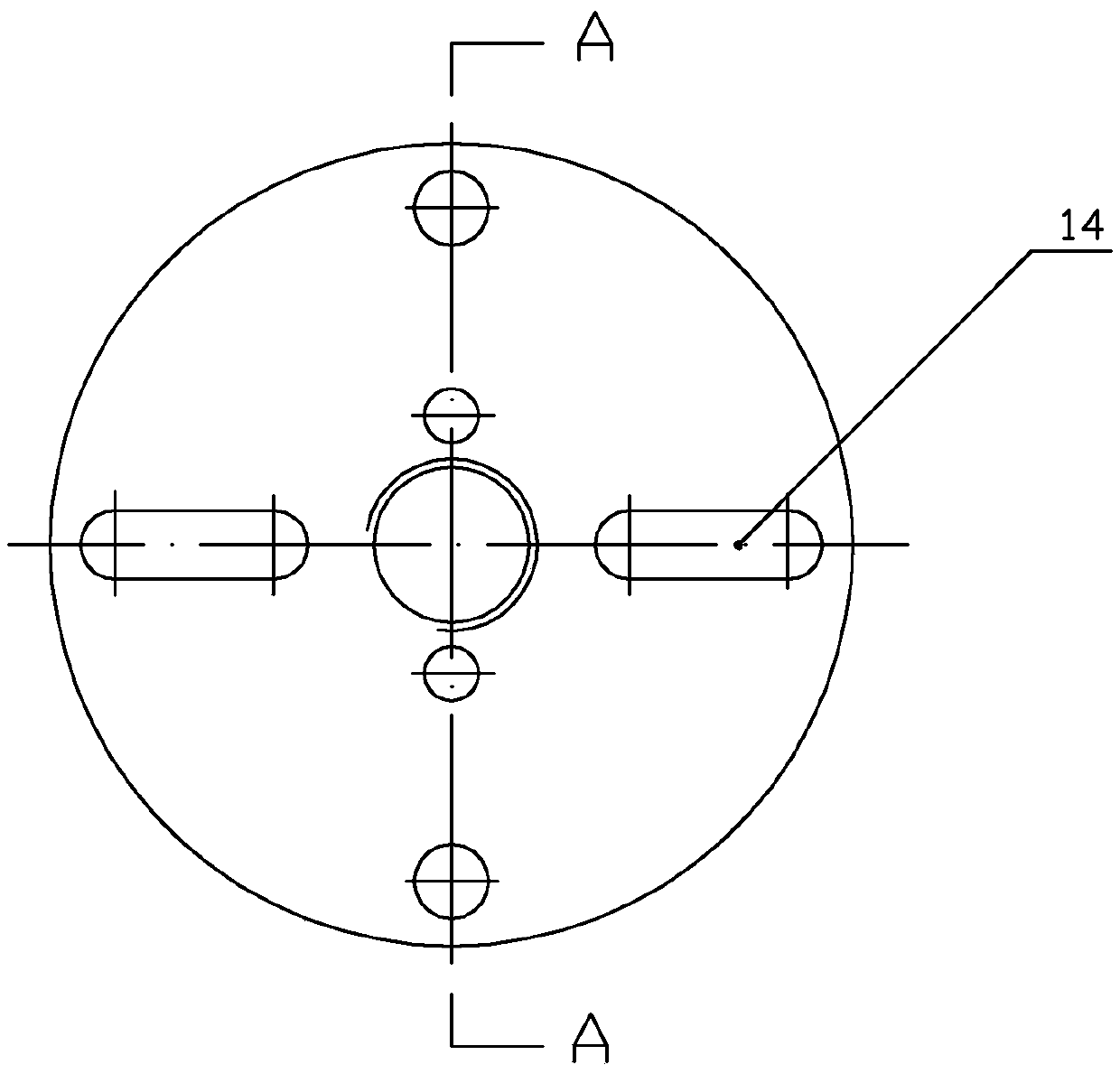

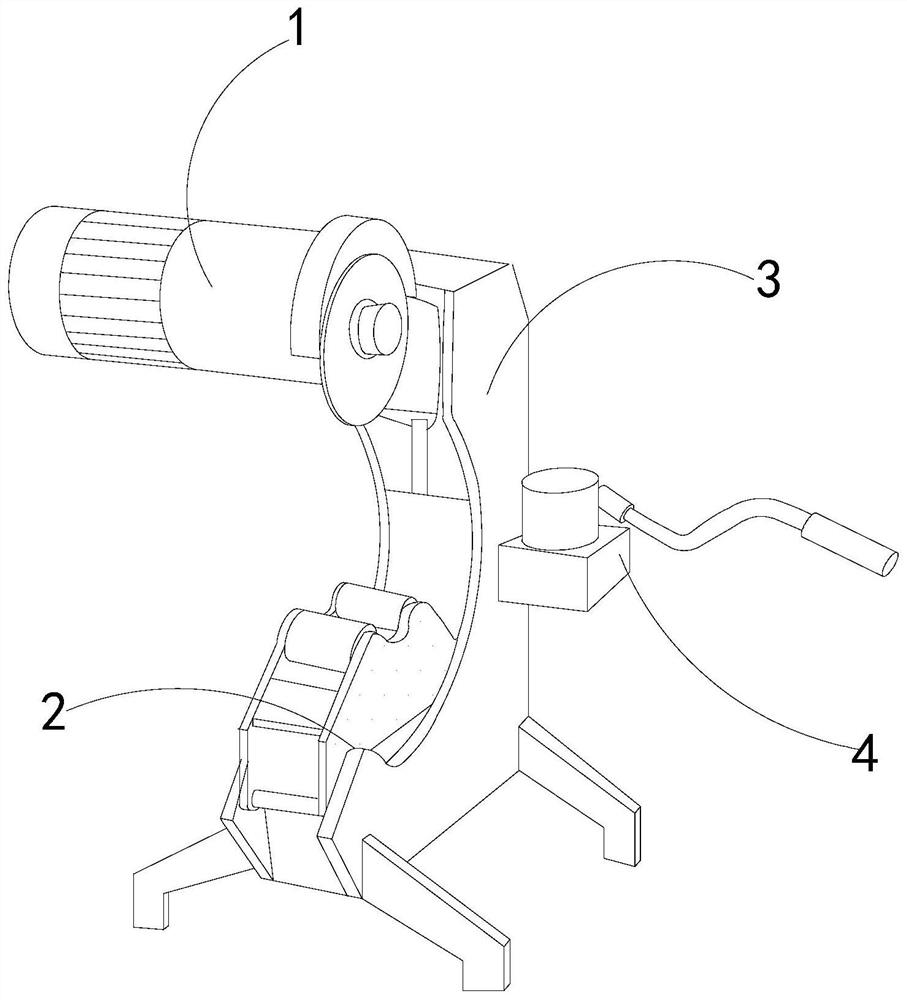

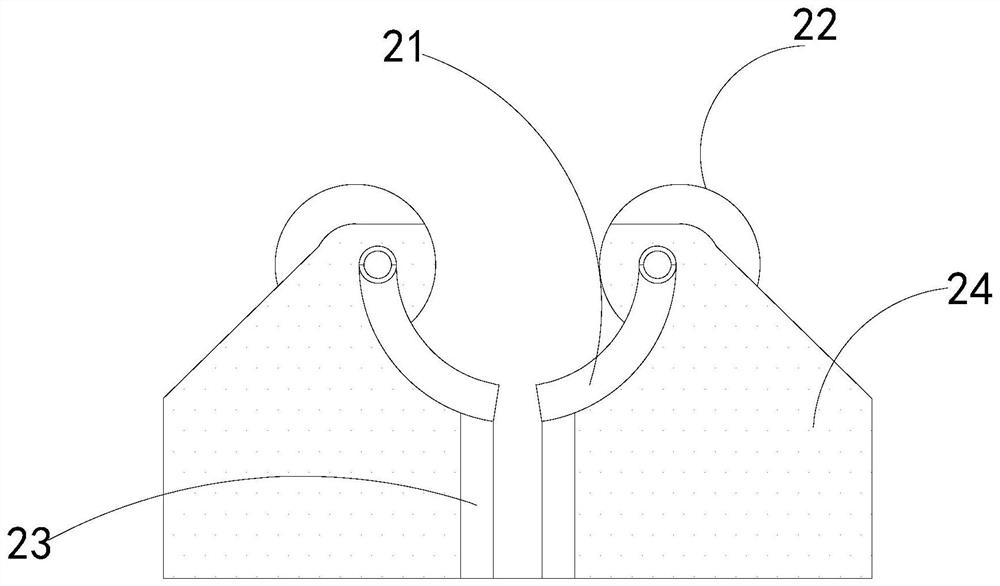

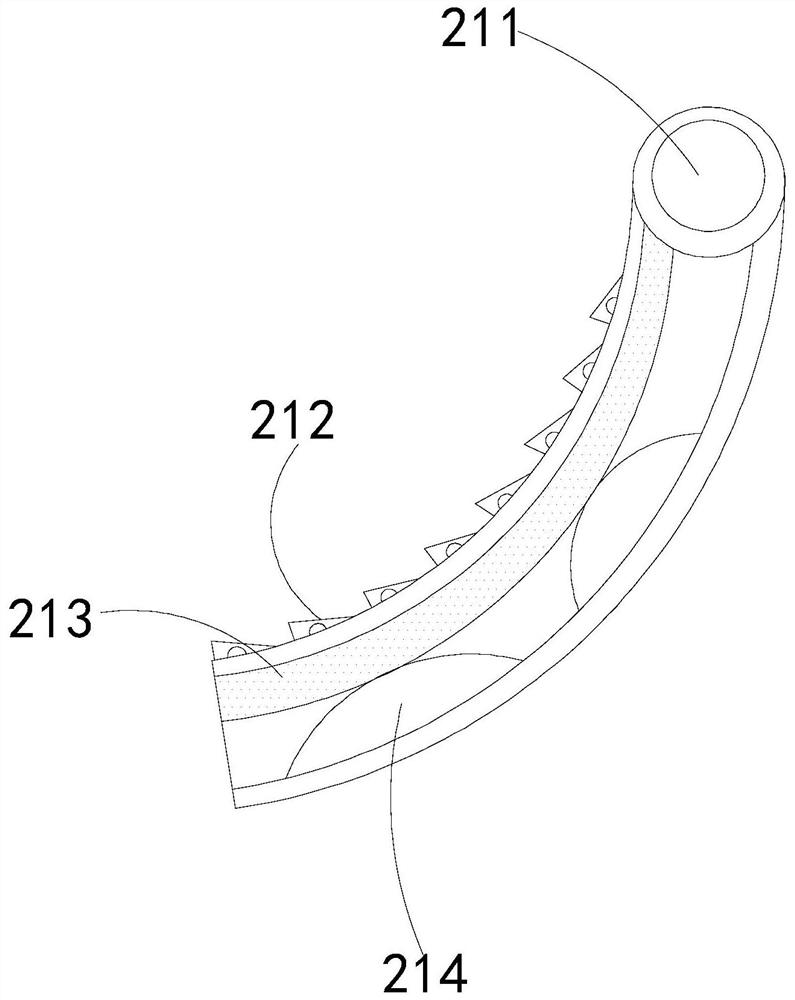

Mounting structure of scaling knife of fish killing machine

PendingCN110623054AStatus reply quicklyAvoid rubbing back and forthFish washing/descalingStress pointFish processing

The invention discloses a mounting mechanism of a scaling knife of a fish killing machine, belongs to the technical field of fish processing equipment, and solves the problems that existing return springs are uneven in stress, prone to abrasion and breakage and short in service life. The mounting mechanism comprises two fixing discs which are oppositely arranged, a mounting hole penetrating fixingdiscs in the axial direction is formed in the center of the two fixing discs, at least one scaling combination distributed on the axial peripheral side is arranged between the two fixing discs, and each scaling combination comprises a return spring which is arranged between the two fixing discs in a connection mode and extends in the axial direction, a fixed rotating shaft, scaling blades, a movable shaft, a limiting column and a spring pressing plate. By means of the structure, breakage caused by back-and-forth friction between the return spring and the movable shaft can be avoided, the stress points of the return spring are uniform, the structural stability is improved, the service life is prolonged, state recovery of the scaling blades after each action can be quicker, and the use performance of the fish killing machine using the scaling knife is further guaranteed.

Owner:龙泽良

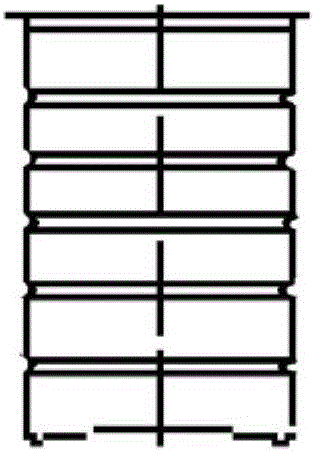

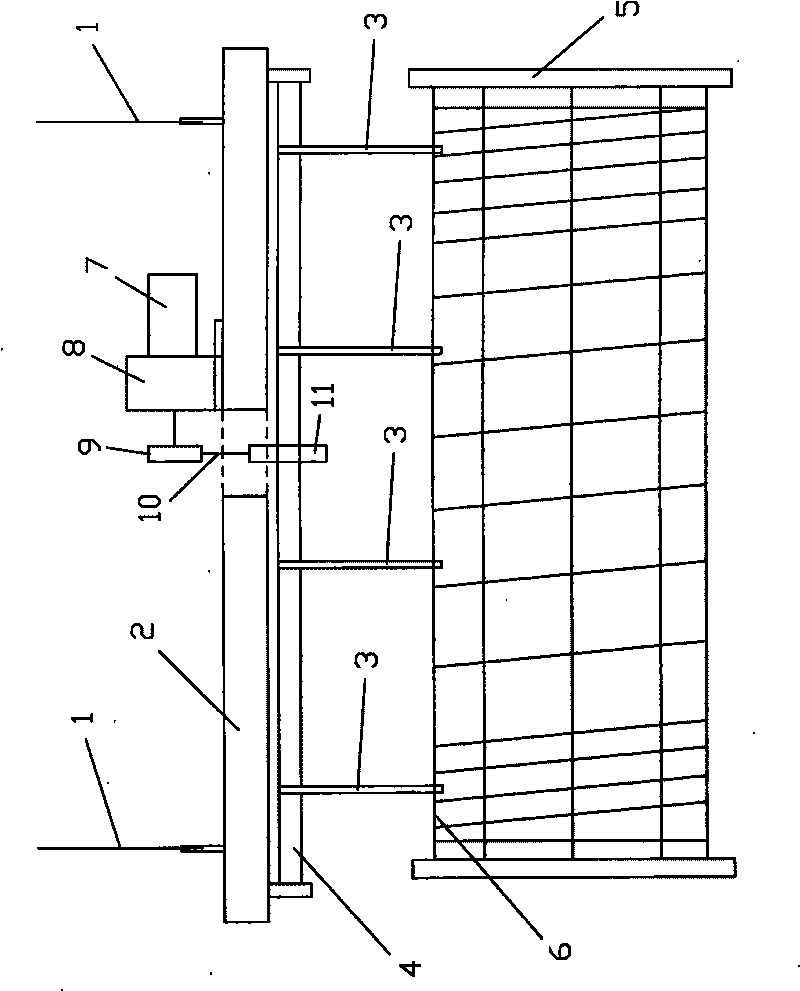

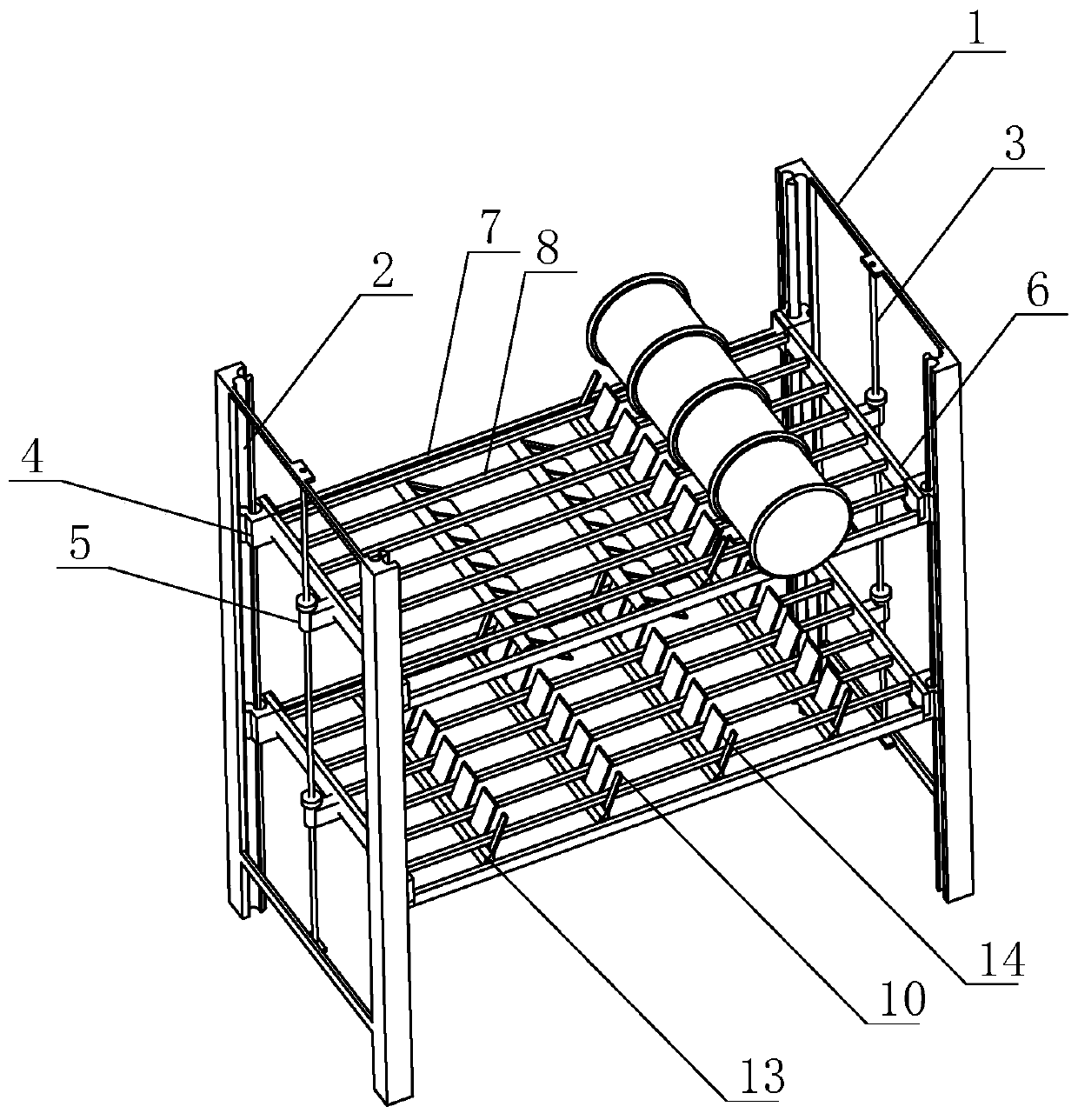

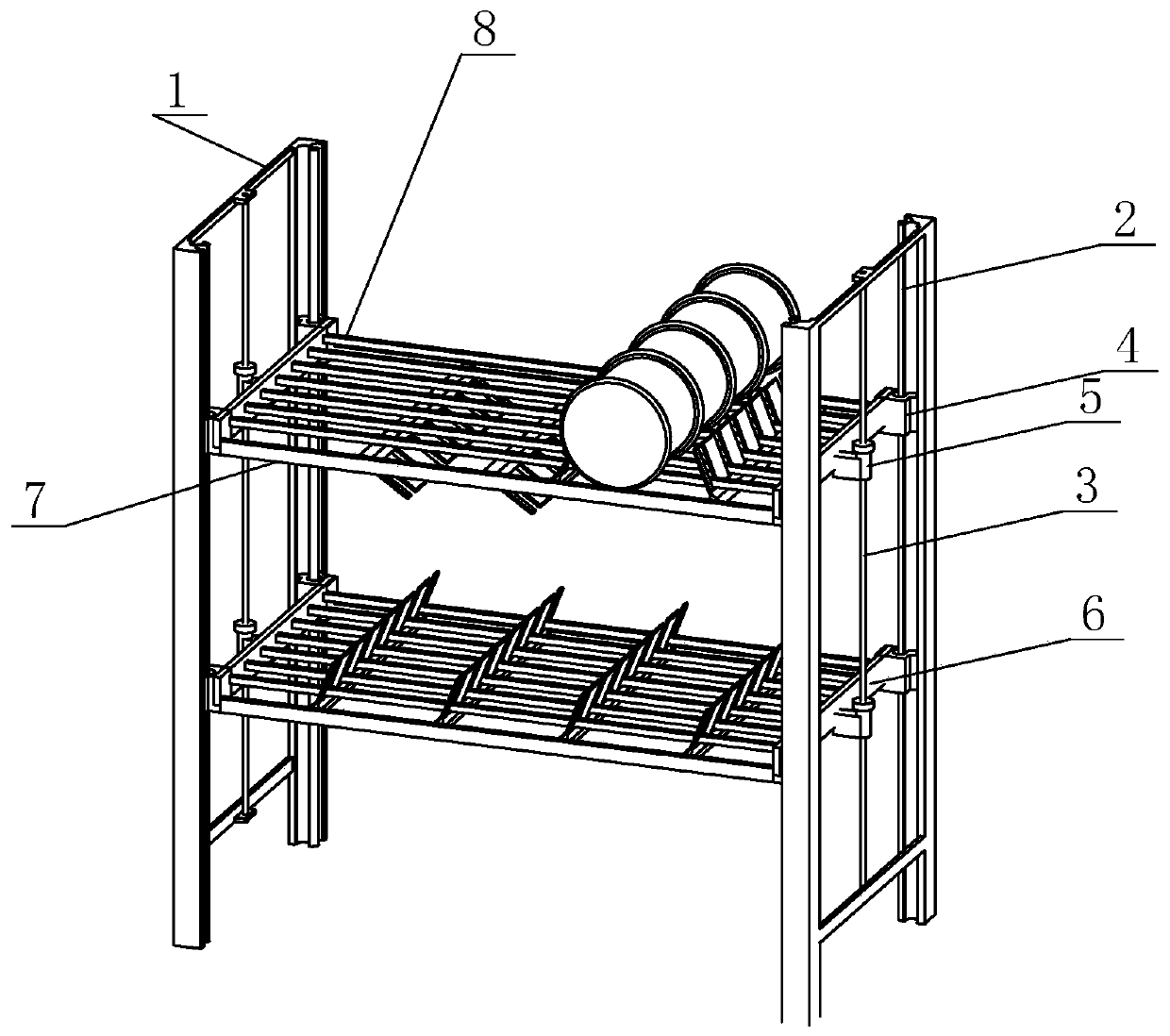

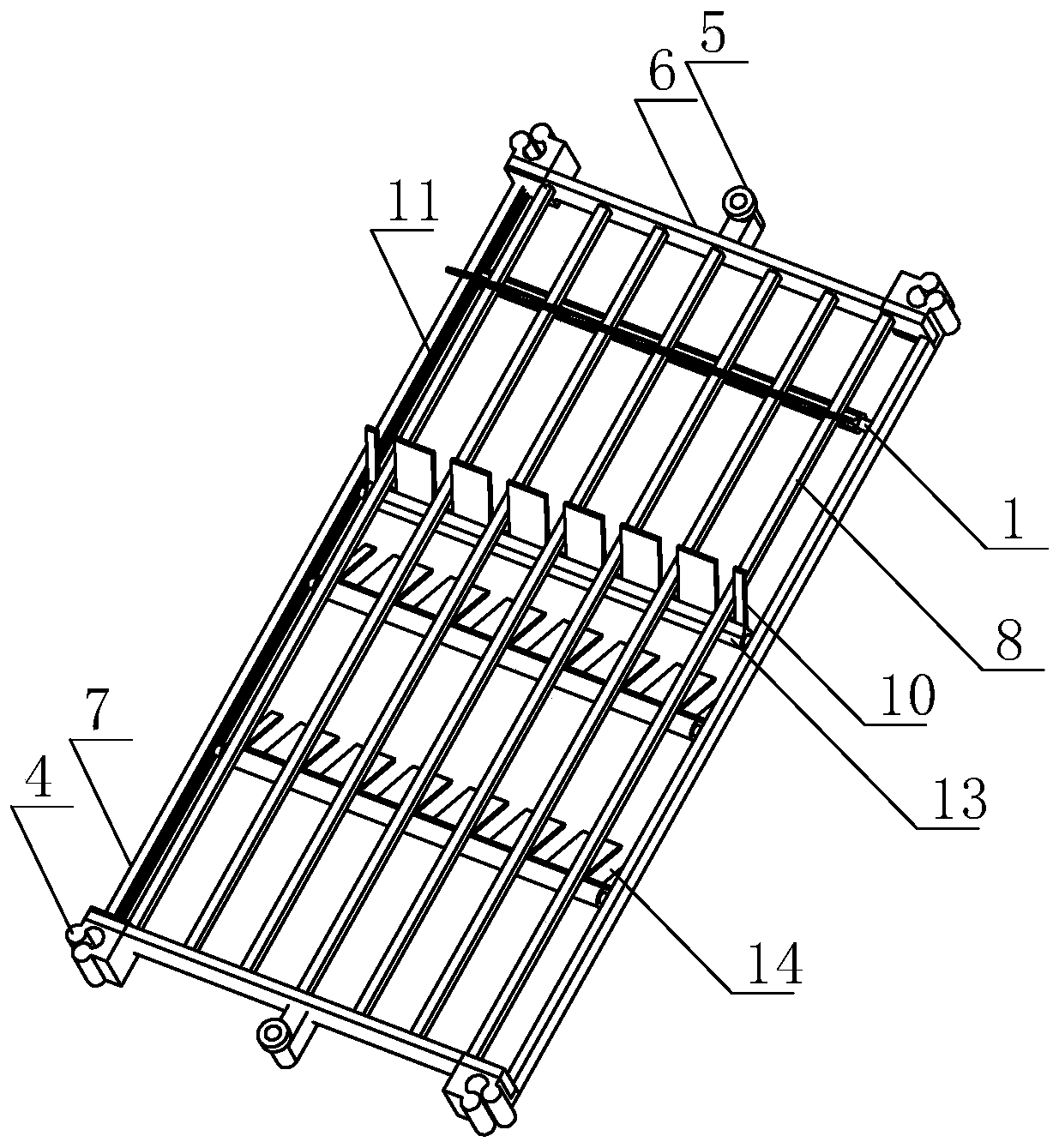

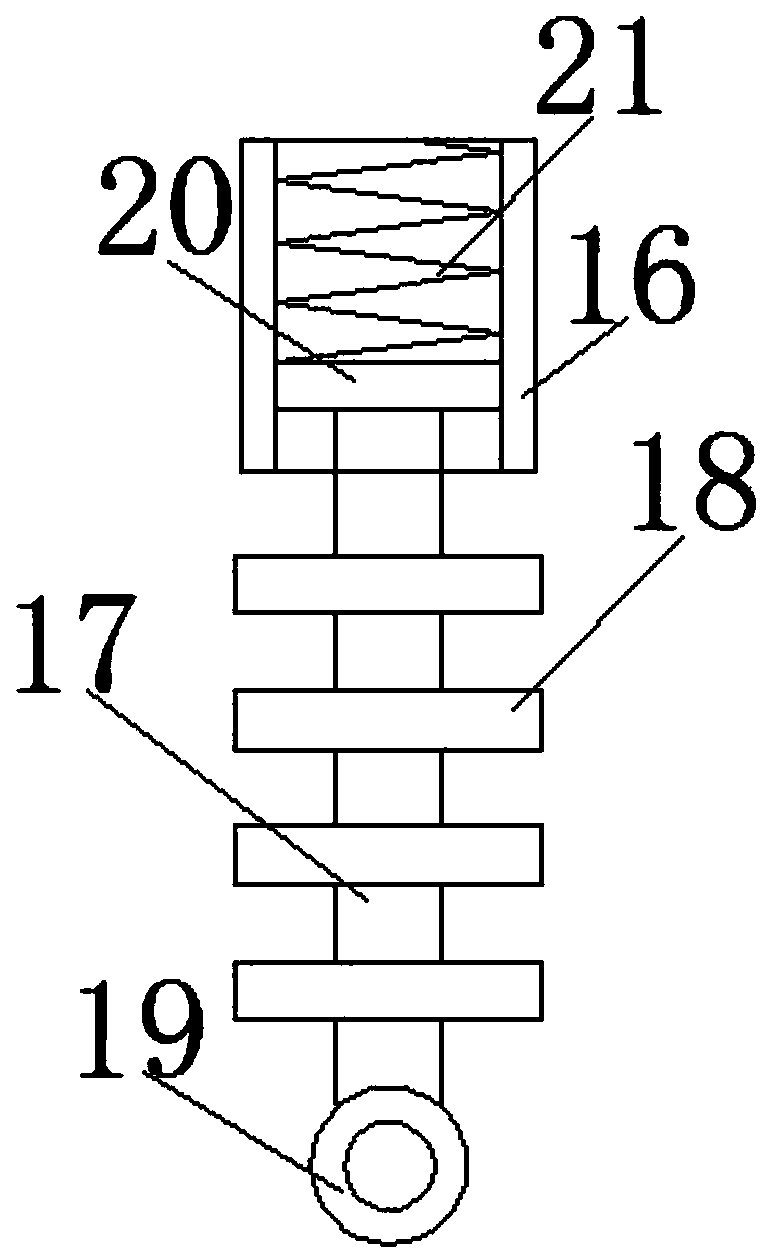

a lift shelf

ActiveCN108542196BEasy to push evenlyPush smoothShow shelvesShow hangersStorage managementSupport plane

Owner:云南鼎好仓储设备有限责任公司

A punching device for switch accessories for motorcycles

The invention discloses a punching device for switch accessories for motorcycles, which includes a punching part for punching holes, the punching part includes a fixed head, a rotating handle, a main punching rod provided with external threads, and a fixed head A secondary punching rod hinged at an acute angle, an AC motor used to drive the rotation handle, a first slider passing through the main punching rod, a second sliding block passing through the secondary punching rod, the first sliding block and The second slider is movably connected through a connecting rod. The first slider is provided with an internal thread that matches the external thread of the main punching rod. Punching, opening large holes with high precision and high efficiency, less damage to switch accessories materials.

Owner:FUZHOU THREEGOLD VEHICLE PARTS CO LTD

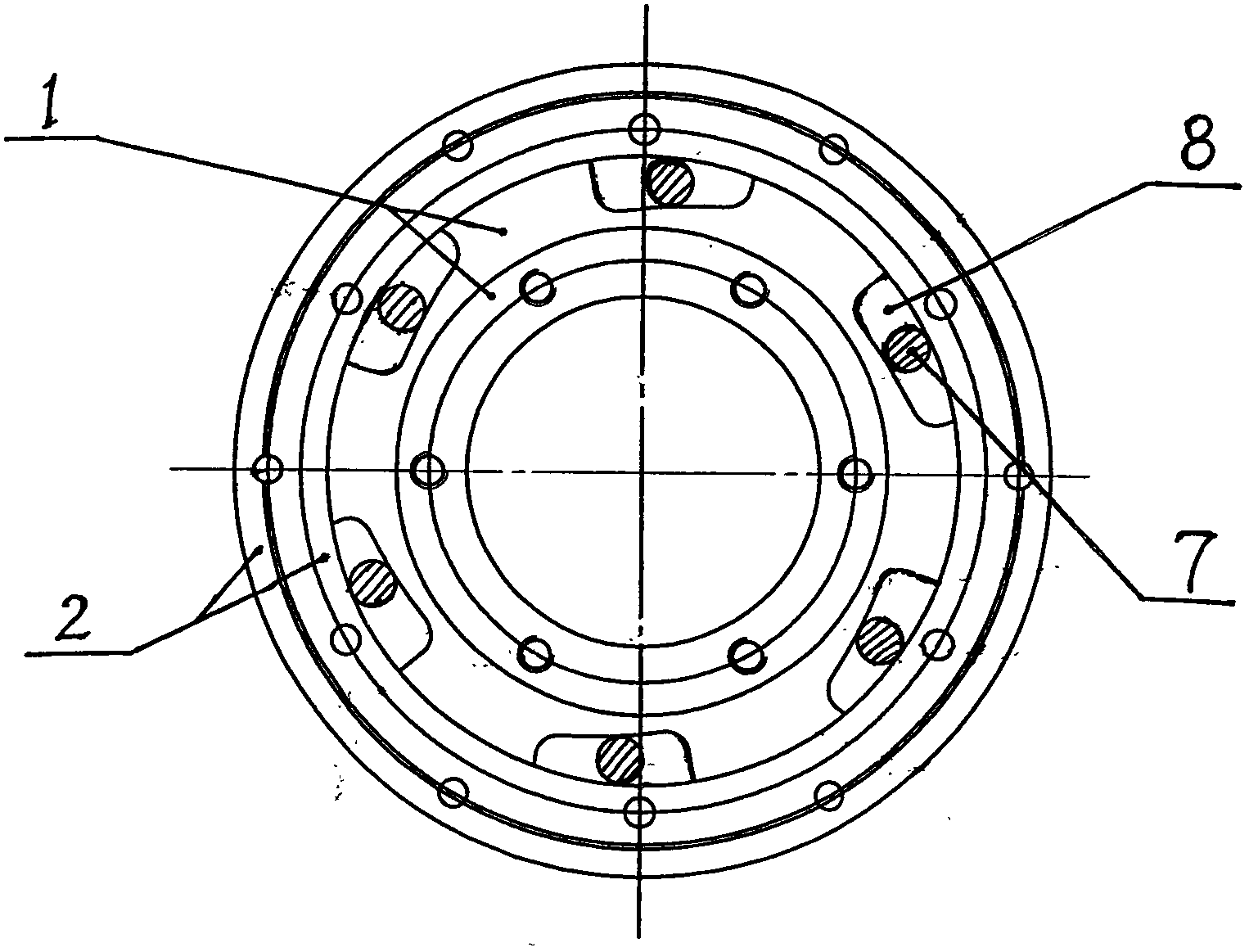

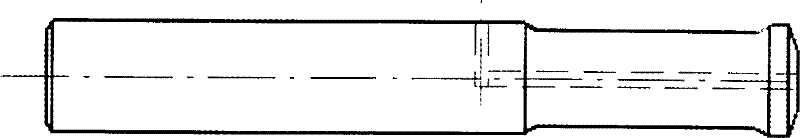

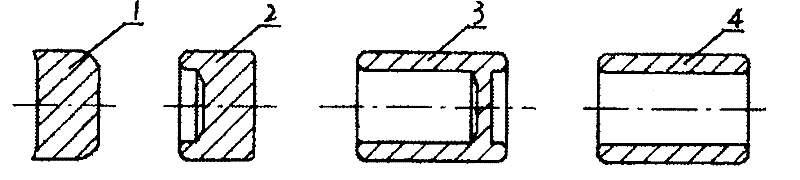

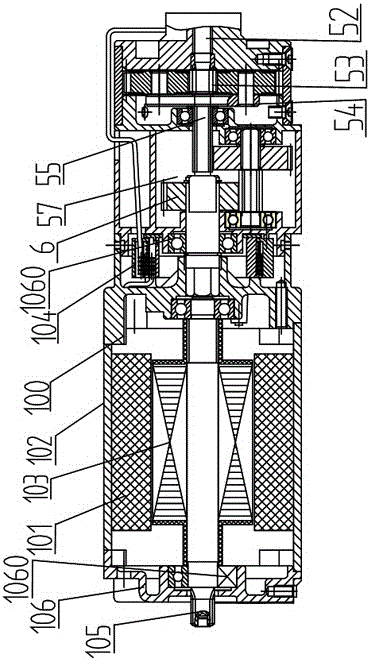

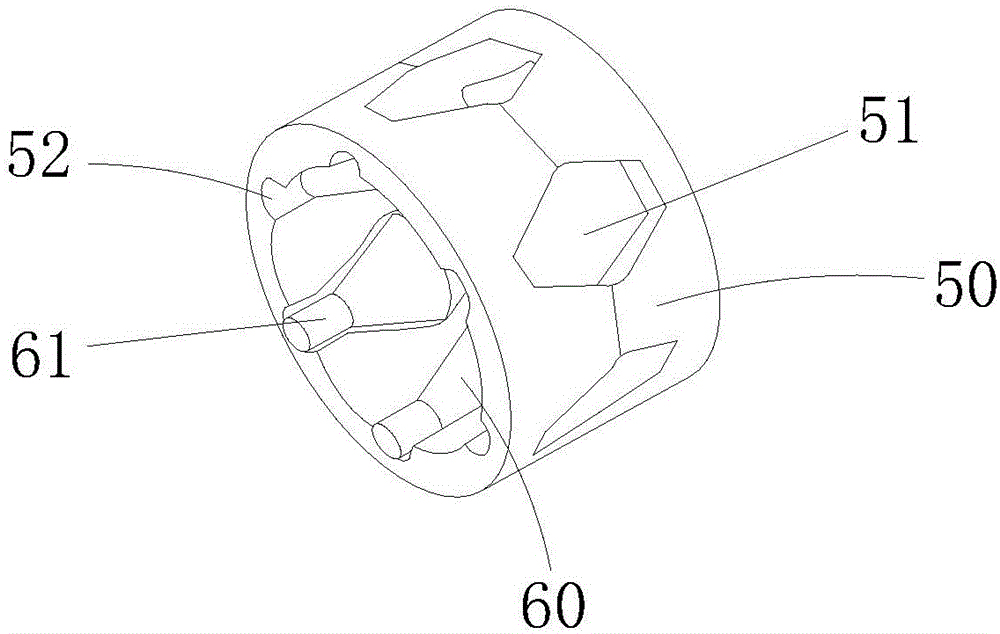

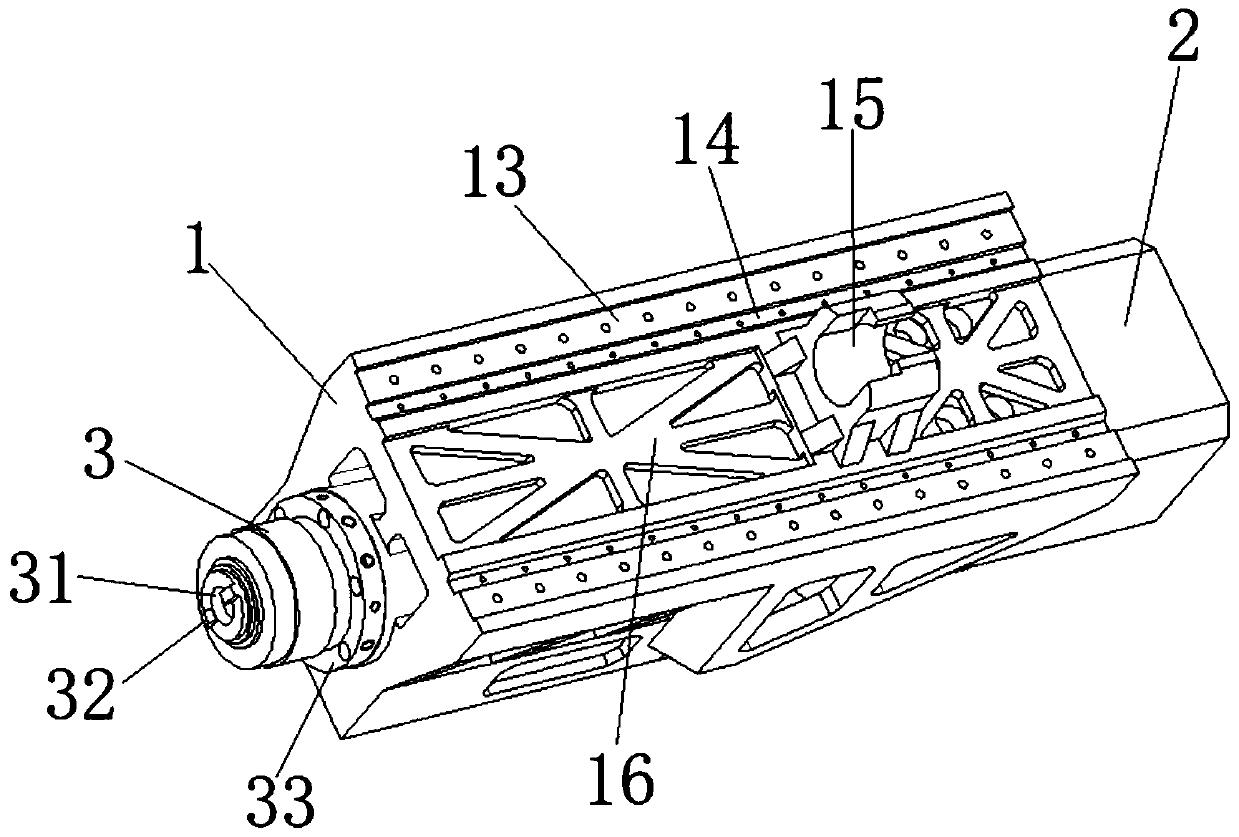

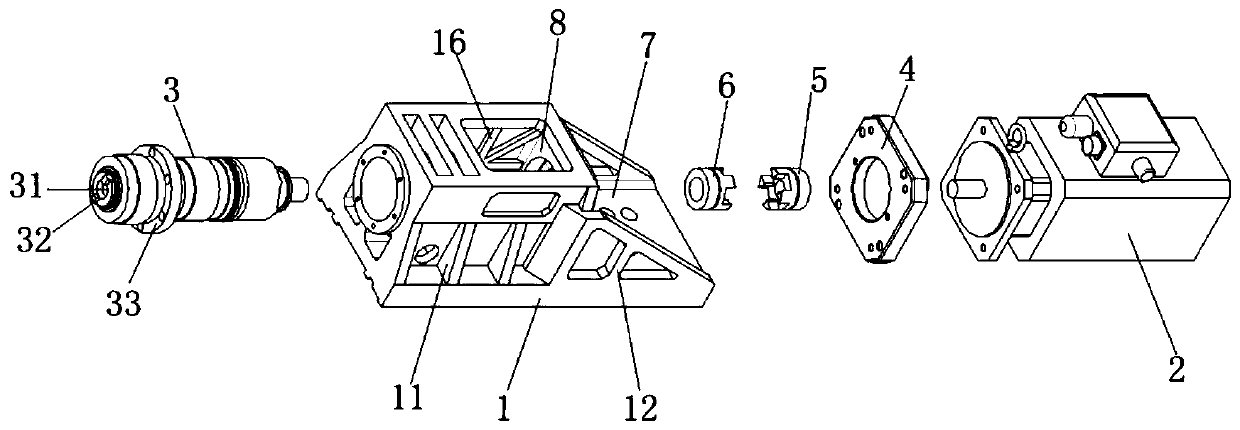

Internal-rotation thinning spinning tool

The invention discloses an internal-rotation thinning spinning tool which comprises an outer shell, an adjusting device, a core sleeve, a core rod, a retainer, a cone-shaped column and two positioning circular truncated cones. One positioning circular truncated cone is fixedly arranged at the end of the core rod, the other positioning circular truncated cone is movably arranged on the core rod, and a pressed concave surface is formed between the positioning circular truncated cones; the cone-shaped column is movably arranged on the retainer and matched with the pressed concave surface in an abutted mode; the core sleeve is arranged on the outer circumferential surface of the core rod in a sleeving mode, and the end surface of the core sleeve is matched with the end surface of the positioning circular truncated cone movably arranged on the core rod in an abutted mode; the adjusting device is fixedly arranged on the outer shell and used by being matched with the core sleeve. The internal-rotation thinning spinning tool has the advantages of being simple in structure, longer in service life and higher in machining precision.

Owner:谢昭远

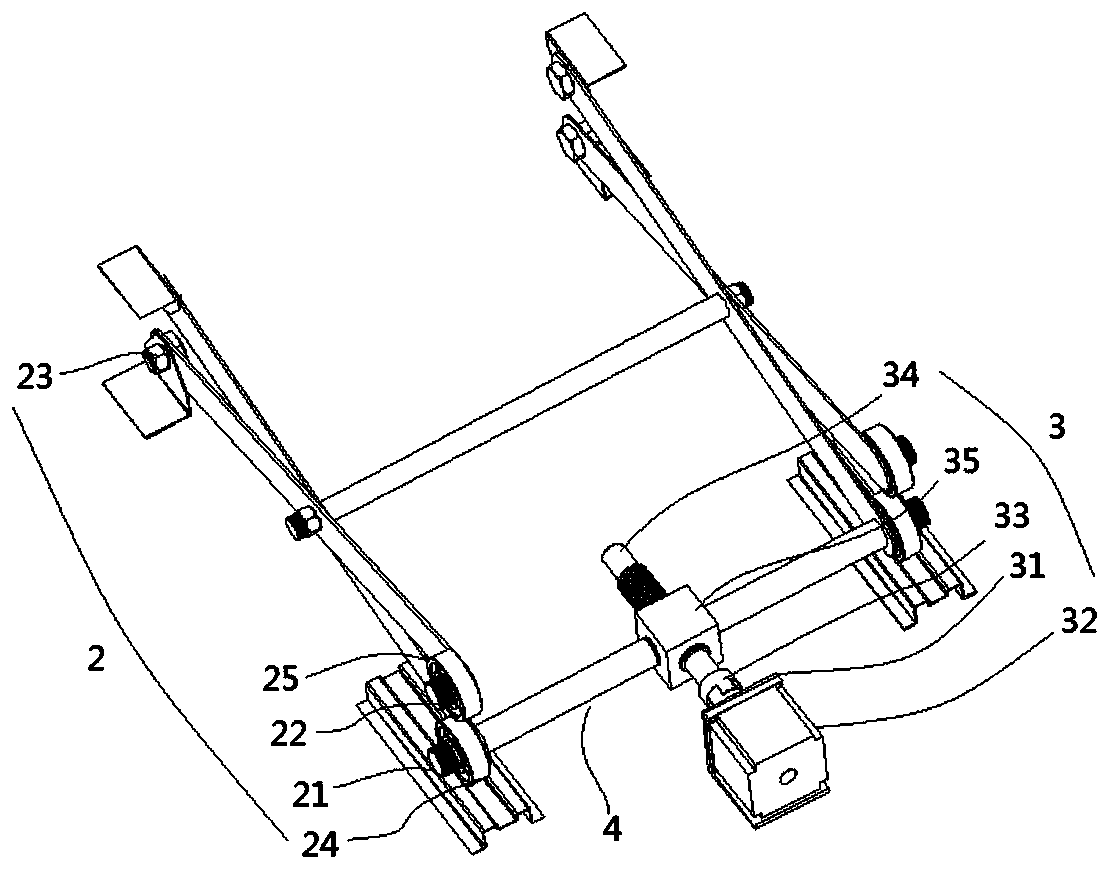

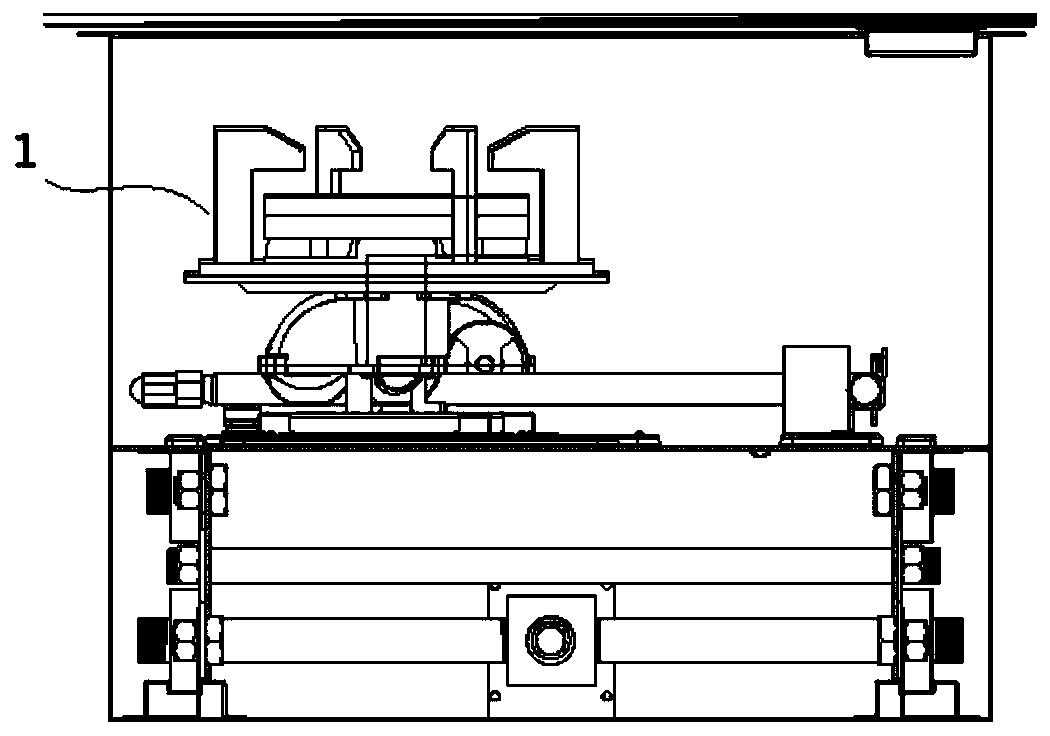

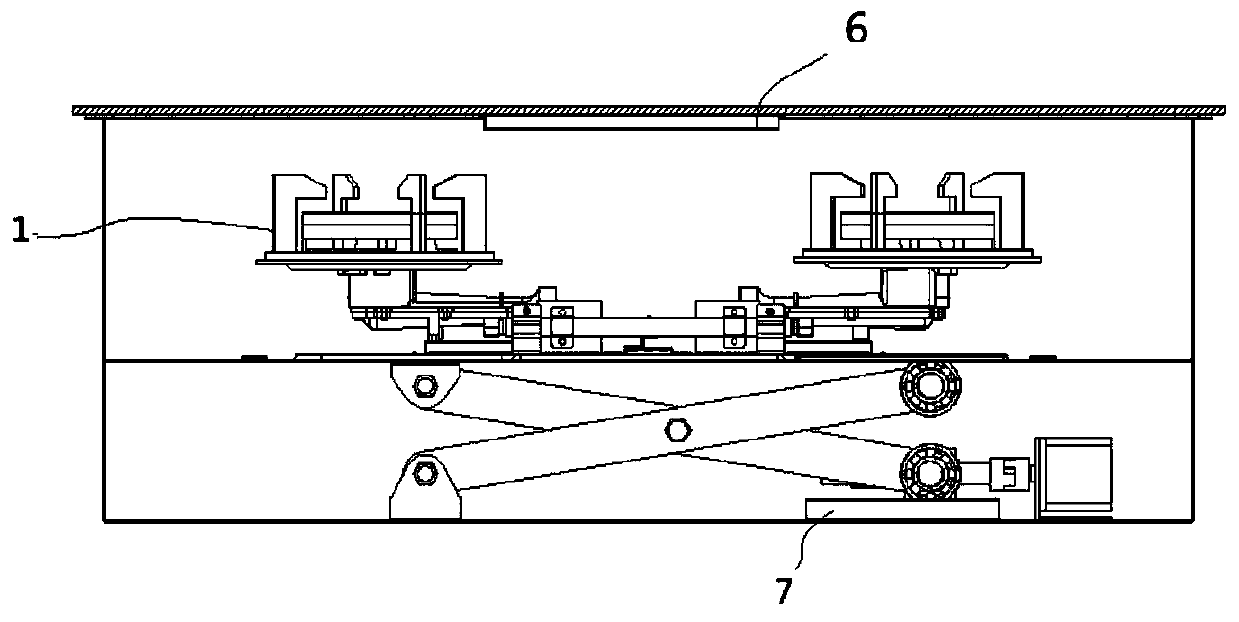

Gas stove lifting device and embedded gas stove

PendingCN110207187AGuaranteed aestheticsSimple structureStoves/ranges foundationsDomestic stoves or rangesEngineeringFoot supports

The invention provides a gas stove lifting device and an embedded gas stove. The gas stove lifting device is used for lifting a gas stove body, at least two scissor foot supports connected to the lower portion of the gas stove body and a drive device are included, wherein each scissor foot support is provided with a driven end movably abutting against the lower surface of the gas stove body and adriving end used for driving the scissor foot support to open and close; and the drive device acts on the driving ends and drives the scissor foot supports to open or close, and accordingly lifting ofthe gas stove body is achieved. The scissor foot supports and the drive device are arranged in the gas stove lifting device, so that gas stove lifting is achieved; and when the cooking process is finished, the drive device can be controlled to drive the gas stove to descend, the gas stove is arranged below a cooking bench to be hidden, and accordingly attractiveness of the kitchen space is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

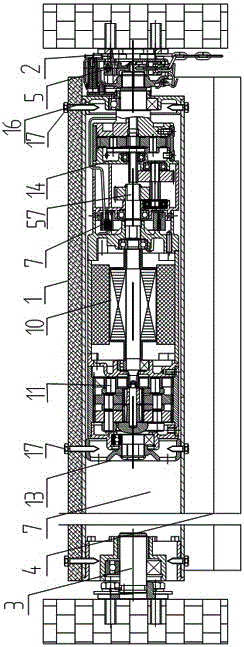

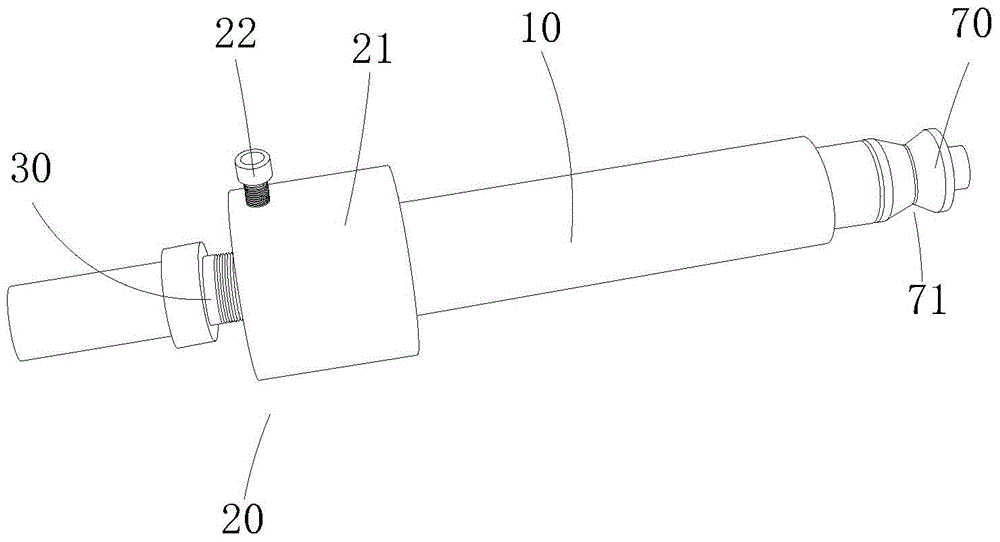

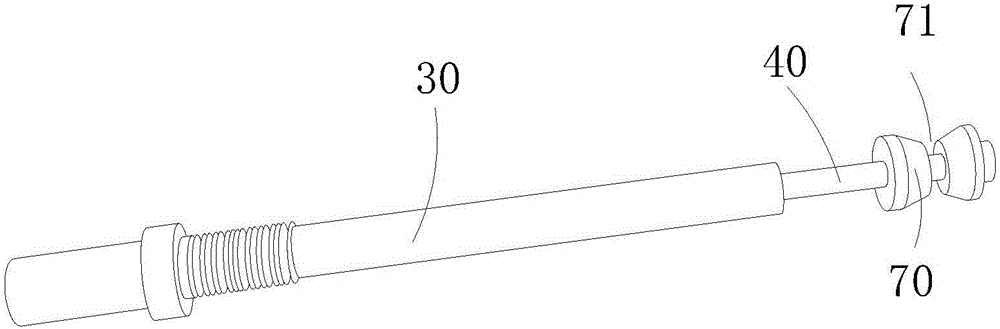

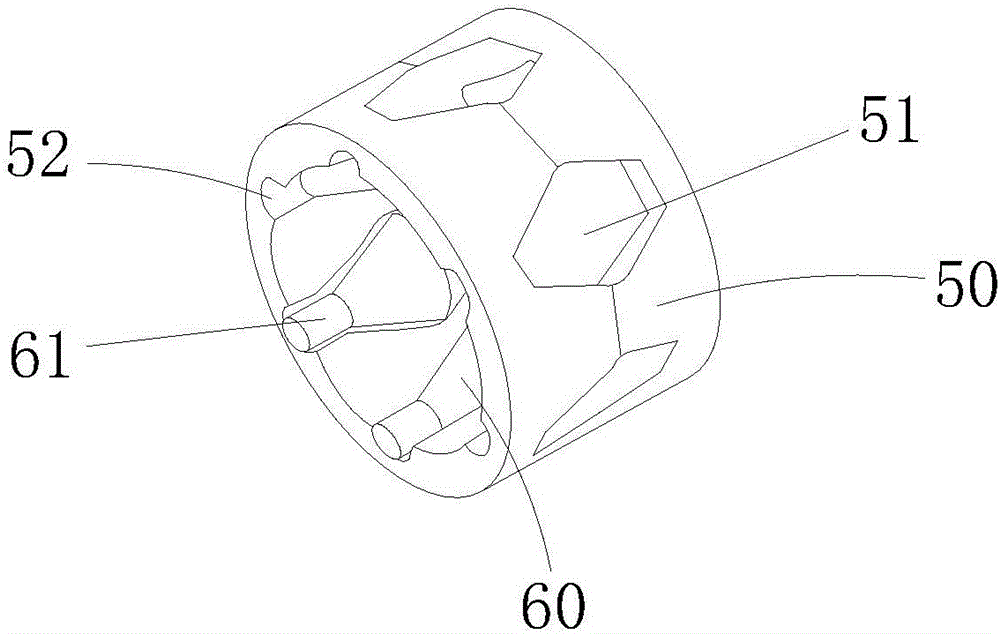

Inner Rotation Thinning Spinning Tool

InactiveCN105107918BExtended service lifeControl the margin of thinning spinningPronationsEngineering

The invention discloses an internal-rotation thinning spinning tool which comprises an outer shell, an adjusting device, a core sleeve, a core rod, a retainer, a cone-shaped column and two positioning circular truncated cones. One positioning circular truncated cone is fixedly arranged at the end of the core rod, the other positioning circular truncated cone is movably arranged on the core rod, and a pressed concave surface is formed between the positioning circular truncated cones; the cone-shaped column is movably arranged on the retainer and matched with the pressed concave surface in an abutted mode; the core sleeve is arranged on the outer circumferential surface of the core rod in a sleeving mode, and the end surface of the core sleeve is matched with the end surface of the positioning circular truncated cone movably arranged on the core rod in an abutted mode; the adjusting device is fixedly arranged on the outer shell and used by being matched with the core sleeve. The internal-rotation thinning spinning tool has the advantages of being simple in structure, longer in service life and higher in machining precision.

Owner:谢昭远

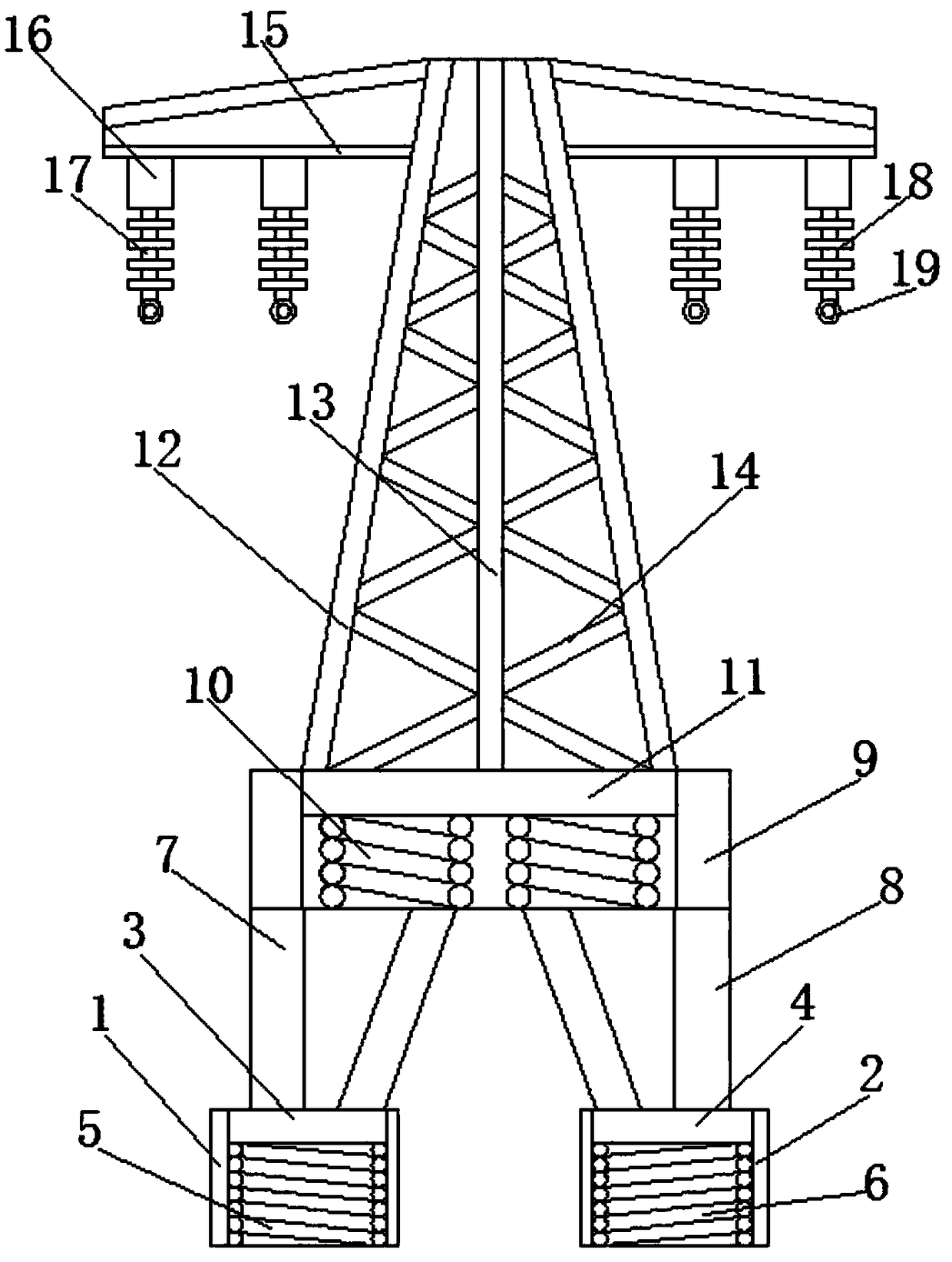

Electric power tower with shockproof function and good stability

InactiveCN108222632AEffective shock-absorbing operationGuaranteed structural strengthTowersProtective buildings/sheltersShock mountElectric power system

The invention discloses an electric power tower with a shockproof function and good stability. The electric power tower comprises a first bracket, a second bracket, a shock mount, an outer tower body,a stabilizer rod, structural rods and a truss. One side under the shock mount is provided with the first bracket, the other end under the shock mount is provided with the second bracket, the outer tower body is arranged above the shock mount, the stabilizer rod is arranged inside the outer tower body, and the stabilizer rod is fixedly connected with the outer tower body by the structural rods. The electric power tower with the shockproof function and the good stability is simple in structure and novel in design, by arranging the shock mount, a first shock absorbing seat and a second shock absorbing seat, shock-absorbing operation to the electric power tower can be carried out effectively, on one hand, vibrations from the ground can be filtered out, and on the other hand, vibrations causedby wind power above the outer tower body can be reduced, so that the structural strength of the outer tower body is ensured and the safety performance is increased; and at the same time, the stability is increased, the service life of the device is further prolonged, and good promotion value is achieved.

Owner:ZHEJIANG JINTA POWER CIRCUIT EQUIP

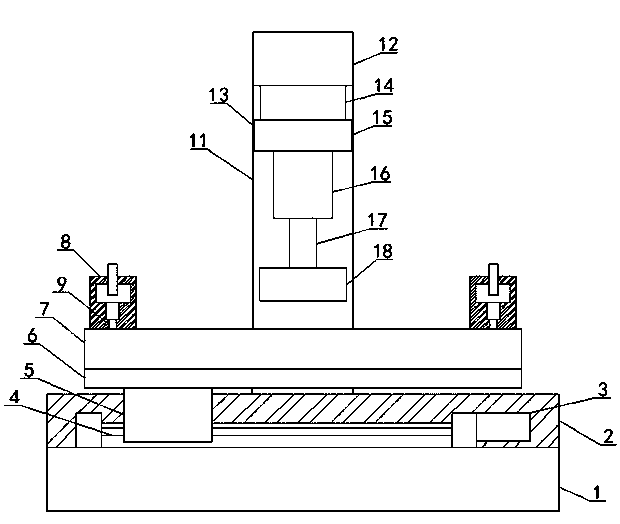

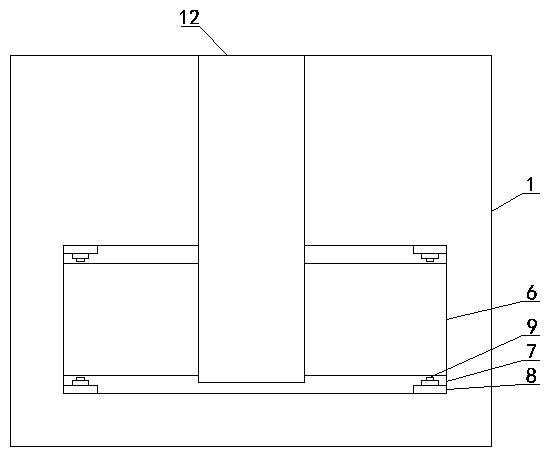

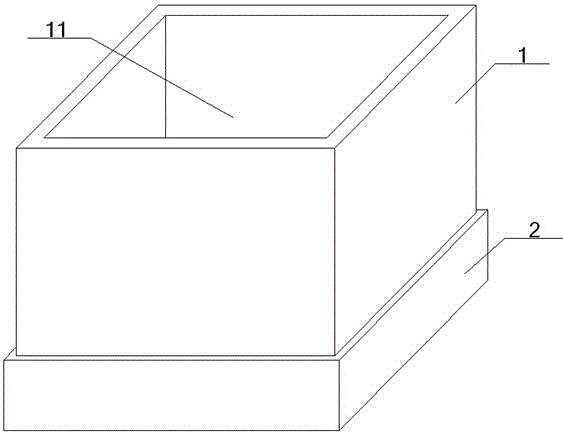

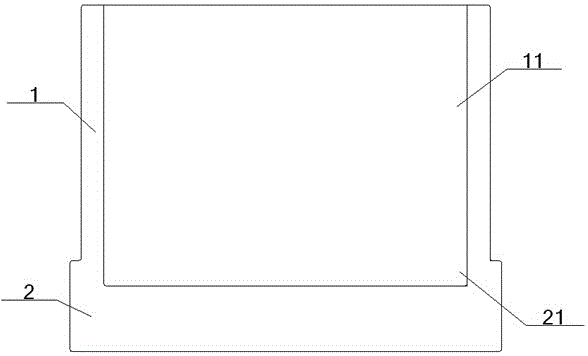

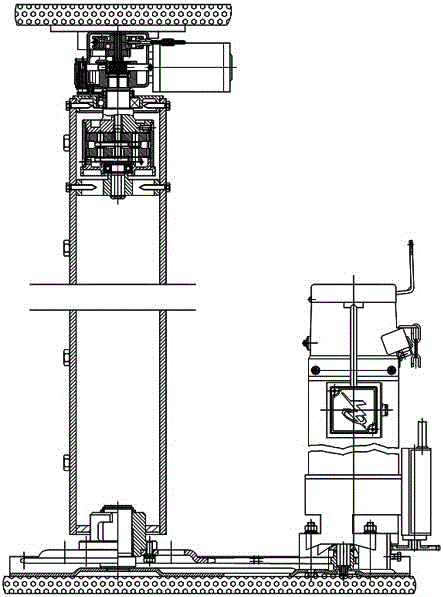

Main shaft box for gantry engraving and milling machine

PendingCN111014736AImprove head rigidityUniform force pointLarge fixed membersPhysicsElectric machinery

The invention relates to the technical field of engraving and milling machines, in particular to a main shaft box for a gantry engraving and milling machine. The main shaft box for the gantry engraving and milling machine comprises a main shaft box which is connected to a door frame of the engraving and milling machine in a sliding manner; the main shaft box comprises a hollow motor chamber, a main shaft chamber, and a guide rail mounting surface which is arranged on the back of the main shaft box; a plurality of first reinforcing rib plates are symmetrically arranged on the outer wall of themain shaft chamber; second reinforcing rib plates are mounted on the inner wall of the main shaft chamber and the guide rail mounting surface; reinforcing frames are symmetrically arranged on the twosides of the motor chamber; a main shaft servo motor is fixedly arranged in the motor chamber through a main shaft transferring plate and a screw; an output shaft of the main shaft servo motor is in transmission connection with a main shaft; and the main shaft is rotatably connected to the interior of the main shaft chamber through a main shaft mounting flange and another screw. Through an integrated design, the main shaft box for the gantry engraving and milling machine is high in stability, improves the roughing capacity of a machine tool, has practical performance and is suitable for popularizing.

Owner:惠州市力玛机械设备有限公司

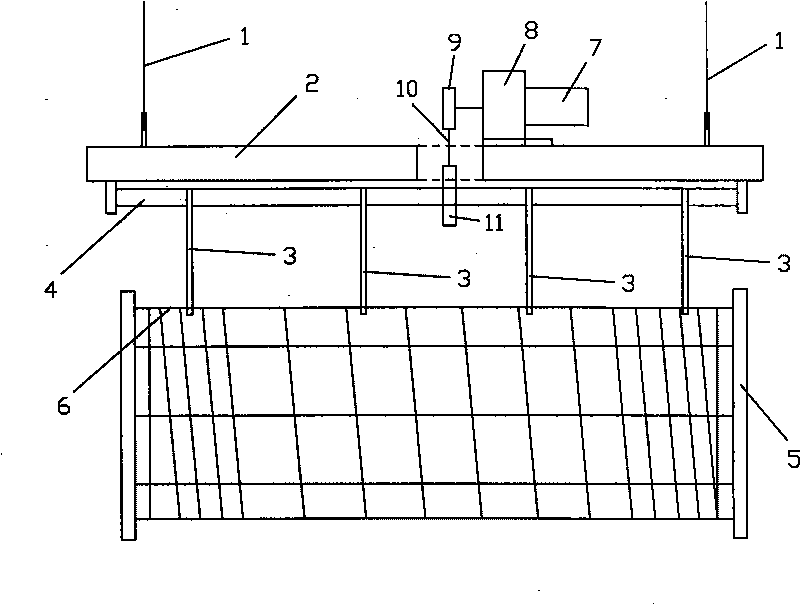

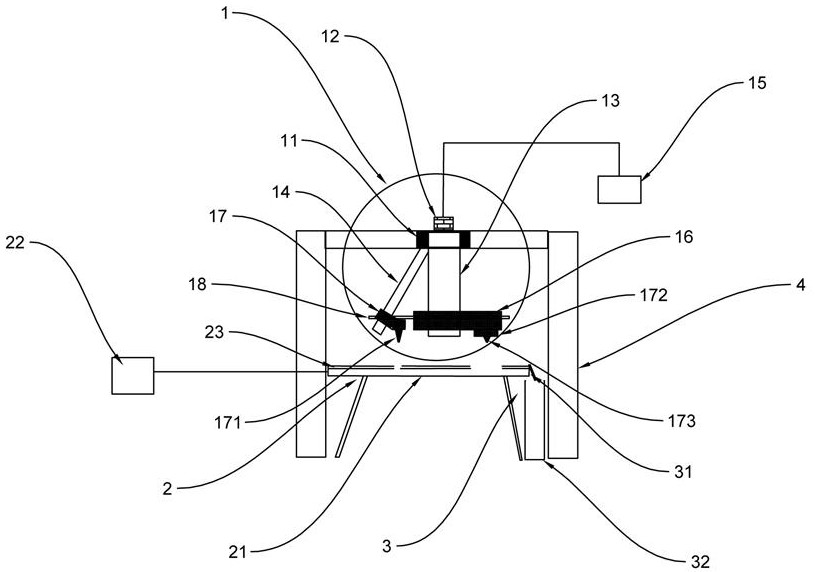

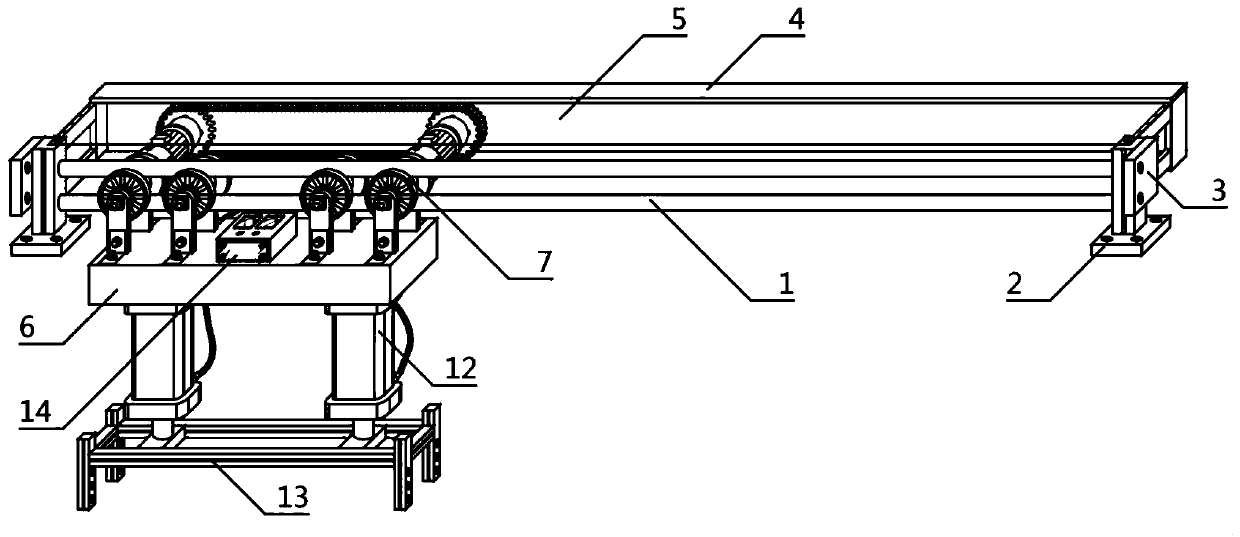

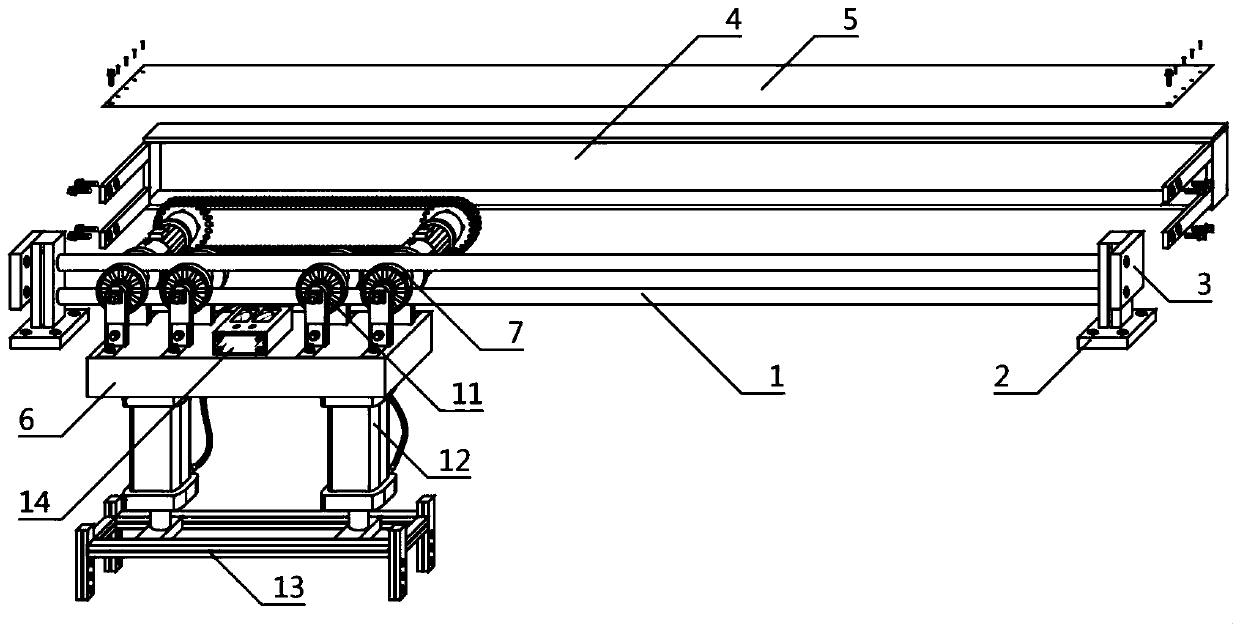

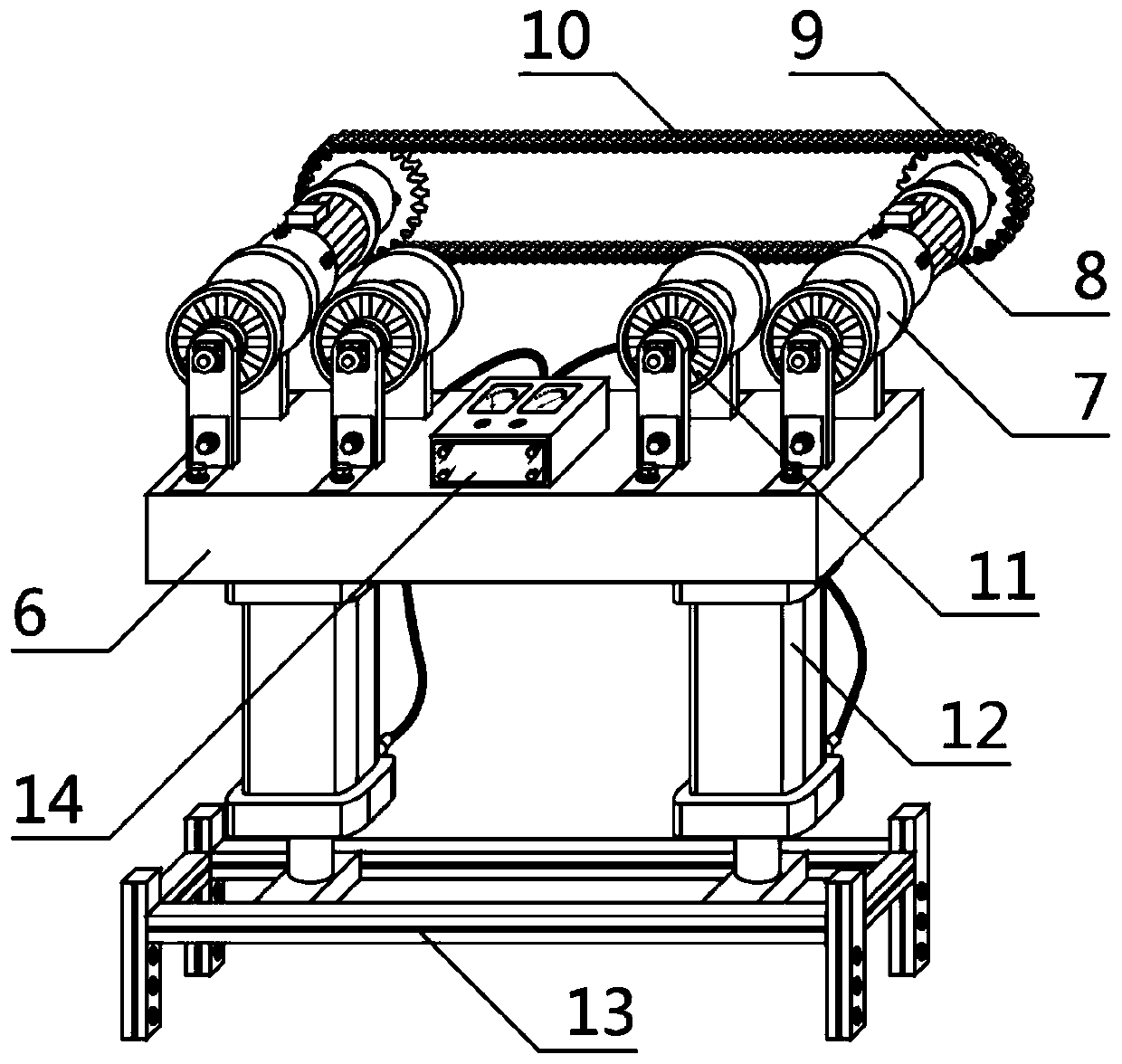

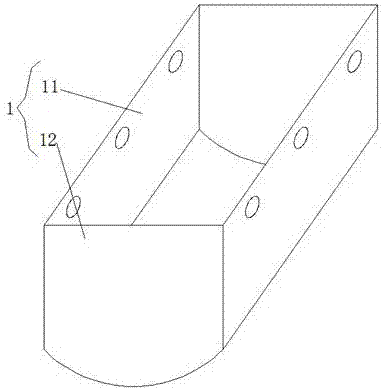

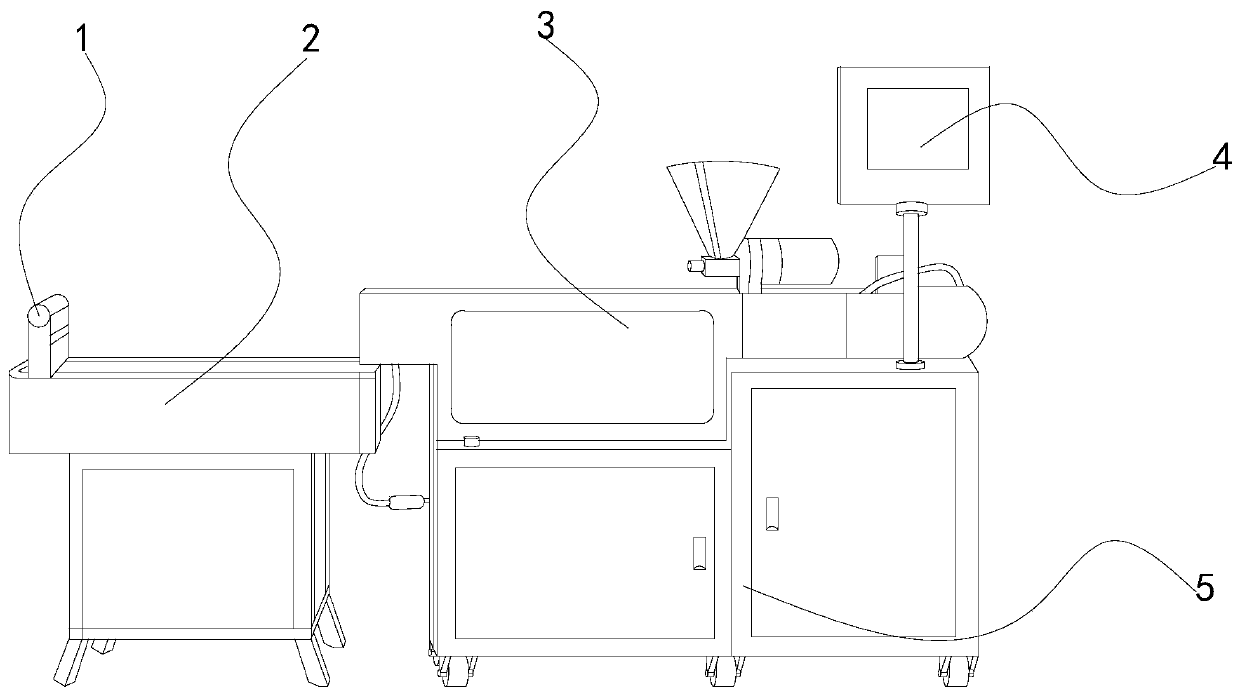

A displacement transmission structure of an inspection robot

The invention aims at providing a patrolling robot displacement transmission structure. According to the technical scheme, the patrolling robot displacement transmission structure is composed of a horizontal track frame, a transmission protection box, a horizontal motion frame, two drive sliding wheels, two auxiliary positioning sliding wheels, two lifting devices, a patrolling device fixing frameand a control box. Each of the two sides of the horizontal track frame is provided with a vertical face fixing plate and a side face fixing plate. The transmission protection box is provided with a cover plate. Each drive sliding wheel is provided with a drive motor, a transmission gear and a transmission chain. According to the mechanism, the hoisting type transmission structure in which the sliding wheels are utilized for fixing and moving, and self movement direction and position displacement control of a patrolling robot can be achieved is adopted; the structure is simple, installation isconvenient, the space used area is small, and components and parts are convenient to detach and replace. The integral horizontal movement and vertical movement stability is higher, displacement is more accurate, noise is low, a short and quiet linkage mechanism is more environment-friendly, the robot patrolling work in various spaces can be finished, and more stability and safety are achieved.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD

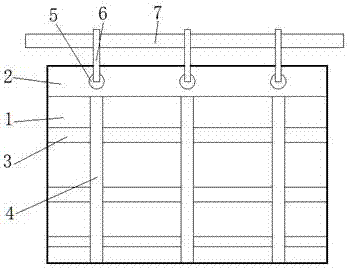

Sealed explosive-proof water bag

InactiveCN107083986ASimple structureImprove stabilityDust removalFire preventionEngineeringBearing capacity

The invention relates to the technical field of explosive-proof water bags, in particular to a sealed explosive-proof water bag. The sealed explosive-proof water bag comprises a water bag body. The water bag body is composed of a main water bag cloth and two side water bag clothes. Connecting plates are installed on the two outer sides of the top of the water bag body, multiple hanging holes are formed in the connecting plates, hanging hooks are connected into the hanging holes in a hung mode, and a hanging beam is jointly inserted into hanging rings of the hanging hooks. Multiple transverse reinforcing ribs are arranged on the water bag body and arranged outside the water bag body at equal intervals, and multiple U-shaped longitudinal reinforcing ribs are connected to the bottoms of the two connecting plates. The explosive-proof water bag is high in stability, the connecting plates are installed on the two sides of the explosive-proof water bag, the connecting plates and the explosive-proof water bag are glued through hot melt glue, the connecting plates and the explosive-proof water bag are glued more stably, the water bag body is supported through the transverse reinforcing ribs and the longitudinal reinforcing ribs, good bearing capacity is achieved, force-bearing points are increased, the force-bearing points are uniform, and the water bag is more durable.

Owner:阜宁县曙光合成革有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com