PET material thin film production equipment

A production equipment and material film technology, applied in the field of PET materials, can solve the problems of PET material film shedding, affecting the degree of film bonding, and large film force, so as to achieve the effect of improving the degree of bonding, slight drying effect, and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

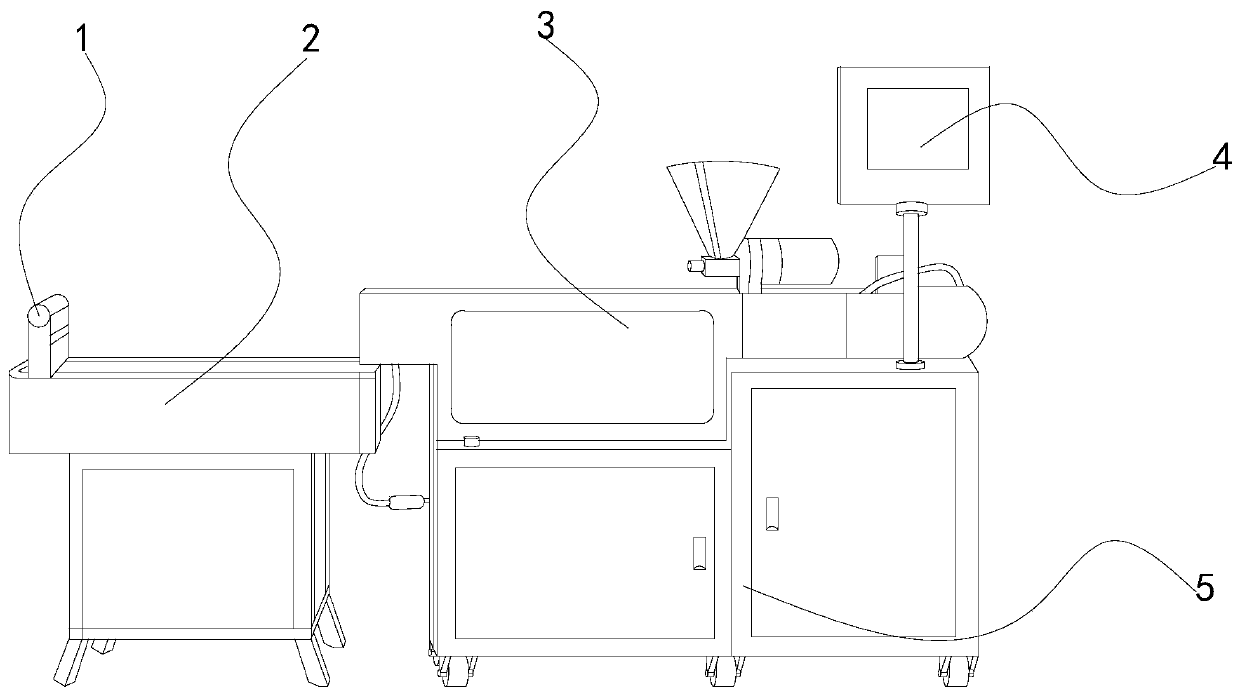

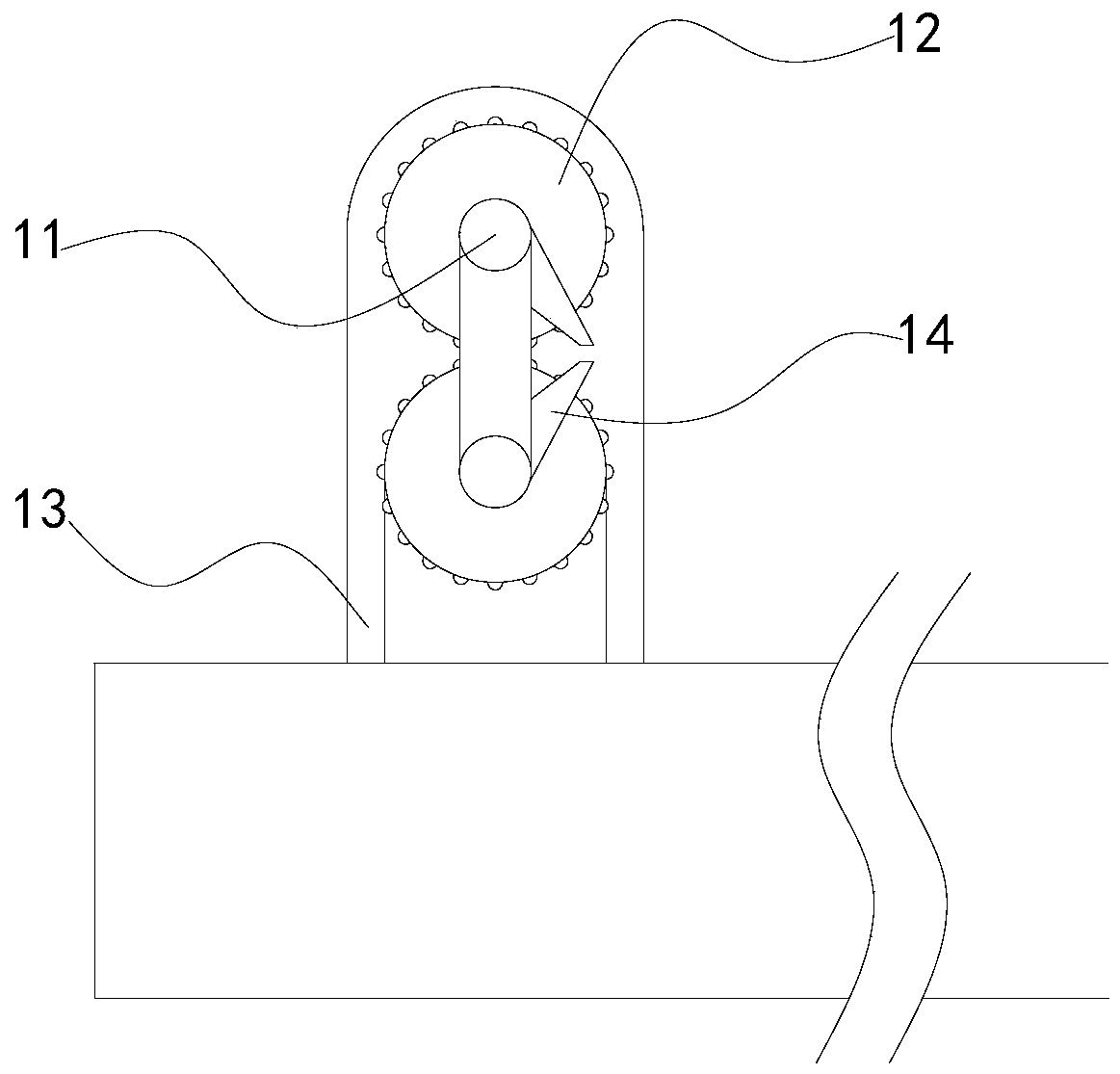

[0023] like Figure 1-Figure 5 Shown:

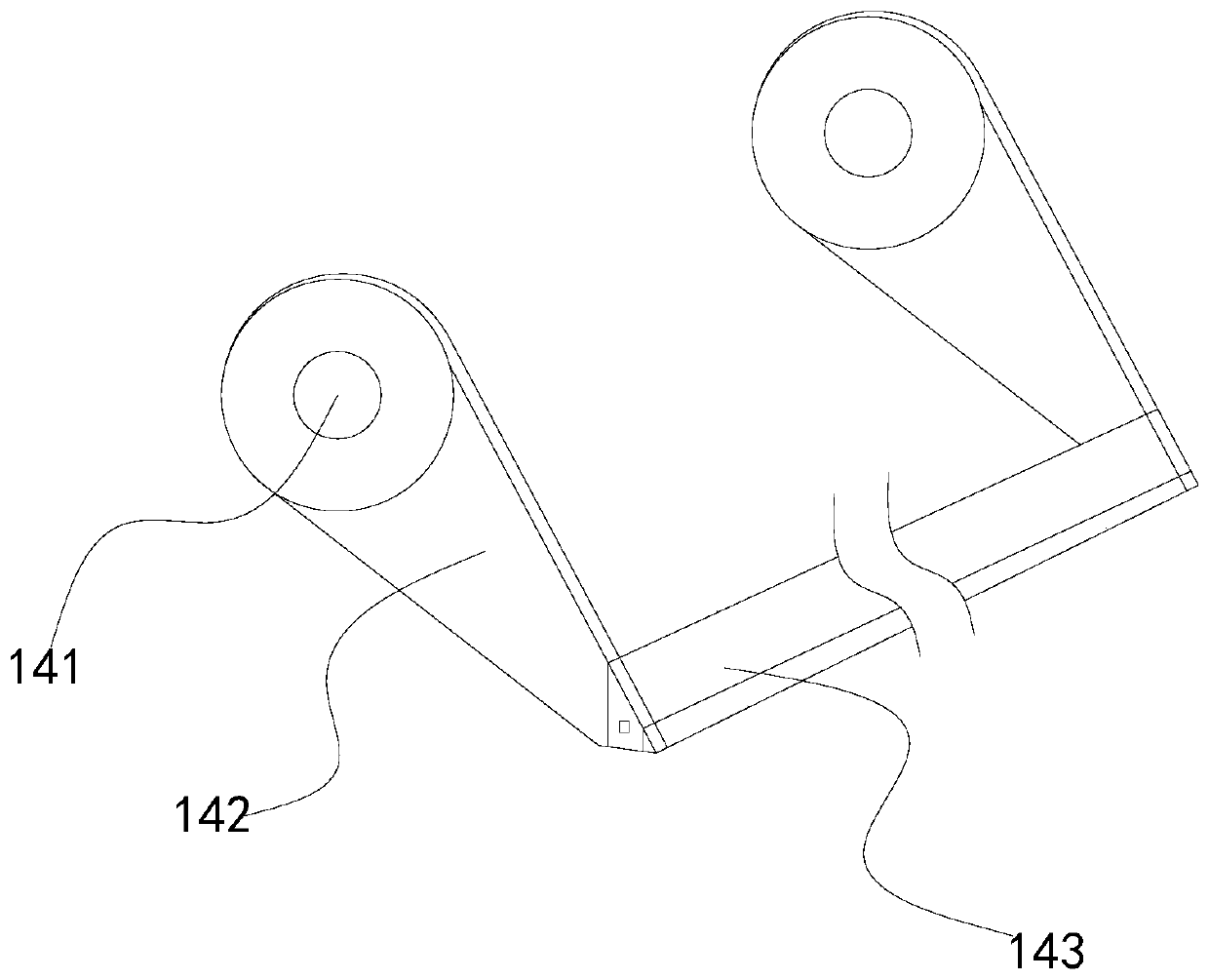

[0024] A kind of PET material film production equipment of the present invention, its structure comprises cleaning mechanism 1, cooling table 2, laminating device 3, control panel 4, placing table 5, the lower end of described cleaning mechanism 1 is welded on the upper end of cooling table 2, so The laminating device 3 is installed on the upper surface of the placing table 5, the control panel 4 is fixed on the upper end of the placing table 5, the right end of the cooling table 2 is located at the left lower end of the laminating device 3, and the cleaning mechanism 1 A fixed rod 11, a rotating shaft 12, a fixed plate 13, and a clearing device 14 are provided, the fixed rod 11 is embedded in the fixed plate 13, the rotating shaft 12 communicates with the fixed rod 11, and the clearing device 14 is embedded Inside the fixed rod 11, the lower end of the fixed plate 13 is welded to the upper end of the cooling table 2, and the rotating s...

Embodiment 2

[0031] like Figure 6-Figure 7 Shown:

[0032]Wherein, the scraping mechanism a24 is provided with an extruding mechanism w1, a hollow groove w2, an absorbing block w3, a rotating rod w4, and a connecting block w5, and the left end of the extruding mechanism w1 is welded inside the connecting block w5, and the absorbing The block w3 fits on the surface of the rotating rod w4, the hollow groove w2 is located at the lower end of the right side of the extrusion mechanism w1, the rotating rod w4 is embedded in the lower end of the right side of the connecting block w5, and the right side of the connecting block w5 is pasted Fitted at both ends of the force-bearing block a25, the absorbing block w3 is made of sponge, and its left side cooperates with the right side of the extruding mechanism w1 to clean the water drops on both sides of the film to avoid the film sticking caused by the water drops. The joint is not smooth to prevent gaps when the film is rolled up.

[0033] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com