Inner Rotation Thinning Spinning Tool

A technology of thinning spinning and tools, which is applied in the field of mechanical processing tools, can solve the problems of limited processing allowance, decreased processing accuracy, and easy dents, etc., and achieves the effects of uniform force points, improved convenience, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

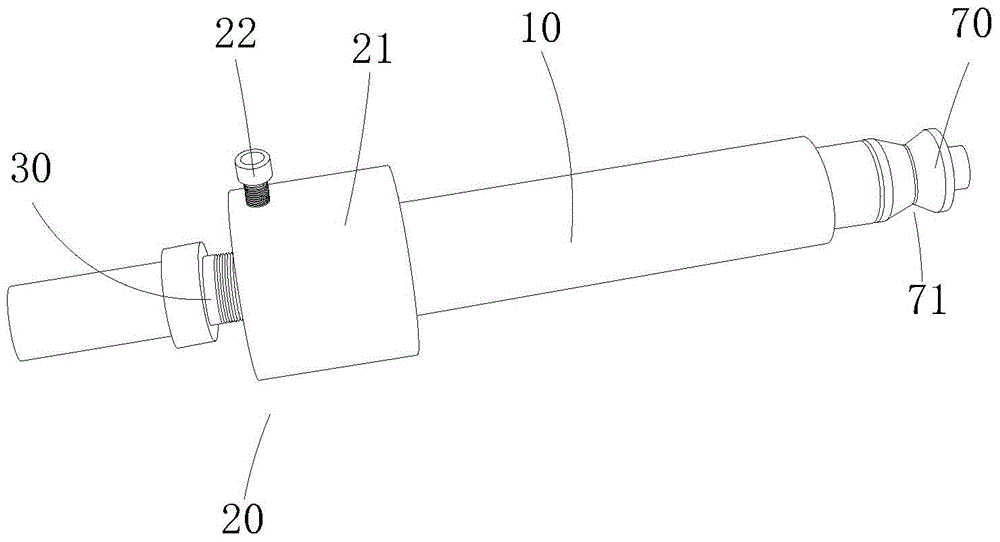

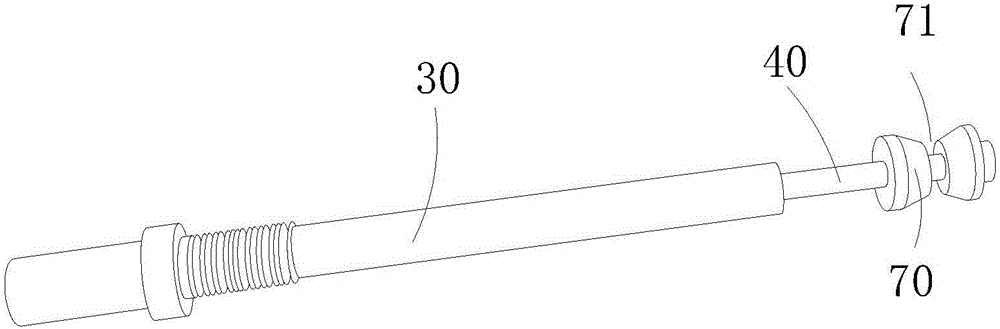

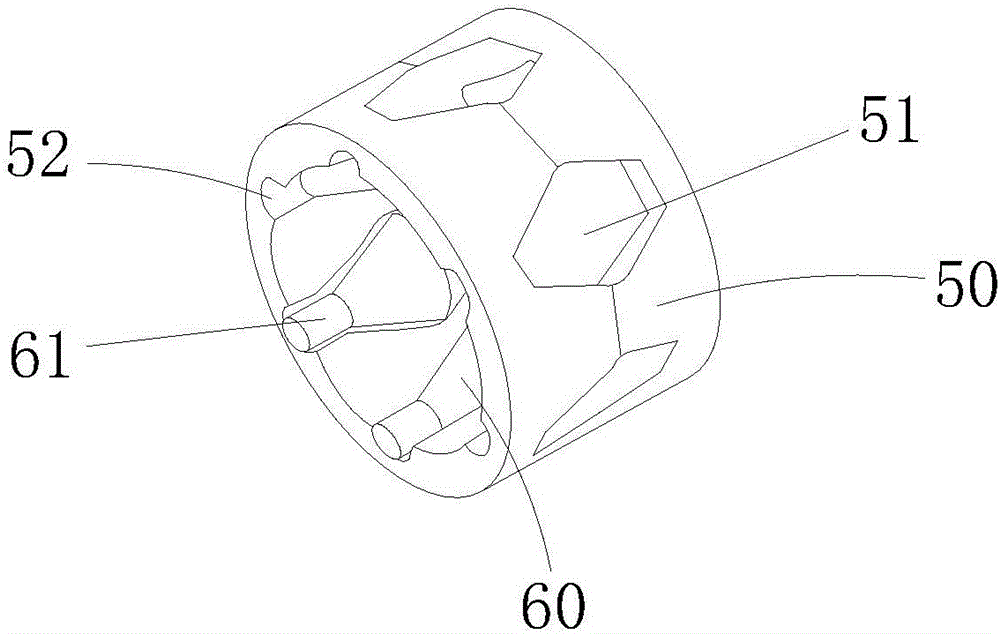

[0014] Examples, see Figure 1 to Figure 4 Shown: an internal rotation thinning spinning tool, which includes an outer shell 10, an adjustment device 20, a core sleeve 30, a core rod 40, a cage 50, a cone column 60 and a positioning round table 70; The hollow structure, the core sleeve 30 is sleeved in the hollow part. There are two positioning round tables 70, one of which is fixedly arranged on the end of the core rod 40, and the other is movably arranged on the core rod 40. This structure setting can facilitate the adjustment of the distance between the two positioning round tables 70, so as to adjust the extrusion of the pipe fittings. The thinning margin can be reduced to achieve better precision requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com